If you want to make your own car absolutely unique, then various details can be made do it yourself. For example, this time we will consider how to make a bumper for a car from scratch foam or polystyrene from scratch, or maybe using just two of these materials. Theoretically, you can create any bumper design, but how it turns out, it all depends on the experience of the master.

Let's consider in more detail all the ways to create a bumper from scratch.

Materials and tools for homemade

Depending on the chosen method, mounting foam or polystyrene will be needed, or maybe even all at once. If polystyrene will be used, then “liquid nails” will also be needed for gluing.

Whatever method of the above listed would be chosen, in the end they will still be needed:

- sandpaper of various grain sizes;

- putty;

- technical clay;

- fiberglass;

- By itself, paint with all the tools for applying it;

- a cutting tool for working with foam or foam;

- in some cases, you need welding, grinder, etc.

How to make a foam bumper:

This method can be considered one of the most difficult, since the bumper is created from scratch from the frozen mass of foam. Here you will need high precision and skillful hands.

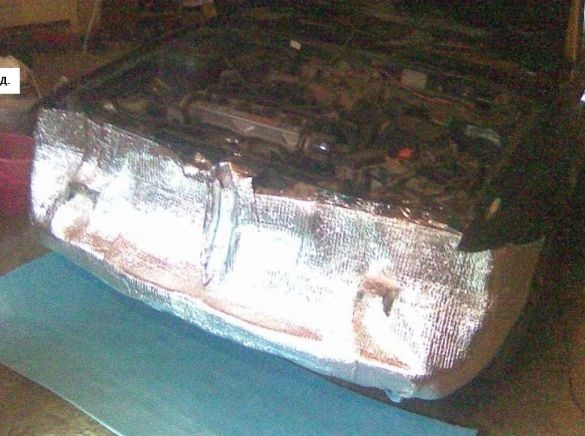

Step one. Surface preparation

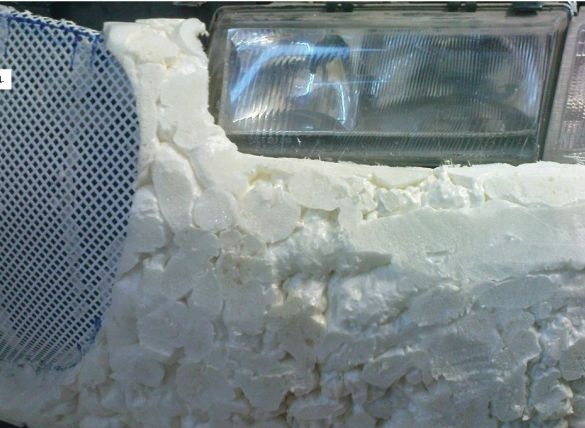

First you need to prepare the body for applying foam. It must be washed and degreased, otherwise the foam will stick badly. Due to the fact that the foam is aggressive against metal, all equipment must be removed, and open areas, if necessary, covered with a penofol.

Step Two Foam application

In total, to create a bumper, you need about 4 ex-foam cylinders. It must be applied evenly and abundantly. The foam should be allowed to dry for at least 2 days, since such a mass will dry for a long time.

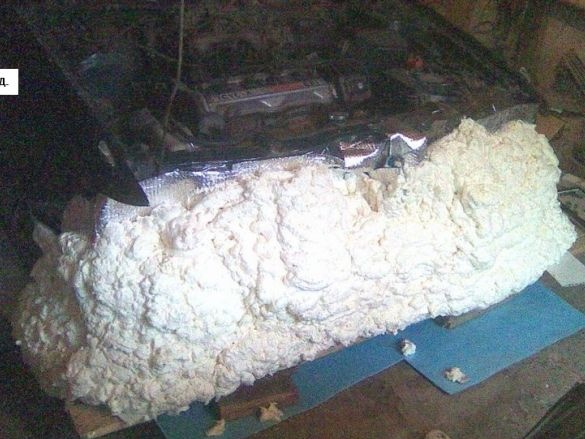

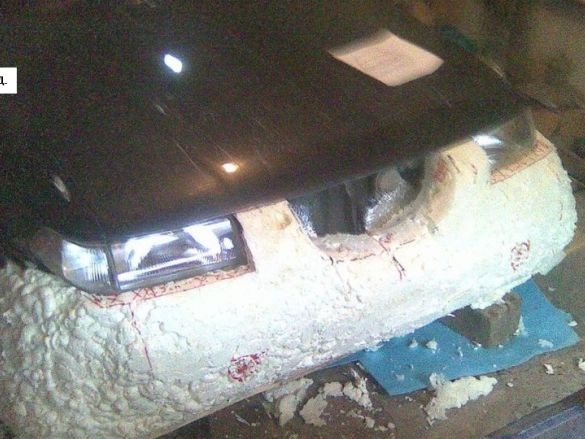

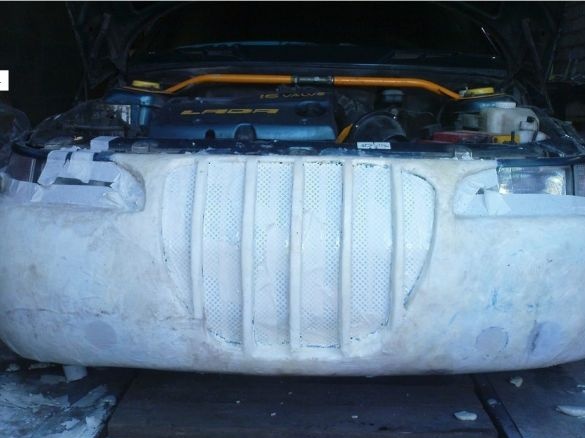

Step Three Design and creation of a bumper on it

Having created the desired project, the bumper is now cut from scratch from all this mass. In the process, about two balloons of foam will be needed to fill the voids. When the bumper is completely cut out, resin and glass wool come into play, they will form a durable outer bumper coating. According to the author, fiberglass 300 is best suited for such purposes. In total, to create a bumper, you will need to make 4-5 layers of glass mat.

