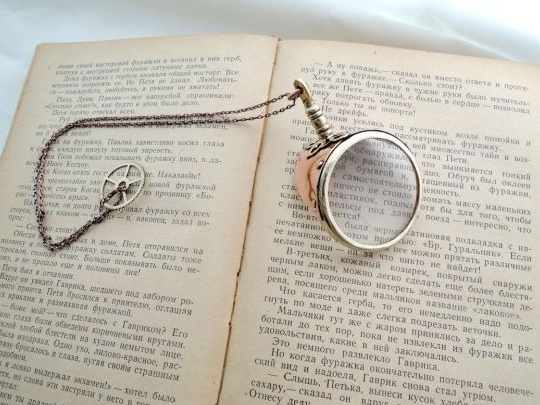

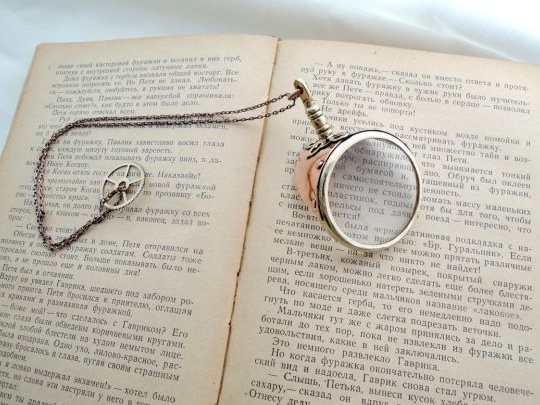

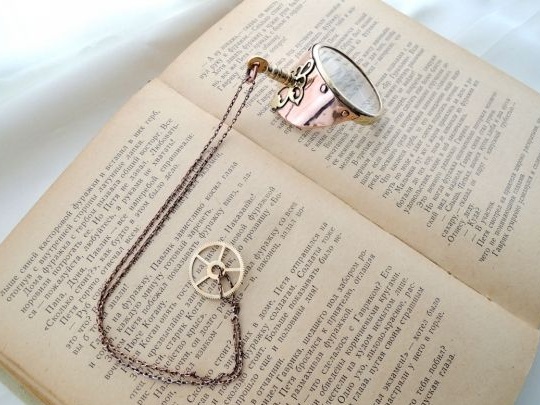

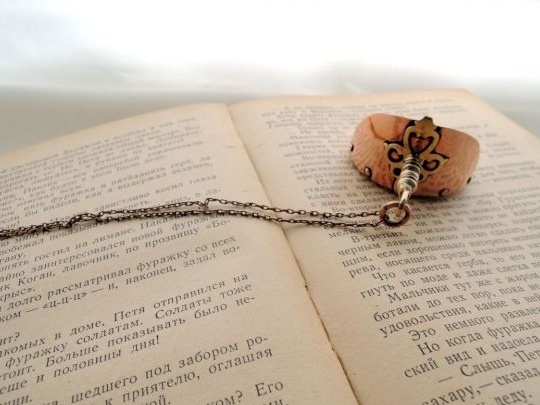

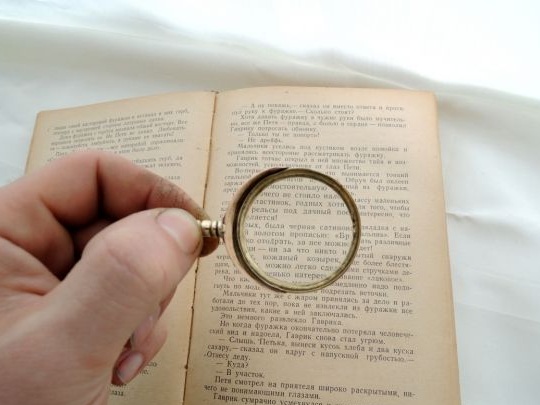

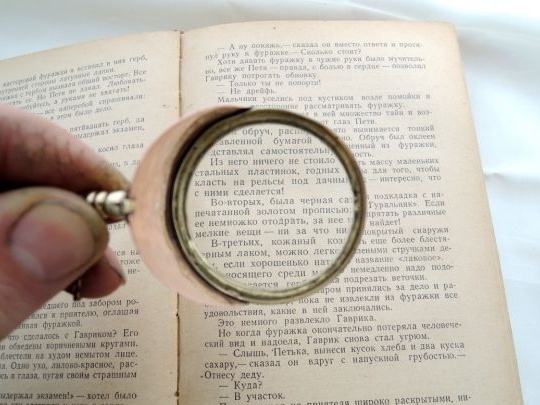

Translated from Latin, monocle means (mono) -one, (orulus) -eye, one of the optical devices for correcting or improving vision. As a rule, it consists of one lens in a frame, with an attached chain or a cord, for attaching a jacket, buttons to a lapel, in order to avoid loss.

The author took the 19th century monocle as the basis and, on its basis, made his own directly in the stylesteampunk"with a cooler. To create the device, the master used copper and brass as always.

And so, let's look at how the author managed to create such a rare thing in our time? And also find out what exactly is required for this?

Materials

1. brass sheet

2. copper sheet

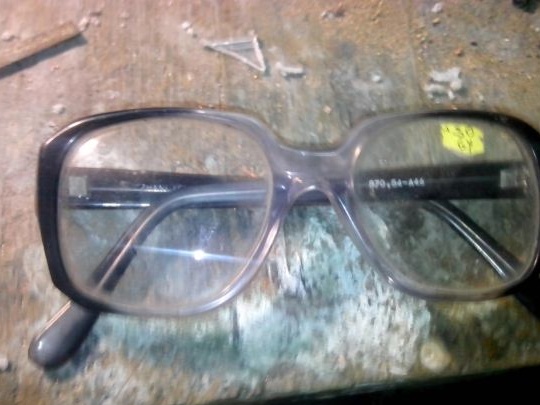

3. Glass from glasses

4. brass chain

5. hand (from old watches)

6. gear

7. glue (for glass)

8. brass wire

9. pin contact

10. refractory solder

Instruments

1. drill

2. metal scissors

3. file

4. file

5. sandpaper

6. hammer

7. burner

8. velvet

9. disc

10. vernier caliper

The process of creating a monocle do it yourself.

And so, you should start with the history of this fixtures to improve and correct vision, the monocle was first used in the 14th century, the eyepiece had a rim and a long pen, which was held in the hand and, when reading, was pointed at the text or pressed to the eye socket. In the 16th century, the design was improved and the monocle was in the usual frame, and to hold it while reading it was simply pinched in the eye socket by the muscular parts of the face.

As a model for his work, the author took a 19th century monocle, here it is presented in the photo.

This concludes the article. Thank you very much for your attention!

Come visit often, do not miss the latest in the world of homemade goods!

This article is for informational purposes only!