We all love to cook food on fire, as such food has its own unique taste, which can not be compared with anything else. In this article, the author will tell you how to make a special device for these purposes, it will turn out universal and will include a smokehouse, barbecue grill and barbecue. The entire manufacturing process is described in detail, and is accompanied by a full photo report.

The peculiarity of this smokehouse is that the hearth is located separately from the smoking chamber, that is, the products are smoked exclusively in smoke, so there will be no overheating.

The smoking chamber can be made from a gas cylinder, an expansion tank, or from a pipe of large diameter. It is advisable to take a thickened metal, as it can burn out over time.

To make a smokehouse, we need:

Materials:

- gas bottle;

- for the source - metal from 6 mm thick;

- steel corners and profile pipe for the frame;

- four wheels;

- ventilation flaps;

- pipe;

-thermometer;

- loops;

- wooden handle;

- shelf for dishes;

- heat resistant paint.

Tool:

- welding machine;

- grinder;

- pliers

- hammer;

- metal brush;

- protective equipment.

To begin with, we will manufacture the frame, the smokehouse itself will be installed on it in the future, we will cook it from the corners, according to the intended sizes. Further, so that the smokehouse can move in the lower part of the frame we fasten the rollers.

Then we take a cylinder and with the help of a grinder we cut off one side part, through this opening smoke will enter the smokehouse. Next, mark the outline of the window and cut it out. When everything is ready, we make a door from the cut-out part, use loops that we fix with bolts.

Along the entire contour of the window, we install an aluminum seal, we fix it with rivets.

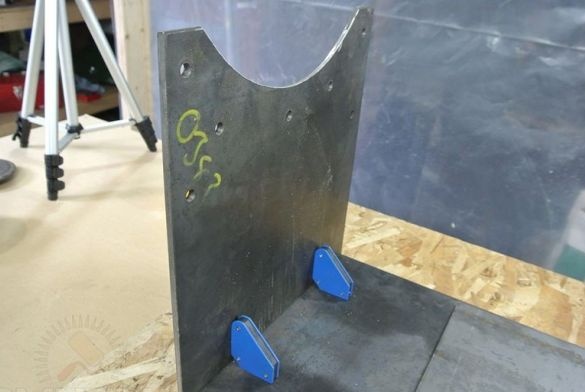

Now we proceed to the manufacture of the combustion chamber, we take sheet metal with a thickness of 6 mm, we cut metal walls from it, which we then weld to each other, we also install the door, which we fix on the hinges. The left wall of the combustion chamber must be made with a small semicircle in the upper part, we make it according to the shape of the cylinder. This hole is necessary so that the heat and smoke from the hearth are evenly distributed throughout the smokehouse.

On the side of the camera in the lower part we drill a lot of holes, they are needed for ventilation. Next, we fix a special flap next to it, which will regulate the air intake.

Now we make a mechanism that will close the combustion chamber. Everything is shown in detail in the photo.

A spring was taken as a handle for closing the ball chamber, which was fixed by welding.

In order to facilitate the movement or further storage of the smokehouse, it was decided to make the combustion chamber removable, for this a metal plate was cut and welded to the cylinder, and special holes for bolts were made in it. Similar holes must also be made in the side of the combustion chamber. When everything is ready, we attach the camera to the plate, we use bolts as a fixing element.

Next, inside the container, we weld two horizontal corners at the same level, a lattice will be laid on them, on which products will be prepared in the future.

In order for the smokehouse to have good smoke circulation, we make a special chimney. We take a metal plate, which we apply to the cylinder and apply the marking, as shown in the photo, make a hole for the flange. You can buy it, or make it yourself from a narrow plate that needs to be bent in the shape of a circle, and then welded to the intended place.

When everything is cut, we weld this part to the cylinder.

We put a knee on the manufactured flange, then we put a vertical piece of pipe, which will act as a chimney.

In order to know the temperature inside the smokehouse, and to further monitor it, we install a thermometer.

We make a special basket for firewood, which will be placed directly in the combustion chamber.

Next, we make a handle for the lid of the smokehouse, we install two aluminum staples on which we fix the wooden rail.

Now you can proceed to painting the product, but before that you need to thoroughly clean everything from rust, and remove all the debris that has accumulated during the manufacturing process. We paint the surface with special heat-resistant paint. When everything dries, we get just such a multifunctional smokehouse.

Now the smokehouse can be used for its intended purpose, but before you place the first products, the smokehouse should be allowed to warm up well, for this we will light the fire and wait until the remaining oil and paint burn out, as they can give us an unpleasant smell.

You can start the smoking process.

Bon Appetit everyone.

Video with an example of manufacturing:

Thank you all for your attention!