For a craftsman, this stanochka is simply irreplaceable, because constantly something needs to be sharpened, sharpened). Buying a factory emery of good quality today will be a little expensive, and buying a cheap emery does not make sense, because its age is not long. The best option to do emery on your own, the tradition of using engines from washing machines to manufacture this machine, went back to the times of the USSR. Surely many still have such emery and work fine for several decades)

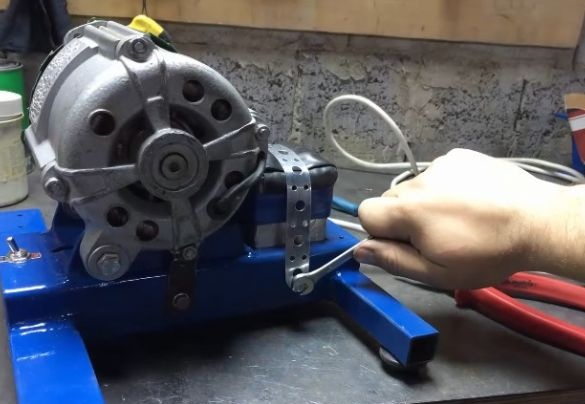

So our author decided to make his own grinder, and not spend money, moreover, in the garage stocks there was just an engine from an old washing machine.

And so, let's look at what exactly the master needed to assemble the emery?

Materials

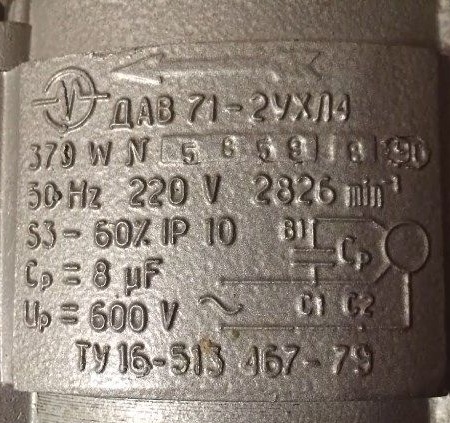

1. The engine from the washing machine. 220 at 2826 rpm 370 W

2.2 condensers with a capacity of 3 uF

3. grinding wheel

4. corner

5. professional square tube

6. rubber caps from antibiotic vials

7. switch (toggle switch)

8. wires

9. fork

10. galvanized sheet

11. flange for engine mounting

12. bolts, nuts, washers, grovers

13. paint

14. solder

15. electrical tape

Instruments

1. Bulgarian (angle grinder)

2. welding machine

3. drill

4. vise

5. metal ruler

6. marker

7. hammer

8. scissors for metal

9. screwdriver

10. wrench

11. soldering iron

12. pliers

13. knife

14. brush

15. tap

Step-by-step emery assembly instructions do it yourself.

As mentioned above, the best option is to use the engine from the washing machine, many probably have old washers that are still a pity to throw away or throw into scrap metal), so remove the motor and make a grinder) This is what the heart of the machine looks like.TTX must be indicated on the case, or on a plate screwed to it.

and the working surface of the table will be smooth.Additionally, the stand and the tabletop itself are cut.It is welded into a single design.It is cleared.Trial installation.So it should look like.With mounted grinding wheel.As you understand, the table can be moved and pushed back, after loosening the mount.After that, the threads necessary for the installation of rubber plugs are cut into the legs.Next, the master proceeds to painting the bed.In order not to stain the workbench with paint, it is necessary to put a newspaper under the object to be painted)Here they are rubber corks from bubbles.Screwed directly to the legs.This is what we get in the end.To turn on and off the emery, the master connects a switch.Connects wires.Attaches to the machine body.After that, the author makes a galvanized sheet protective cover for the washing machine motor housing, so that sparks and dross do not get through the holes.Outlines the center.Drills and tries on.The edges are cropped as in the photo.Bends and makes fastening.Here is such a casing.Installed and pulled with bolts.Next, the author collects an electric circuit, solders the contacts with a soldering iron.Fastens capacitors.And on the other hand, the same.After everything was done, the author took control photographs of the finished product.Thus, the master acquired another budget machine for his workshop and garage. such an emery can be made by a craftsman who will serve him for many years. Also, the design can be simplified and a frame made of timber and boards, so as not to use a welding machine, but as they say "This is a completely different story"

This concludes the article. Thank you very much for your attention!

Come visit often, do not miss the latest in the world of homemade goods!

This article is for informational purposes only!