For the pump he needed: a CD-DVD drive, an old canister made of tin, two motors working from 12 volts, a button, a syringe, wires, 2 diodes and one brass plug from under a gas spray. From the drive, the author took only the bearing on the board and the axis.

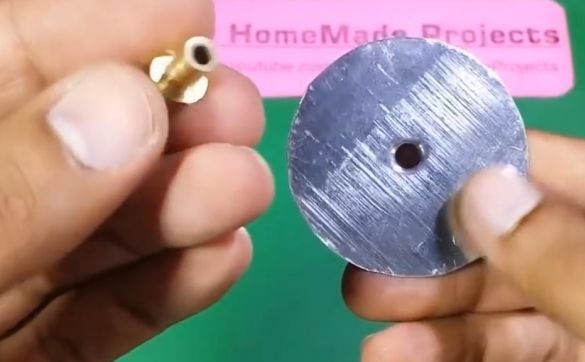

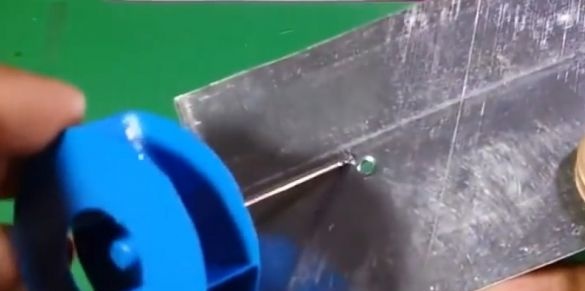

I drilled a hole in a brass plug, of a diameter so that it would fit tightly on the motor axis,

so he got a kind of sleeve.

Then he put this part on the motor,

connected it to a power source,

file, gave her the shape of a sleeve.

From the tin canister, the author cut two circles, (having previously marked the center on them

this size

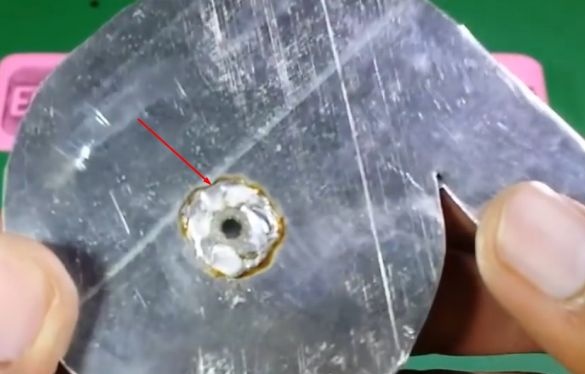

in one of them he made a hole in the center for a sleeve made earlier, and in the second a larger hole.

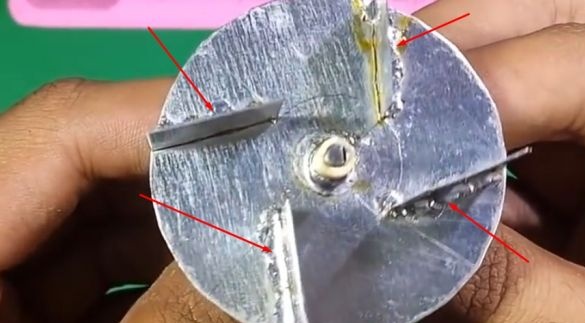

Author inserted sleeve

soldered it with tin.

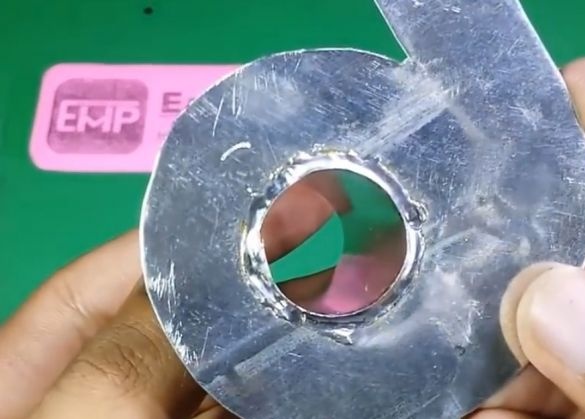

Then he cut out the plates from the canister too and soldered them,

Then he took the second circle and applied it from above, soldered from the inside to the plates.

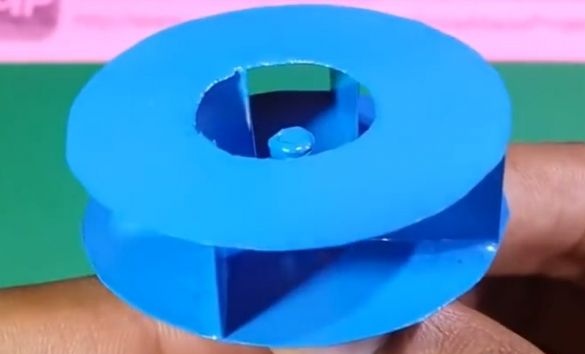

After which the author painted the construction.