That's all, go to the next method.

How to make a foam bumper:

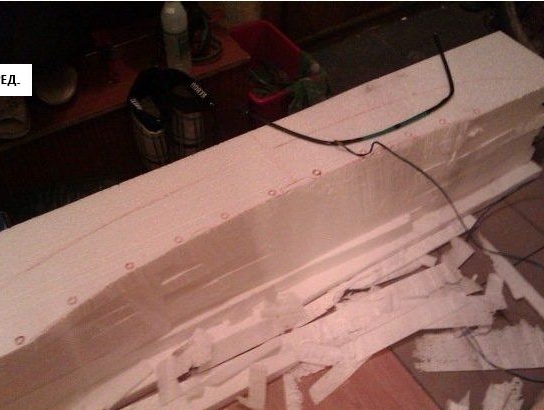

Step one. Form creation

Using this technique, creating a bumper is a little easier, since you do not need to apply layers of foam. The form is created from pieces of polystyrene foam, which are glued together with the help of "liquid nails". A total of 8 foam sheets were used in this example.

Step Two Sketch

A sketch of the new bumper can be done on paper while the glue dries. Now that the glue has dried, you can arm yourself with a knife with a marker and start creating new outlines of the bumper. Here the cutting process will be a little more complicated than in the case of foam. This is especially true for those places where the frozen glue is.

Step Three Outdoor coating

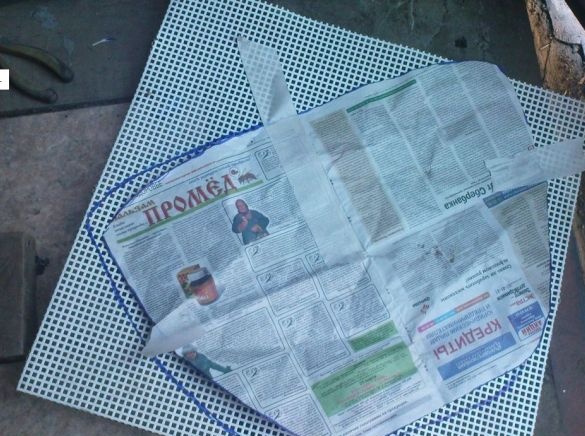

Polyester resin must not be applied to the foam since it will corrode it. In this regard, first you need to put on the surface of technical clay or several layers of putty. When everything is dry, you will need to work with fine-grained sandpaper. Well, after that you can apply fiberglass and resin, as in the previous method. If there is no money for glass wool, you can use a newspaper, a bumper is glued to it, and another layer of putty is applied on top.

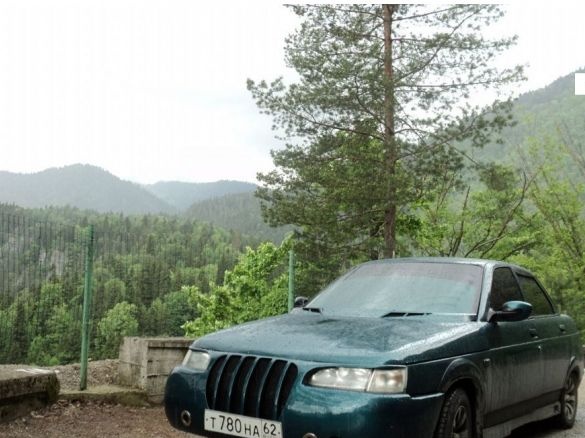

How to make a foam and foam bumper

With this approach, you can make a fashionable bumper. The process itself does not differ from the above. As a result, in the photo you can see the bumper, consisting of three layers of fiberglass 300.

Modification of the existing bumper

This method is the simplest and least costly, as the basis is the existing bumper.

Step one. Foam preparation and application

First, the foam application area must be thoroughly washed and sanded so that the foam adheres well. If the bumper has cracks and other defects, it is not scary. If necessary, damaged pieces can be removed altogether.

Then you can apply foam, it is important not to forget to create a radiator grill, otherwise the engine will not be able to cool. All those places that are responsible for ventilation and which do not want to be dirty should be closed.

Step Two Create a form

Now that the foam has dried, you need to create a bumper shape, a knife is used for this. Coarse edges need to be ground with sandpaper.

Final stage

Well, then, as in the above methods, resin and fiberglass come to the rescue. After applying the required number of layers, the surface is carefully treated with sandpaper. The surface should be perfectly flat. Then a putty top coat is applied, sanded, primed and painted.

In such a simple way, you can create a unique bumper for your car. Materials are available, relatively inexpensive, and the process is fascinating and fruitful. But you should not lower the bumper too low, otherwise it will quickly tear off on bad roads.