Hello everybody !

What is cold forging?

Cold forging is the manufacture of products during which metal is not thermally heated. The shape we need is obtained as a result of exclusively machining, that is, the metal bends under the action of force. In this article, the author will describe how to use cold forging to make a window grill, which will subsequently be installed in a metal door. For a better understanding, the author attaches a detailed photo report.

We will need the following materials:

- square pipe 20 × 10 mm;

- a circle of steel hot skating with a diameter of 10 mm;

- square steel hot skiing D10 mm;

- decorative metal products;

- 8 mm bolts with a semicircular head - M8 nuts;

- grinding discs for metal;

- automobile soil;

- black paint;

- golden paint;

- solvent 646.

Tool

- grinder;

- welding machine;

- drill;

- roulette;

- ruler;

- a piece of chalk.

Let's get started!

Initially, the author made just such a door, for which a special protective grille will be made.

The first step was to make a special sketch, which later needs to be printed, the dimensions are 1:10.

Next, a square pipe was taken, from which the frame is made, forging elements will be welded to it later on.

The frame needs to be welded with a small indent (10 mm) along the entire contour of the window opening.

Further, on a piece of tin sheet, the author drew a future pattern that will decorate and protect the door window.

Then the author made a special device, with the help of which metal bending will occur, it is very simple, for this you need to take two pieces of round reinforcement with a diameter of 16 mm, and weld them to a free surface, make the distance between the rods 10 mm, so that the rod that we will bend is free lay between them. Next, bend the shape of the vine.

When all the elements are ready, we weld them to the frame, so that the seams are not visible, we cook everything from the inside of the frame, then grind it with a grinder.

In order to give the product a forging effect, the author took ready-made decorative elements, cutting off the petals with a grinder and welded them at the ends of the vine

Next, the remaining elements were welded

We make a frame for the frame. To do this, you need to take a square pipe, weld one of the ends, and from the other end you need to weld a piece of a round rod, then we start to rotate, the pipe will gradually twist.

In order to fix the frame with the elements of the vine, you need to drill 4 holes in the corners with a drill with a diameter of 8 mm, then in the finished holes you need to place the bolts with a round head.

After the frame is fixed, we draw a pattern in the upper and lower parts.

Twisted square pipes need to be shortened a little, then decorative elements are welded to them, according to the example in the photo.

Next, grind the joints with a grinder.

Since the upper part should be slightly smaller, we bend the rod with the help of a pipe, we use the effect of the lever.

We connect the finished parts by welding, then grind.

Similarly, we do with the bottom.

We weld furniture bolts on the reverse side of the structure.

Next, in several places we drill holes, insert a bolt of the appropriate size and cut off the excess part with a grinder, and then weld, thus creating the forging effect.

The window grill is ready, it remains to paint. To do this, first degrease the surface with a solvent, then apply a primer, and then paint it.

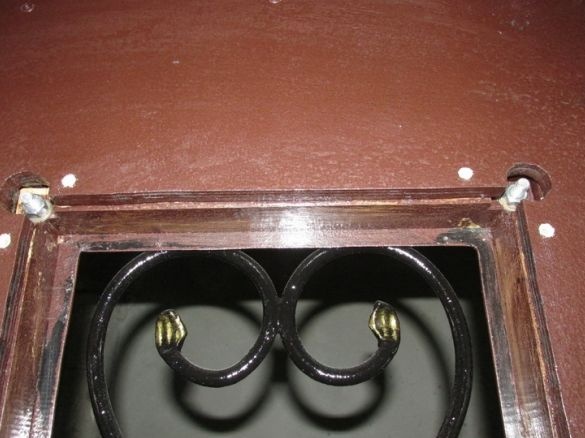

It remains to fix the grille to the door. Fasten the forged grill with nuts on the back side.

The edges of the vine and the caps of the bolts are painted with gold paint.

That's how it looks in the finished version.

Thank you all for your attention!