In my free time I practice all kinds of Arduino projects. Quite often for the implementation of a project requires robot - A platform that meets a number of requirements: free movement, the ability to install additional equipment and expand capabilities, as well as moderate cost. Here is such a robot platform or, simply, a caterpillar chassis I will do. Of course, I am posting the instruction to you for trial.

We will need:

- Tamiya 70168 dual gearbox (can be changed to 70097)

- Tamiya 70100 set of rollers and tracks

- Tamiya 70157 platform for attaching the gearbox (can be replaced with a piece of plywood 4 mm)

- Small pieces of galvanized sheet

- Plywood 10 mm (a small piece)

- Arduino Nano

- DRV 8833

- LM 317 (voltage stabilizer)

- 2 LEDs (red and green)

- Resistors 240 Ohms, 2x 150 Ohms, 1.1 kOhms

- Capacitor 10v 1000uF

- 2 single row combs PLS-40

- 2 PBS-20 connectors

- Inductor 68mkGn

- 6 NI-Mn 1.2v 1000mA batteries

- Connector dad-mom two pin to wire

- Wires of different colors

- solder

- Rosin

- soldering iron

- Bolts 3x40, 3x20, nuts and washers for them

- Bolts 5x20, nuts and reinforced nuts to them

- drill

- Drills for metal 3 mm and 6 mm

Step 1 cut the metal.

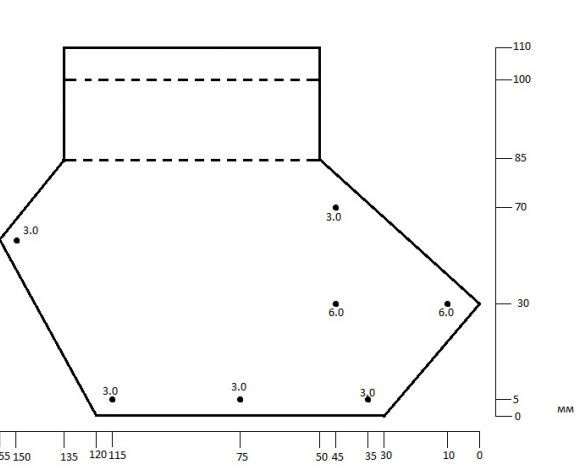

First, we need to cut from sheet metal (preferably galvanized) to cut four parts. Two parts per track. For this scan, we cut out two details:

The dots indicate the places where it is necessary to drill holes, the diameter of the hole is indicated nearby. 3 mm holes are needed for hanging with a roller, 6 mm for passing wires through them. After cutting and drilling, you need to file through all the edges without leaving sharp corners. Bend along the dashed lines 90 degrees. Be careful! We bend the first part in any direction, and the second bend in the opposite direction. They must be symmetrically bent. There is one more nuance: it is necessary to drill holes for self-tapping screws that fasten our plates to the base. Do this when the base is ready. We put the blank on the base and mark the drilling places so that the screws fall into the center of the chipboard. We do two more details on the second scan:

