Dear visitors of the site, from the master class presented by the author, you will learn how to make the flashcard case modding, or more precisely, create it absolutely from scratch. The master for his works takes mainly copper and brass, these non-ferrous metals over time become coated with a noble and beautiful patina.

Modding originated in English-speaking countries in 1999-2000 and quickly began to spread around the world. This direction came to Russia in 2001, and in 2004 there was already a peak. Modding, and in our opinion simply “modification” implies the introduction of rationalization changes in the design of computer and digital technology. Solving problems with cooling and overheating of the system unit. Changing the design of the factory building in order to make it unique, because in our time, uniqueness and individuality is in the first place.

The author has been engaged in the manufacture of cases for flash cards for a long time and in the course of his work he gained valuable experience working with metal. And so, let's look at what exactly will be needed to create another masterpiece?

Materials1. 15 mm copper tube

2. 16GB flash drive

3. 0.5mm copper wire

4. plexiglass

5. glass tube from the lamp "Illich"

6. brass plate

7. zipper from old jeans

8. solder

9. epoxy resin

10. Poxipol

11. red LED

12. suspension from

earrings13. monometer

14. glue second

Instruments1. drill

2. mini grinder

3. sandpaper

4. GOI paste

5. tap

6. die

7. vernier caliper

8. file

9. file

10. scalpel

11. marker

12. hacksaw

13. scissors for metal

14. burner

Step by step instructions for assembling flash cards "Slide-fastener" do it yourselfIn his next work, the author decided to use the effect of the opening zipper, for which he used spare parts from old jeans. A 15 mm copper tube was also chosen as the case.

The oval shape was betrayed to the body with a vise.

Then it is cut with metal scissors in this way.

The excess is sawn off with a hacksaw.

Brass elements are extracted from the lightning.

Soldered to the body.

On the back of the housing is a fluid heating mechanism.

Makes details.

Saws seats under glass flasks.

Solder.

A valve is made of a brass plate.

Here is such a tiny fan turned out.

Set in place and riveted, but not until the end, so that the lamb can be twisted, though this can only be done with a needle, such a small detail. The author is simply "Left-Handed" 21 Century.

Production of heating elements.

Solders the details.

Cleans from solder and polishes.

Also, the author made a pipeline.

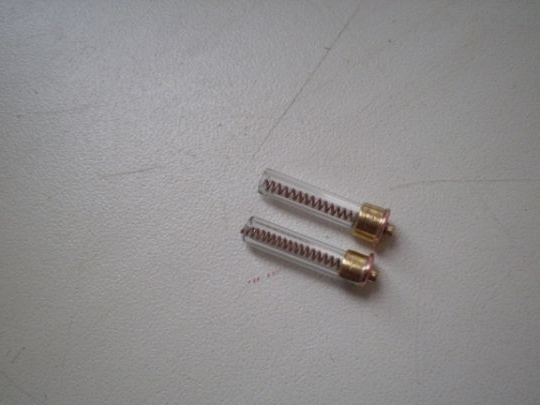

He bent the spirals out of copper wire.

Put inside a glass flask.

I glued the flasks onto the epoxy resin, and also poured it into the flasks, foamed by heating and the effect of boiling liquid turned out.

That's actually what happened in the end.

Solder cap with clasp.

Pressure gauge hole.

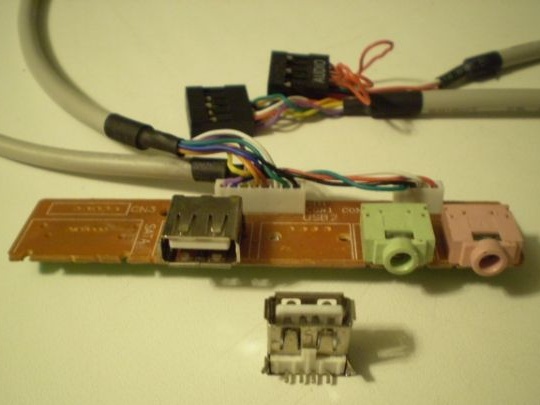

The USB connector is removed.

Paste onto epoxy.

Creates cap tops.

Gathers the insides.

Slices a piece of plexiglass with a hacksaw.

I got a pendant from an earring with a spider.

In plexiglass, he made a recess to sink the spider and covered it with epoxy.

Then the pressure gauge.

Printout on glossy photo paper.

Glued to poksipol, the arrow is scratched with a scalpel and traced with a black marker for disks.

Details of the back.

Glued onto epoxy.

Spider modding.

With the help of a drill, the author grinds shafts for gears.

Here is the result.

Drills the eyes of a spider under the installation of LED forestry.

Shafts with gears are glued, and the gears are spinning, but due to the small size, this can only be done with a needle)

The thread is cut.

The bolt-valve is screwed into place, it is necessary so that the insides do not fall out.

Placed in an ammonia bath, due to which the body was completely covered with patina.

After the bathhouse)) it is necessary to properly polish the surface using GOI paste and velvet.

Further, according to the tradition established among the masters, he made control photographs of the finished product.

Thus, the author turned out another masterpiece! The work was carried out simply jewelry and worthy of respect. Handicrafts today are not badly appreciated, because they are unique. So guys, learn from the masters, understand the subtleties of working with metals. Engage more in creativity, work on yourself, create.

This concludes the article. Thank you very much for your attention.

Come visit often, do not miss the latest in the world of homemade goods!

This article is for informational purposes only!