Dear visitors of the site, from the material presented by the author, you will learn and learn how to build a carport for yourself. As you know, all kinds of precipitation and direct rays of the sun adversely affect the paintwork.

auto, also in our time, more frequent cases of hail and hurricane winds can also cause considerable damage. So, in order to protect his car from the vagaries of nature, our author decided to attach a small canopy for the iron horse to the wall of the house.

It was decided to take wood as the main material, because it is an environmentally friendly and kind material that does not rust and does not collect condensate, unlike metal. The master covered the roof with corrugated board. The timber was fastened to metal corners using self-tapping screws, so the design will be much more reliable. Also, with this design arrangement, material is saved due to the presence of the wall of the house.

And so, let's look at what the author specifically needed for the construction of the canopy.

Materials1. wooden beam

2. professional sheet

3. screws

4. anchor bolts

5. metal fasteners

6. silicone sealant

7. aluminum metal strip

8. tin 0.5-0.7 mm

9. 30 mm board

Instruments1. metal scissors

2. drill

3. punch

4. hacksaw

5. wrench

6. hammer

7. Bulgarian

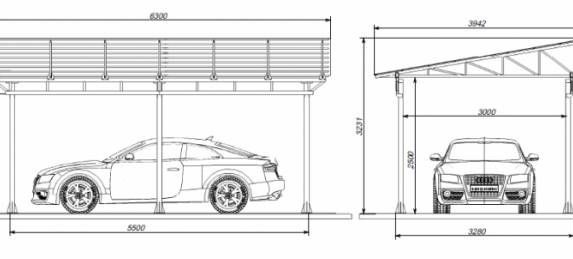

8. roulette

9. corner

10. level

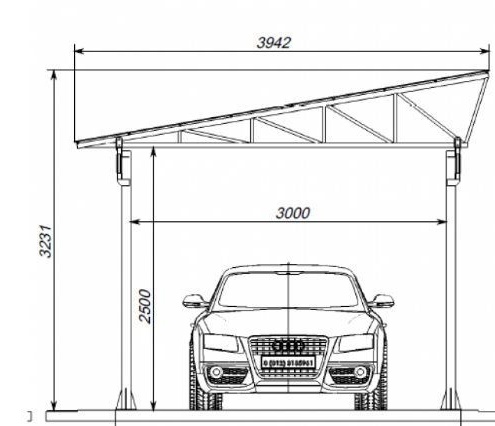

Step-by-step instructions for building carport do it yourself.As in any other construction, everything should begin with the preparation of estimates, development of drawings and diagrams in order to calculate all the nuances. Also, the first thing to do is to determine the place for the erection of the canopy. Firstly, there should be free access to it, it should not violate the architecture of the house and fit smoothly into it. The site should be concreted or paved with paving stones, the easiest way is to fill it with gravel and compact it. An even and firm ground is necessary so that the car does not push through the ground and the wheels are clean.

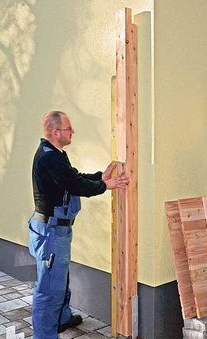

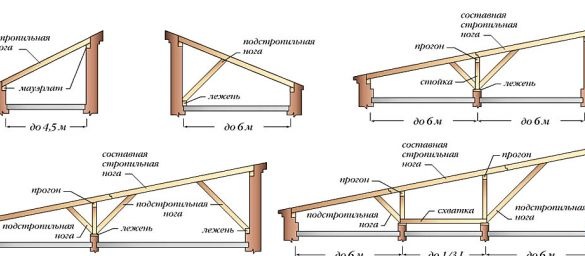

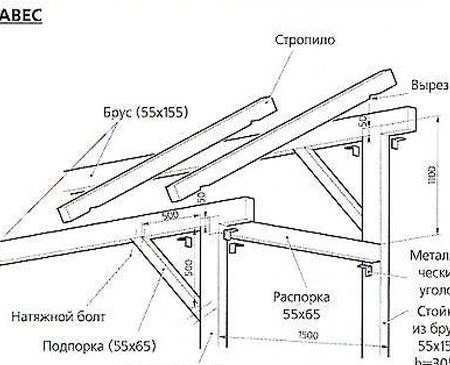

After all the preparations and reflection on the project, the author sets to work and he is faced with the task of erecting a frame from a timber with a ramp in one direction. First, the master takes the beam and fastens it to the wall of the house using anchor bolts and metal fasteners.