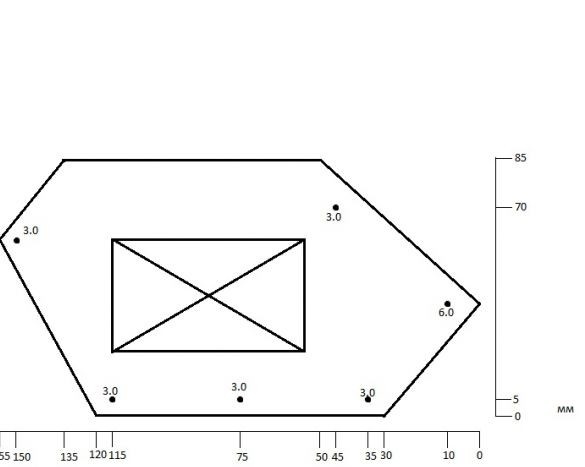

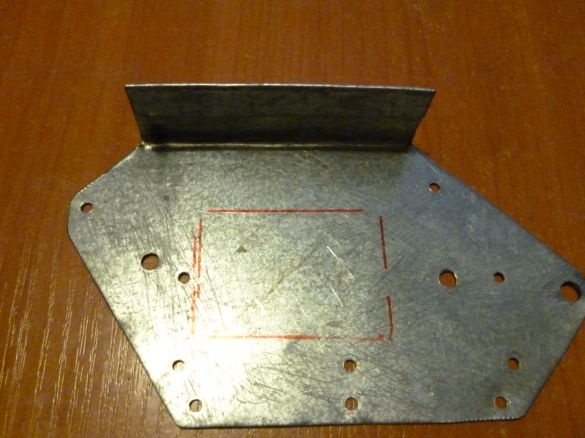

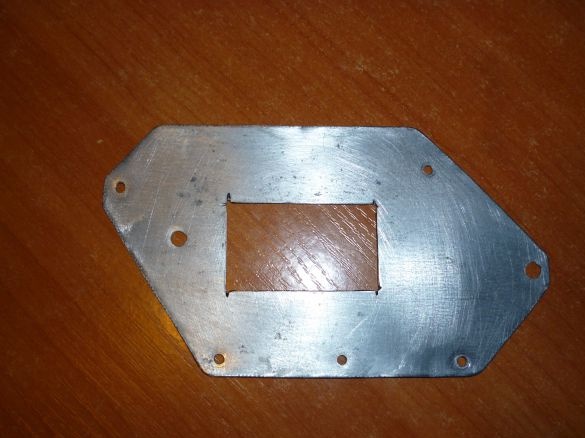

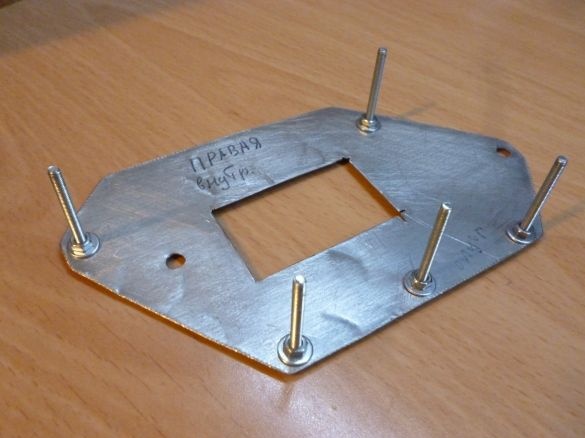

The inner rectangle must be cut. Next, we do the same thing, cut, drill, clean. And in the end we get the blanks:

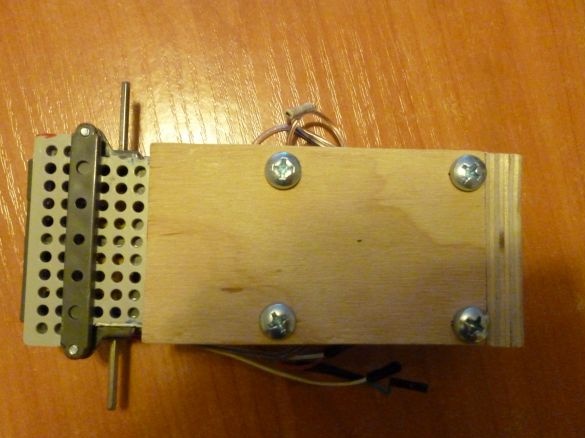

Step 2 prepare the basis.

We assemble the gearbox according to the attached instructions. We fasten it to the site. If there is no platform, we cut a 53x80 mm rectangle from plywood 4 mm and fasten the gearbox to it. Take 10 mm plywood.Cut two rectangles 90x53 mm and 40x53 mm. Inside the small rectangle, we cut out another rectangle, so that we get a frame with a wall thickness of 8 mm.

