Dear visitors of the site, from the material submitted by the author, you will learn how

do it yourself It is possible to make a CNC milling machine for wood processing.

It is no longer surprising that the guys assemble such machines on their own, practically from what they have at hand, among the masters already gained good experience in this direction, which the masters share with each other.

With the development of technology, at the human production, mechanisms were first replaced, then machines, today robotics and computers, which gives people high quality products, and most importantly for the manufacturer, this is a minimum of marriage, as well

robot will not go on sick leave))

Let’s look at how all the same, our author managed to create a CNC machine and what did he need for this?

Materials1. aluminum (scrap)

2. stepper motor

3. milling cutter

4. flexible hose

5. shaft

6. bearing

7. wire

8. computer (old)

9. foam

10. land

11. plywood

12. countersunk furniture nuts

13 syringe

14. engine oil

15. stud

Tool1. lathe

2. blowtorch

3. crucible

4. non-ferrous metal smelting furnace

5. polystyrene cutting machine

6. emery

7. tap

8. hacksaw

9. file

10. vernier caliper

11. drilling machine

12. jigsaw

13. ruler

15. set of wrenches

16. hammer

17. screwdriver

The process of creating a CNC milling machine with your own hands. And so, let's take a look at the beginning, which actually means CNC, but everything is extremely simple - this is a numerical program control. The very first numerically controlled machine was developed and patented in 1804, and it was at the beginning of the 19th century)) The machine was located at a weaving factory and several positions of the mechanism were encoded on punch cards, thereby raising or lowering the shuttle could make programming simple patterns.

Today, mankind has taken a very far step in the field of science and technology, computers have tightly entered our lives, in fact, what can I say if the CNC machines are already assembled independently from available means on the knee))

To create the machine, the author needed quite a lot of aluminum scrap, which he melted in an impromptu furnace, from a blowtorch and several ceramic bricks.

The author gained the first experience in casting and smelting aluminum during the manufacture of the machine; molds were made for casting the bearings of linear bearings.

Thomas is flooded and cools.

Here is such a blank.

The master transfers the resulting blank to the workshop.

Everything is prepared and cast for subsequent processing on a lathe.

Directly working on a lathe.

In the course of work on the casting and smelting of metal, the author came to the conclusion that a primitive but metal furnace is required.

With metal casting, it’s finished so far, then the master whipped up a polystyrene cutting machine.

Outlined template.

Cut the foam blanks, it will serve

model during subsequent casting of aluminum.

The model is coated with a building mixture.

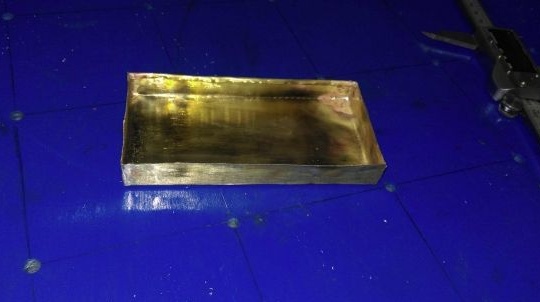

Then again cast aluminum, but already in earthen form.

The first pancake is lumpy, as expected)

Then everything went like clockwork.

Another batch of forms is being prepared.

Cast and already on the table in the workshop.

Drawing and cutting the template again.

The author drills the cast workpiece in the intended places.

Procedure with portal racks.

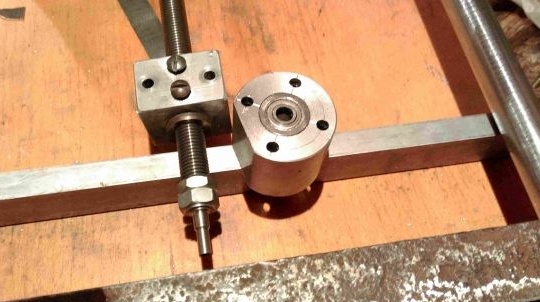

The master made linear bearings from the pins of a GAZ-53 automobile.

Guides on the axis X = 25 mm, and on the axis Y = 20 mm.

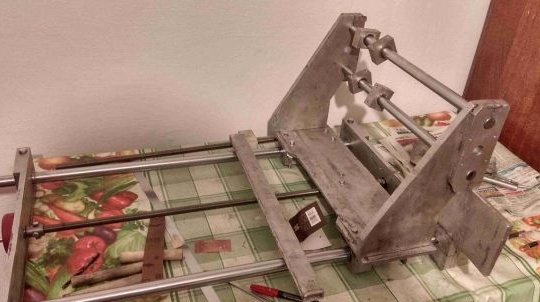

Assembly of the base of the machine.

Groove of running ends on a lathe.

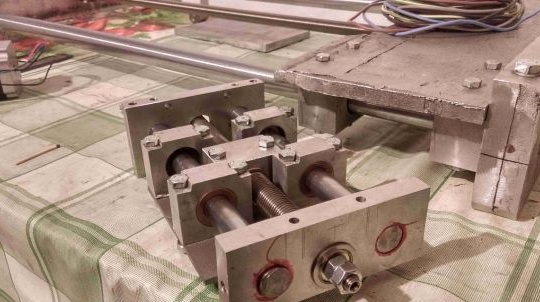

Production of a running nut with clearance adjustment.

Trying on the Y axis.

Then there was trouble, a crack in the metal!

Complete collapse!

The author does not despair and casts the 2nd detail and again a crack, oh horror !!!

The master already wanted to spit on everything, but nevertheless he got together and rethought the situation and came to the conclusion that the shape of the part must be changed. So I did, now everything is fine))

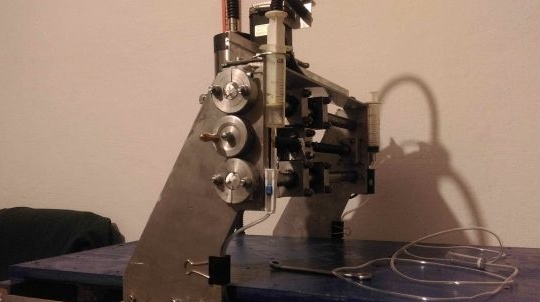

Refinement and assembly of nodes.

A stepper motor is installed.

And again a crack.

The part is re-melted and bored in a new way.

A temporary plywood table is fastened with screwed-in countersunk nuts for fastening parts.

The brains of the machine and all related

electronics.

Spindle cut out.

The system unit is assembled.

Further, the author creates a lubrication system.

Cranes are made of caprolon.

With the help of a crane, the oil flow is regulated, the master has 1 drop in 3 minutes.

The master installed a wire in the hoses to keep it from bending.

A pan was made to collect the oil.

Test run.

The first work on the machine)

The author did it! Hurrah!!! Now he has his own CNC milling machine. As you can see, if you want everything, just a simple person can do it; you just want to) A lot of interesting and beautiful carved things can be done on this machine, imagination is limited only by the size of the machine) In the future, the author is going to create a machine much more, for serious work, there is already experience)

This concludes the article. Thank you very much for your attention!

Come visit often, do not miss the latest in the world of homemade goods!

This article is for informational purposes only!