Dear site visitors, from the master class presented by the author, you will learn how to make a cyclone filter from old and unnecessary plastic buckets

do it yourself. This type of filter is very popular with joiners and furniture makers, because it is very easy to manufacture and unpretentious in operation.

Each artisan person who is engaged or keen on carpentry is simply obliged to have such a filter in his workshop.

So our author is engaged in carpentry, so as not to overgrow with sawdust and shavings in his workshop, he decided to keep his workplace clean, for which he made a cyclone from an old plastic barrel and bucket, as well as a vacuum cleaner that drives this filter.

And so, let's take a closer look at how the master assembled the cyclone filter and what exactly was needed for this?

Materials1. plastic barrel 25-30 l

2. Chipboard

3. hot glue

4. PVC pipe

5. silicone sealant

6. self-tapping screw

7. bolt

8. nut

9. corrugated hose

10. vacuum cleaner

11. adhesive tape

12. electrical tape

Instruments1. milling cutter

2. drill

3. jigsaw

4. Festulovskaya roulette

5. thermal gun

6. stationery knife

7. 50 mm core drill

8. pencil

9. screwdriver

10. pliers

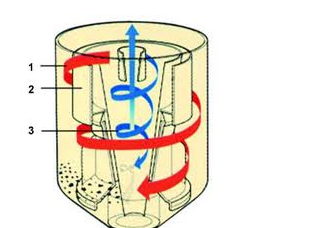

The process of creating a cyclone filter with your own hands.And so, first you still need to figure out how this miracle machine still works? There is nothing special here, 2 containers are taken, one for a cyclone and another for collecting garbage and sawdust (hopper) Inside the first container there is a cone that prevents dust from rising upwards, and 2 pipes are located at the entrance to the side of the container at an angle of 45 degrees, that is, when sucking in dust and sawdust falling into the filter, they rush into a swirl along the vessel wall, and purified air is supplied through a straight pipe located in the upper part of the lid. To make it more clear, the author provided a figurative diagram of the filter, we look.

Further, the entire apparatus is assembled.

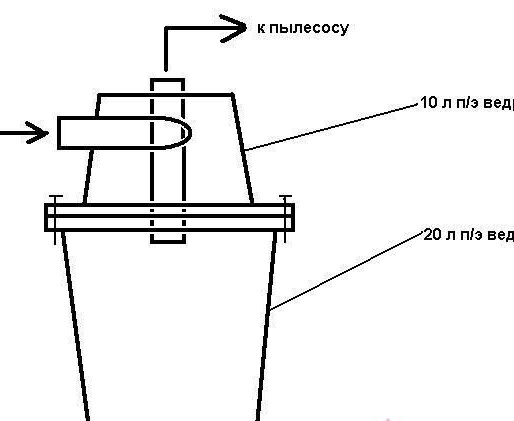

And a simple drawing for greater clarity.

In general, I think the principle of operation of the cyclone filter is clear, now we should go directly to the process of manufacturing the apparatus itself.

As mentioned above, the master used 2 containers - this is a plastic barrel with a volume of 25-30 liters, it will serve as a receiving hopper for sawdust, and for a cyclone a 10 liter bucket, also made of plastic, was used. Here they are.

Further, the author began to manufacture covers for buckets, because there were no relatives, and plastic covers are unreliable. The material used was chipboard. Using a Fistula roulette, the diameter of the bucket was measured and the radius was calculated, that is, the diameter is divided by 2 and the radius is obtained, a circle is drawn on the board.

It is sawn out using an electric jigsaw, with an overflow of 2-3 mm prozapas.

The resulting lid must then be cut off on a milling machine, for which the author did a simple

device from a laminate.

Processes edges and creates a groove.

A groove is necessary so that the lid fits very tightly and tightly, because the filter should in no case suck in air through any slots.

Everything went perfectly.

The cover for the cyclone itself is cut in the same way.

The author puts a silicone sealant on a bucket.

The lid also fit very well.

Then it is necessary to cut a large hole in the hopper lid, which will connect the 2nd containers into one.

On the inside of the lid you need to grind the landing groove for installing the bucket.

The author performs the work carefully and without rushing.

Here is the result.

Check, everything went well.

Next, the master cuts out the bottom of the bucket.

A cone is made from a sawn bottom, cut out a sector and glued with PVC glue.

He pulled it with clamps and left to dry, but in the end it turned out so that the glue did not stick together and had to be redone.

The landing groove on the hopper lid is filled with hot-melt adhesive, but you need to work faster, the master hesitated a little and the bucket got up a little crooked, because the glue was already hardening.

Bucket installed.

Excess glue is cut off with a clerical knife.

Silicone sealant is also desirable to put on hot melt, so that in the process it does not fly off.

In the center of the lid, a hole is drilled with a crown using a drill.

A piece of PVC pipe 12 cm long is inserted into the resulting hole with a diameter of 50 mm, it is also advisable to process the seat with glue or sealant.

Installed and sealed.

At the bottom of the tube protrudes 5 cm.

Further, a hole is drilled in the side of the filter housing with the same crown.

A 45 degree elbow is inserted.

Fastens to a wall of a bucket by means of a bolt and a nut.

The junction is treated with hot-melt adhesive (can be silicone sealant).

And now, the cone, as was said the first stage of its creation, was unsuccessful and the author made fastening with bolts and nuts.

Set and secured in the bucket cavity with the tip of the cone up.

Put the cover on the cyclone body.

And here is the cyclone assembly.

The lid is placed very tightly, but nevertheless the author additionally secured it to several screws (just in case)))

Then the whole structure is assembled together.

Then the vacuum cleaner is connected through adapters and corrugated hoses, the master additionally wraps the connections with tape and electrical tape, so that there is complete sealing and the filter works flawlessly.

As you can see, the cyclone filter is quite simple to manufacture, the main thing would be desire))) A very useful device for the workshop of a professional and amateur carpentry.

This concludes the article. Thank you very much for your attention!

Come visit often, do not miss the latest in the world of homemade goods!

This article is for informational purposes only!