Hello to all lovers homemade. Good lighting for video shooting is the key to success, but even with a good light source, such as a spotlight, it is not always possible to conveniently, and most importantly, correctly direct the light, since there is no way to do this fixtures. Therefore, in this article I will tell how the author made a tripod for a searchlight, which will also save your money. You don’t need a lot of money to create, we still have a budget option, so all the details can be purchased for a purely symbolic amount.

In order to make a homemade tripod for a searchlight you will need:

* Polypropylene pipes

* Glue, the well-known "second" will fit perfectly

* Clip

* Tees for pipes

* Corners

* Hacksaw

* Spotlight for self-test

That's all that is needed for further production, so that from the little things you can collect a useful thing

Step one.

First of all, you need to decide on the dimensions of the future tripod, namely the height and width of the legs, which in turn directly affects the stability of the structure and varies depending on the mass of the camera or video camera used.

Step Two

Once you have decided on the dimensions, you can go directly to the manufacture. At this stage, after all, the hacksaw will be metal. Why exactly metal, you ask, and everything is simple, since the hacksaw blade has small teeth, then it will leave less scoring and the clarity of the cut will be better compared to a hacksaw with a large tooth. Saw off the pipes of the required length with a hacksaw, after which it is better to sand the place of the saw, eliminating bumps and pieces of plastic.

Step Three

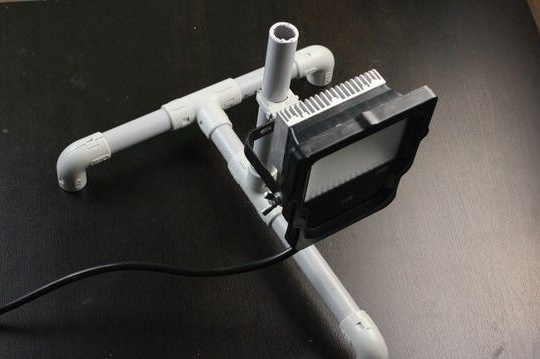

Now we need to fasten the parts together, first we use the tees and connect the pipes so that the base of the tripod turns out, and so that the pipes do not separate for reliability by a drop of glue “second”, we glue the joints in all subsequent assembly steps. In fact, it should look something like this.

Then we attach three corners that will act as legs.

The legs are ready, it’s time to fix the main pipe on which the spotlight will be held, also choose the length depending on your needs, for shooting at remote distances a pipe within 1-1.5 meters is suitable for full growth.

Step Four

We turn to the hero of the occasion, namely the spotlight. It will be most convenient to attach it to this pipe with a clip, in which there is already a hole. We connect the fastening of the spotlight to the clip with a bolt.

We check how the whole structure is held on the pipe. For a spotlight of such sizes, the clip holds well enough, but if you decide to hang something larger, the fasteners can be strengthened with another clip.

On this, the tripod for the spotlight is completely ready, all assembly steps do not require much effort, as well as time to manufacture.

Thank you all for your attention.