This is how it looks from the bottom

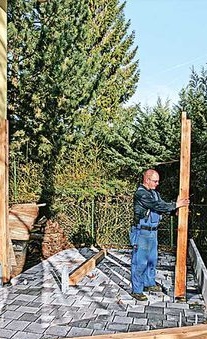

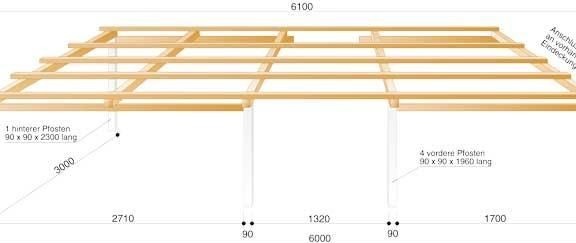

Next, the bars are installed in an upright position, attached to the paving stones on similar metal fasteners and anchor bolts.

And so along the entire length of the markup.

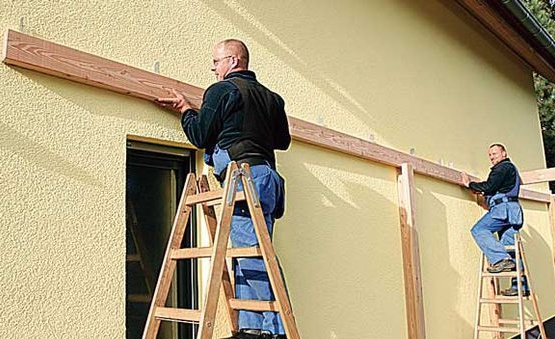

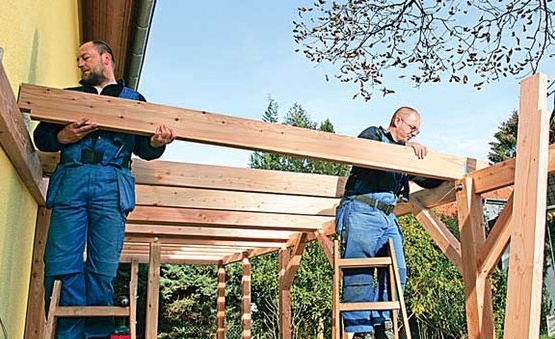

After the columns are fixed, the author proceeds to fasten the beam in a horizontal position directly to the wall of the house itself. This work is best done with an assistant, that is, one holds and the main drills and twists.

Also, to strengthen the structure, a number of vertical bars are added.

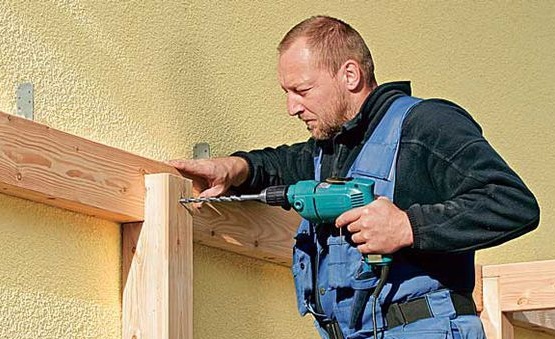

The bolts are tightened with a wrench.

That's what actually turns out.

In the joints, the author uses a metal corner.

Next, the supporting beam is laid and jibs are made, the joints are twisted with bolts and nuts.

Then comes the rafters, it is also necessary to work together with an assistant.

This is how the beam is fastened to a horizontally located beam bolted to the wall of the house.

And such a frame turned out in the end, a slope in one direction.

The front beams are reinforced by installing a wooden spacer.

A 30 mm board is sewn onto the edge of the ramp.

A professional sheet is laid on the prepared crate.

Attention!You need to start directly from the wall of the house, closely fitting the sheet to the wall.

The professional sheet is lapped and fastened with self-tapping screws with a press washer.

You should start from the beginning of the stack and go upstairs making an overlap of 5-10 cm and 1 side on the side.

On top of the laid sheet along the wall, it is necessary to sew a metal corner of tin 0.5-0.7 mm to fasten with anchors under the aluminum plate, and the remaining slots must be covered with silicone sealant.

As can be seen from the material presented, this canopy can be done with your own hands without hiring professional builders or local craftsmen) You can also save on building materials, today you can buy professional sheets directly from production, and with a small defect and defect they are released much cheaper. The beam can also be found cheaper than taking a new one from the sawmill, there are many ads where they sell used construction materials. If desired, and build and save, it's up to you.

This concludes the article. Thank you very much for your attention!

Come visit often, do not miss the latest in the world of homemade goods!

This article is for informational purposes only!