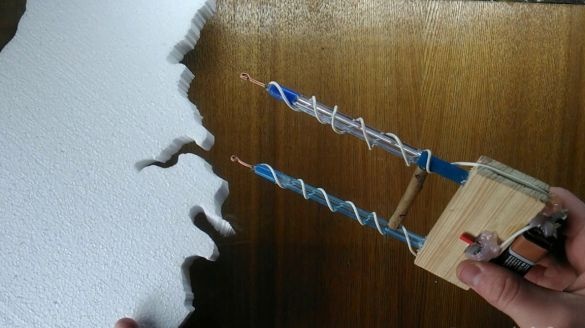

Hello everyone, dear friends, today I will show you a wonderful idea on how to make a portable nichrome cutter for cutting foam. This cutter is easy to use and does not require an electrical outlet. With this cutter, you can cut out various letters and figures on polystyrene foam.

Necessary materials:

- bar

- two handles

- nichrome wire

- copper wire

- crown

- switch

- connector for crown

- wires

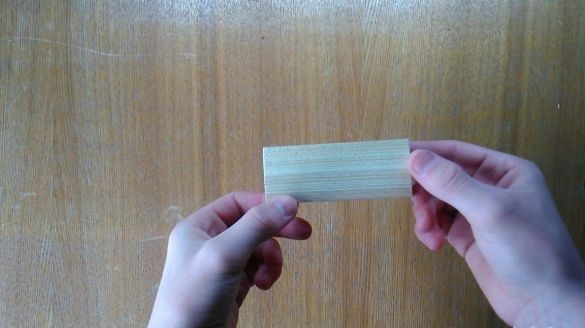

Step 1: Take a small bar measuring 100 * 50 * 20 mm. Then we drill two identical deaf holes in it to fix the tubes from the handle in them. Using the file, we make small grooves to insert wires into them.

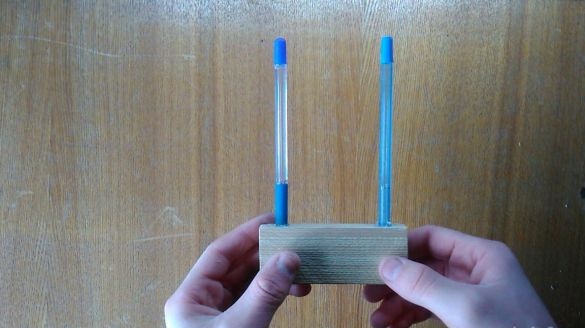

Step 2: Then, using the glue gun, glue the tubes, as shown in the photo.

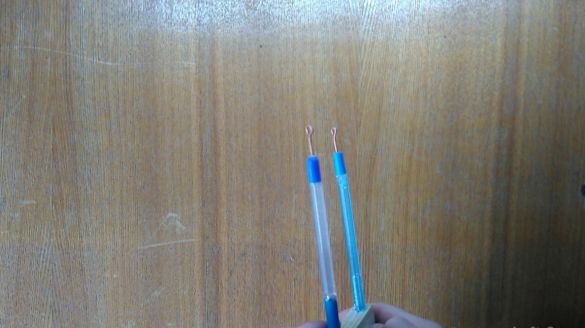

Step 3: Take two small pieces of copper wire and make small “ears” at their ends. And glue them to the caps of the handle.

Step 4: Connect electronics

Step 5: Take the nichrome wire, and attach it to the "ears". You can take nichrome wire: in a boiler, in a hair dryer, in an old soldering iron (I took from it). To pull the wire I put a small spacer from a piece of branch. We insert the crown, and you can cut !!!