In this article, the author will share with us the secret of how to make a flip board for acrobatic exercises. But first, let's figure out what it is and what it serves. This is what reference books say.

TIPBOARD - circus projectile in jump acrobatics rooms; a board 2-3 m long made of durable elastic battens, mounted in the middle on a metal stand (gantry) 40-50 cm high and swinging freely on it. The upper acrobat stands on the lowered edge of the flip board, and the partner (slugger) jumps to the raised opposite end of the blackboard (“chops”). The thrown upper one performs somersaults and other acrobatic and gymnastic exercises in the air and comes to the lower shoulders, a “column” of several people, etc. The principle of the action of the throwing board is borrowed from old folk games. As a special acrobatic shell introduced at the beginning of the 20th century.

As you can see, from the description, the throwing board is used by acrobats in a circus or a gym. Therefore, in order to avoid accidents, the author warns: Classes on the board should be conducted in compliance with safety measures and under the guidance of an experienced teacher.

Tools and materials:

-Boards:

-Pipe profile;

-Metal strip;

- Bearing bearings;

-Shaft;

-Bearings;

-Bolts, nuts;

-Welding machine;

-USHMka;

-Drilling machine;

-Miter saw;

-Electroplane;

-Roulette;

- Clamps;

-Hammer;

-Gon;

After all the material and tools are assembled, you can proceed to the next step. The author accompanied each step with a detailed video.

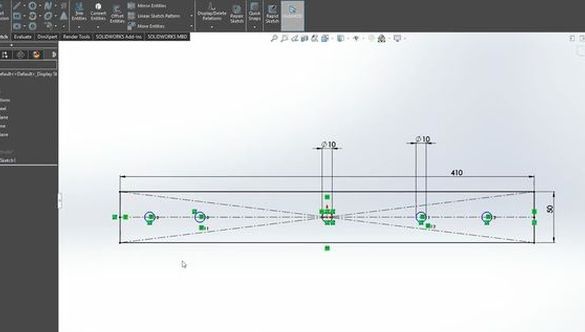

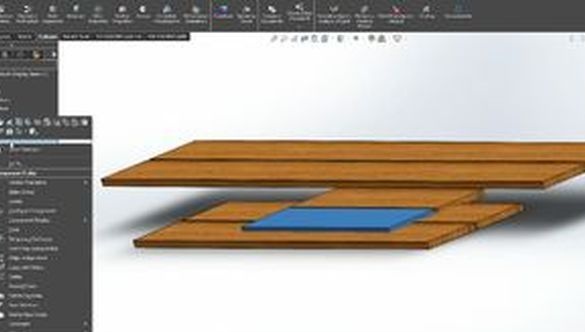

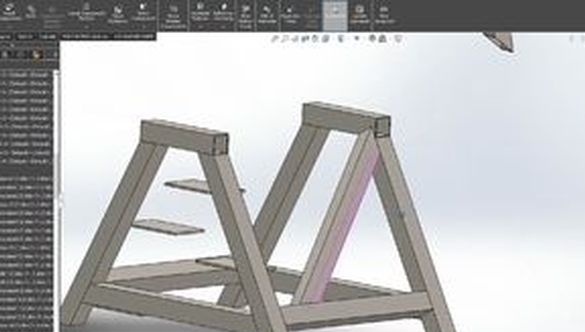

Step One: Design

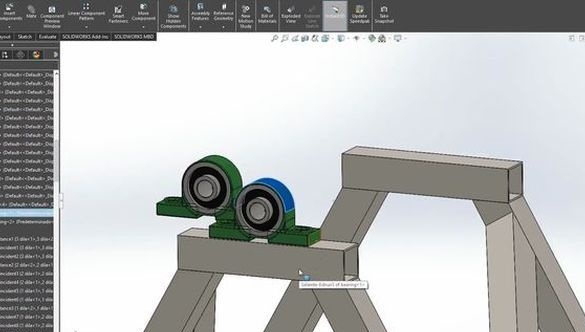

First, the author makes a 3Dmodeling products. To make the flip board, larch boards of different lengths, in three layers, will be used. From below, the board will be attached to the shaft and through the supports to the machine. The machine will be made of 40 * 40 profile pipe.

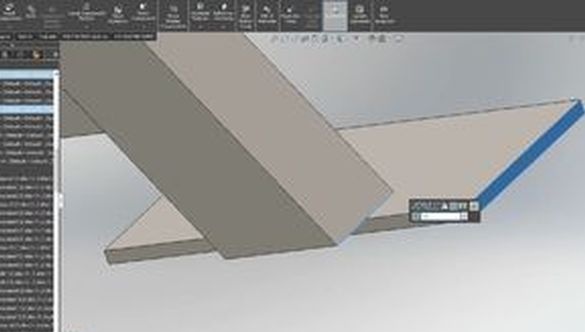

Step Two: Making a Machine

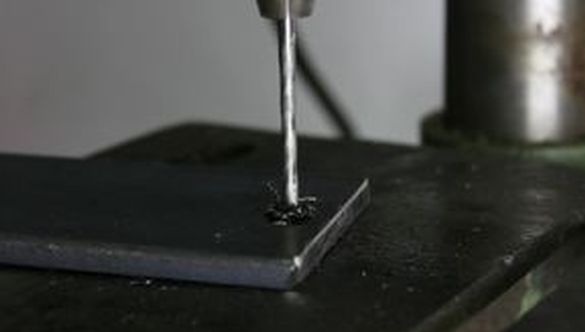

Harvests the desired length profile. Welds the machine and cleans the seams. Drills holes and secures bearings with bearings installed in them. Sets the shaft.

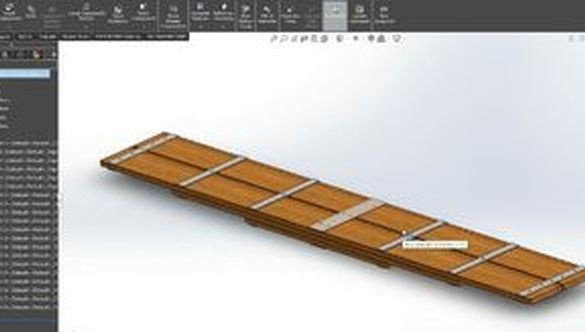

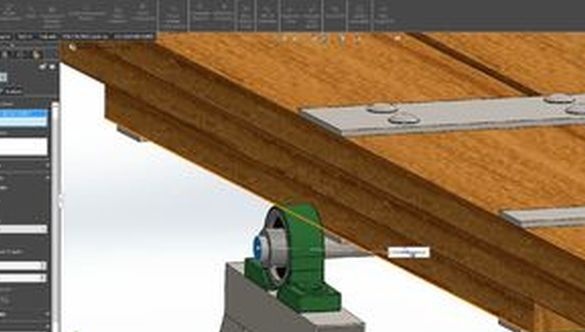

Step Three: Board Making

She cuts six boards two by 1 meter, two by 2 m, two by 3 m (later meter boards were removed). The width of the boards is 20 cm.Plane processes the ends, polishes. Using a strip and bolts fastens the boards together. A shaft is welded to the strip and secured in the center of the bottom board.

The flip board is ready. It remains to test.

During the test, the author removed one set of boards from the bottom, this improved the technical characteristics of the folding board.