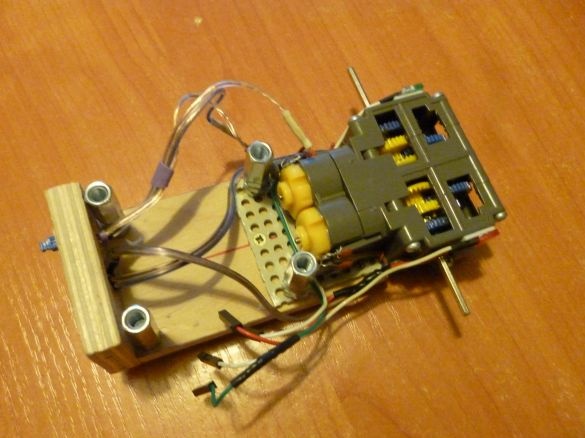

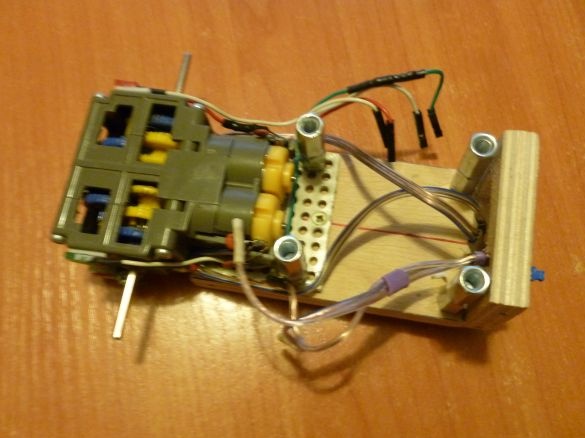

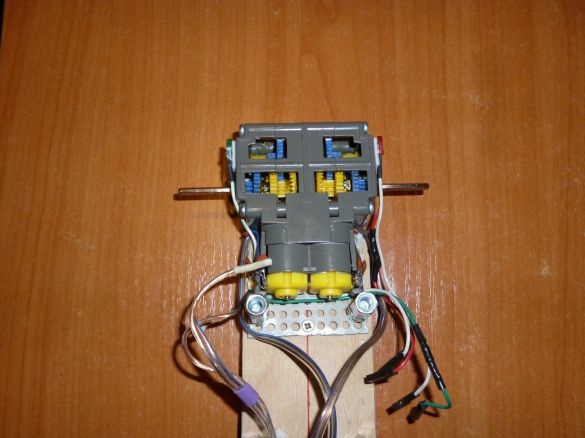

Twist everything as shown in the photo:

In the corners of the platform, drill holes of 6 mm and insert our 5x20 bolts into them; from above we wind reinforced nuts. They are needed for subsequent mounting of various mechanisms or boards. For convenience, we immediately glue the LEDs:

Step 3 is an electrician.

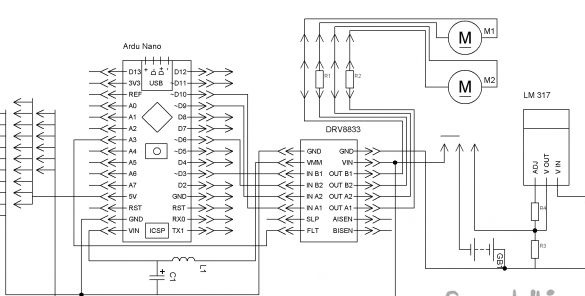

For control we will use Arduino Nano. DVR 883 engine driver. On the circuit board, we assemble everything according to the scheme.

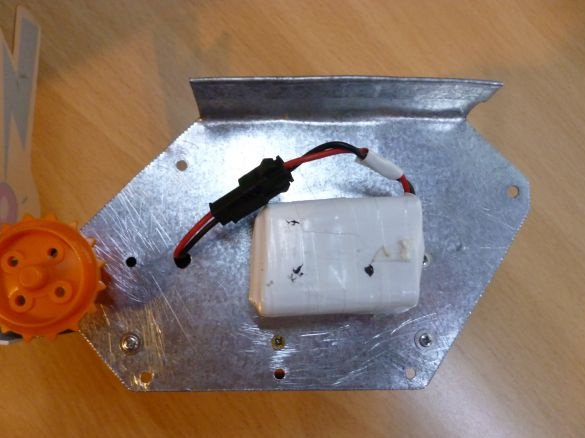

L1 is an inductor and C1 is needed to stabilize the Arduino voltage. Resistors R1 and R2 in front of the motors are current-limiting, their rating must be selected for specific motors. They work fine for me at 3 ohms. LM317 is needed to charge the batteries. The input can be supplied with voltage from 9.5 V to 25 V. R3 - 1.1 kOhm R4 - 240 Ohm. The “pins” on the left are used for subsequent connection of various devices (Bluetooth, 433 MHz communication module, IR, Servo, etc.). For power we will use 6 Ni-Mn 1.2v 1000mA batteries soldered in series and wound with electrical tape.