Then he took another piece of tin and made a hole for the axle.

He took the marker and circled the structure

having drawn such a figure by hand.

The author carved two such snails.

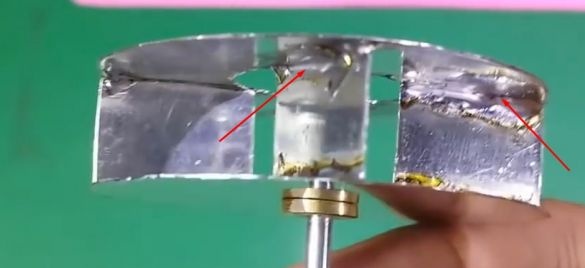

He put one of the snails on the axis of an already painted blank

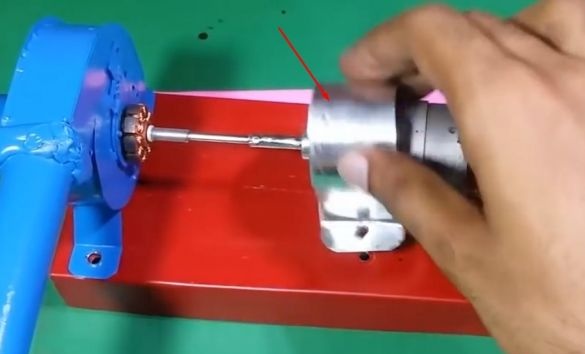

then put on top of the removed early bearing.

And soldered the board with the bearing to the cochlea on both sides.

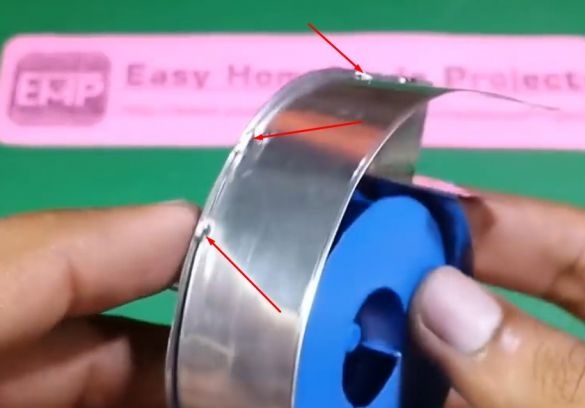

cut a strip of tin (size in the picture)

Wrapped a strip around the edge of the snail

and soldered from the beginning in several places

then completely disappeared,

and the edges on both sides.

Then he made such a pipe out of tin.

He inserted this tube into the second snail

and soldered.

He put it on top of the first one and soldered everything, cut out the legs for fastening and also soldered them.

Then he took a syringe and cut off the edges of it,

put it in the cochlea and glued it with hot glue,

so it looks from the back.

Then the author took the tin lid and proceeded to assemble the entire pump. Having attached all the details, he marked the places for fastening

in the marked places he made holes.

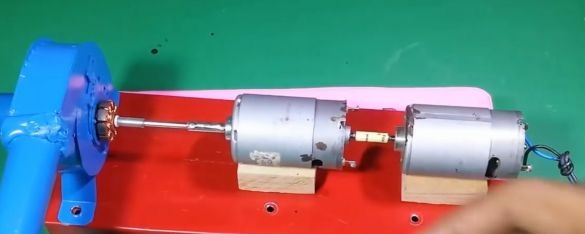

On the motor made a sleeve to connect it with a snail

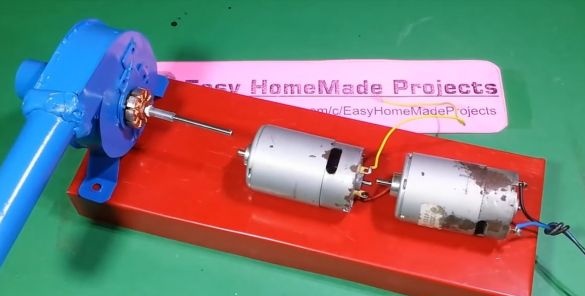

in order for all the details to be on the same level, the author put wooden substrates under the motors.

attached motors with clamps, and the snail just bolted.

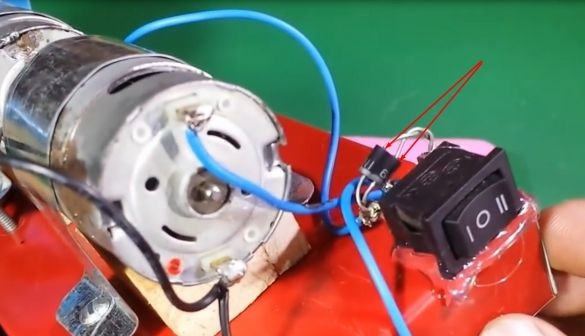

Connected the motor in parallel, soldering their ends to the button through diodes.

Well, the author has finished assembling the twin-engine pump.

[media = https: //www.youtube.com/watch? v = O-YbyvOZqDU]