The author made this table when he purchased a plasma cutter. Such a table is convenient in that an arc is not reflected from its surface during operation, and lamellas damaged over time can be easily replaced with others.

Tools and materials:

- Plasma inverter;

-Marker;

Cutting machine;

-USHM;

-Welding machine;

-A circular saw;

-Gon;

- Clamps;

-Olyfa;

-Wheels;

-Profile;

-Sheet;

-Band;

-Board;

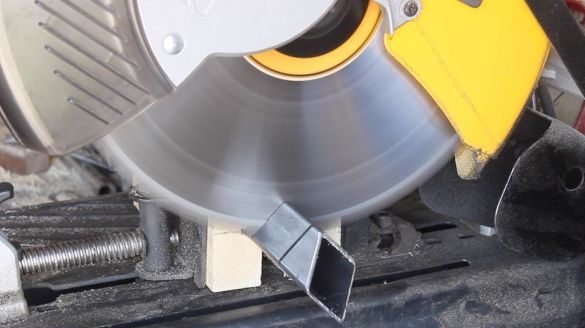

Step one: procurement of parts

The table will have a size of 60 * 90 * 90. According to the dimensions, from a profile pipe, cuts the workpiece. From the board makes a guide to hold the pipe at an angle of 45 degrees. Clamps the pipe in the guide. In the pipe makes cuts for lamellas.

Step Two: Welding

Welds the top of the table. Welds legs, wheels, bottom countertops.

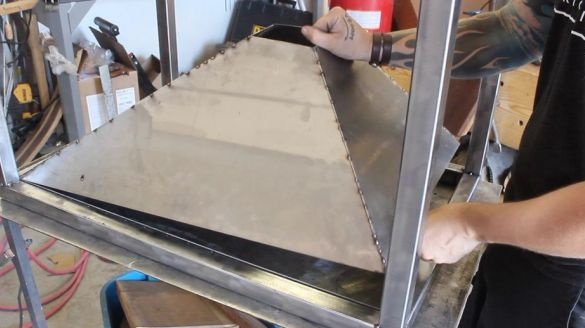

Step Three: Funnel

The next step is the author welds a funnel. Welds it to the table.

Step Four: Completion

Sets lamellas.

Welds the handle and hooks under the hoses.

It remains to apply the coating and you can begin to work.

The whole process of making such a table can be seen in the video.