Step 4 we collect the basis.

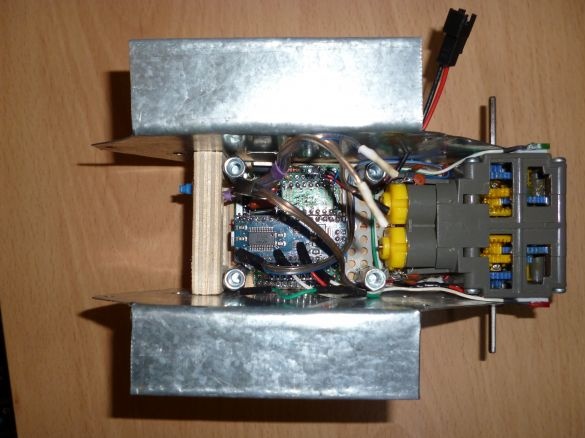

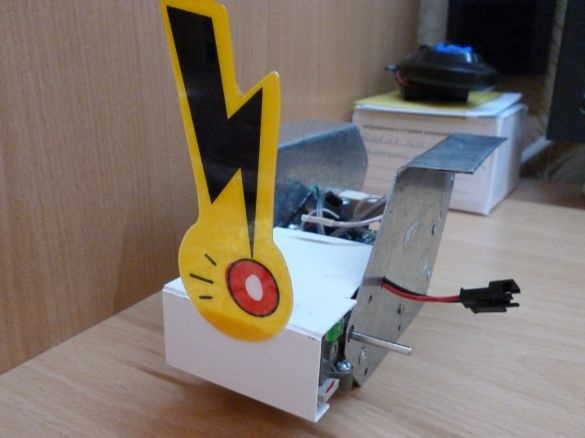

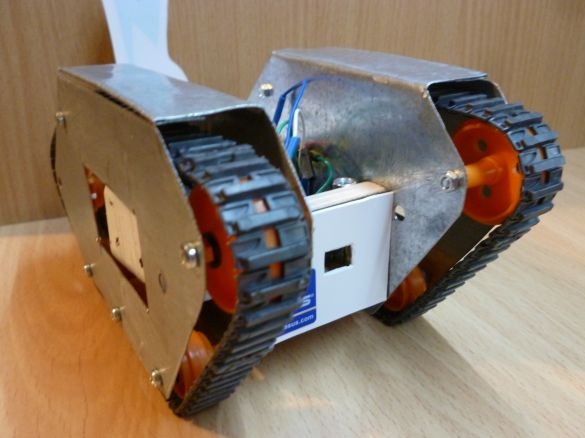

We take our base, on a double-sided tape we glue a board on it. The metal parts for the first scan need to be screwed onto small self-tapping screws to the base on the sides, bent outward. Be careful to screw it so that the extreme 6 mm hole is put on the output axis of the gearbox, the bottom of the part must be parallel to the base and symmetrical in relation to the second such part. The result should be:

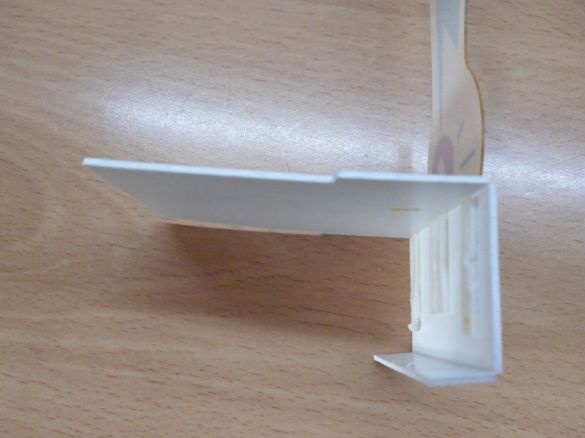

To give our homemade aesthetic look, add a couple of details. It's not obligatory. From white plastic, cut out a 110x55 mm rectangle and bend as shown in the photo. The tail is also optional, but I liked how it looks and shakes when moving:

