Dear visitors of the site, from the material presented by the author, you will learn how to make a "skeleton watch" yourself. And what is this watch? Yes, everything is extremely simple - it is a watch without a dial and all the insides of the mechanism are clearly visible through the glass, that is, the skeleton, hence the name is “skeleton”.

Our author works mainly in the direction of "

steampunk", a very interesting topic, and most importantly, a lot of technological subtleties of working with metal can be found out. The main part of the details is machined on a lathe, then soldering with silver or POS. Accuracy and rigorous calculation are always observed.

And so, let's look at how the master created his watch and what exactly did he need for this?

Materials1. brass blank

2. Lightning watch

3. 5 mm plexiglass

4. glass

5. genuine leather

6. silk thread

7. buckle

8. copper bar

9. copper sheet 1 mm

10. solder (silver)

11. epoxy resin

Instruments1. lathe

2. vernier caliper

3. burner

4. ammonia bath

5. sandpaper

6. drilling machine

7. file

8. glass cutter

How to create a "skeleton watch" do it yourself, detailed description and photo.And so, according to the author, to create such an extraordinary watch, he used the old but still Soviet-made “Lightning” clock as a basis for which the clockwork was removed, then a new case made of brass blank is grinded on a lathe. The master also made minor changes to the design, namely, he redid the place of installation of the crown from 3 o’clock to 4 o’clock, which added to the watch’s uniqueness and unusualness, which is pretty much appreciated nowadays.

The mechanism is retrieved.

Luminescent paint glowing in the dark, namely its solution in epoxy, was applied to the case and arrows.

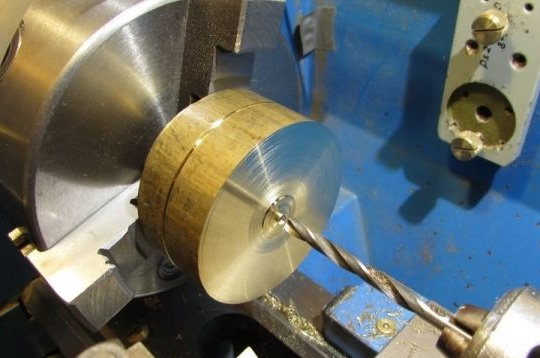

Next, the master proceeds to the manufacture of the case, for which a brass blank is taken and charged into the chuck of the lathe.

The inside is being pierced.

After it is cut off.

Glass is cut using a glass cutter.

Glass is tried on, after which it will be inserted into the grooved groove and glued to the epoxy resin.

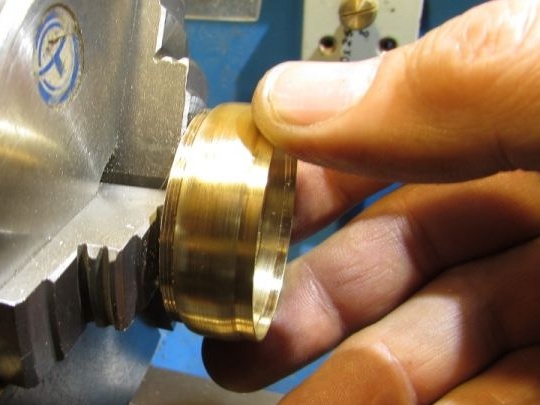

Then, on the machine, the author grinds the back cover with M 7 thread.

The screwing control of two parts is carried out.

That's actually such a case turned out.

Trying on a mechanism.

Further, 5 mm plexiglass is used to make glass for the back cover, because it will also be transparent.

Boring is also done on a lathe, with the inside being also selected with a cutter.

Preliminary fitting.

This is how the back cover will look, through which gears and springs of the clock mechanism will also be visible (to increase the entourage)))

Then the ears are soldered to the case for attaching the watch strap made of genuine leather.

The ears are cut in the form conceived by the author.

The master, as they said, set his head in position for 4 hours.

Then the case is placed in an ammonia bath for the acquisition of patina.

That's what happens after the bathhouse.

Heats up with a burner.

And such a beauty is obtained.

The mechanism is inserted.

All watches are assembled and work great.

The strap was made of genuine leather.

So the belt looks from the back, where the technological hole is specially cut and again the whole watch mechanism is perfectly visible.

These are such wonderful and unique watches that our author made, and uniqueness in our difficult time is very important, and again, handmade work that is pretty well priced. Such a watch will surprise even the most capricious fashionistas and women of fashion.

This concludes the article. Thank you very much for your attention!

Visit us more often, do not miss new items in the world of homemade goods!

This article is for informational purposes only!