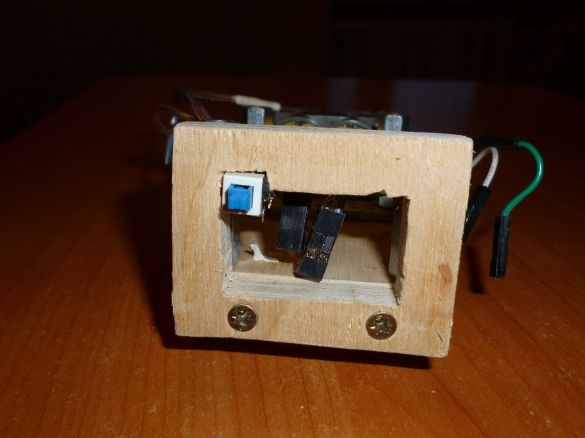

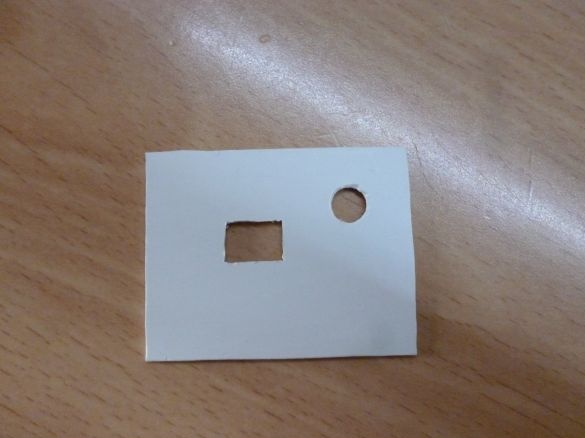

This cover covers the gearbox so that dirt does not get into it, and it makes so less noise. Next, we also cut a 52x41 mm rectangle from white plastic. We make holes for connecting the Arduino and the power button as in the photo:

Glue it all on a double-sided tape:

Sticker for beauty.

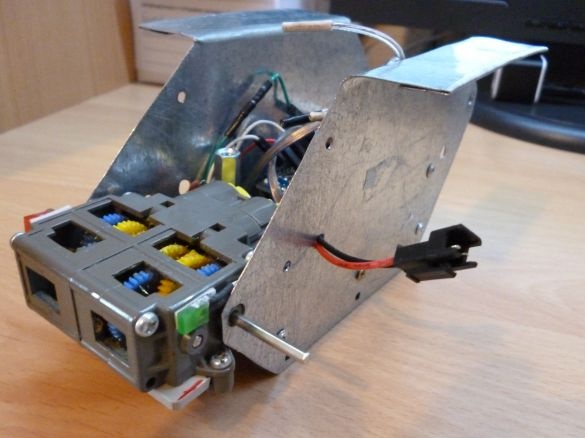

These two parts can be made from almost any material that is at hand. It can be thick cardboard (which can then be painted), fiberboard, thin plywood or a piece of plastic of any color. Do not forget about the batteries. Glue them on a double-sided tape on the right metal part of the base:

Step 5 Caterpillars.

Here we will need our second scan blanks. We insert bolts with a 3x20 semi-cylindrical head into the 3 mm hole. Put on the washers and tighten the nuts:

Washers must be worn before the rollers. I was not too lazy and ordered plastic washers. You can use ordinary metal, but then our tracks are very noisy. After the rollers, we tighten the nuts without tightening, so that the rollers rotate freely.

We put rubber tracks on the rollers. We put the plate along with the rollers on the base, making sure that the bolts fall into the holes. And tighten the nuts. We get an almost finished tracked chassis:

Step 6 firmware.

In my opinion, it is most convenient to write firmware in the Arduino IDE. The chassis we assembled is universal and firmware is required depending on the specific purpose. You can connect a Bluetooth module and use your phone or computer to control. It is also possible to connect an IR sensor and use an IR remote control. Another control option is the use of a 433 MHz module to communicate with the remote control. Based on the chassis, it is possible to make a robot following the line or any other autonomous one. I post firmware for Bluetooth, 433 MHz and IR.