Reysmus is a useful and necessary tool when working with wood and metal. Thicknesser is used to draw lines parallel to the edge of the product. It is such a tool that the author made for carpentry.

Tools and materials:

-Wood;

-5 mm Allen key;

-6 mm bolt;

- Joiner's glue;

-Super glue;

- Wood lathe;

-Turning tools;

-Hacksaw;

-Drill;

- Drills 5 mm and 6 mm;

- Pen drill 25 mm;

-Bit;

-Rasp;

-Vise:

-Pencil;

-File;

-Sandpaper;

Step One: Wood Billets

First of all, the author chose wood for the manufacture of thicknessers. The author used oak for the handle, and poplar for the block. The author also used a piece of wood for a bolt.

Step two: making a pen

On a lathe makes a handle. Handle length 7 cm, diameter 2.5 cm.

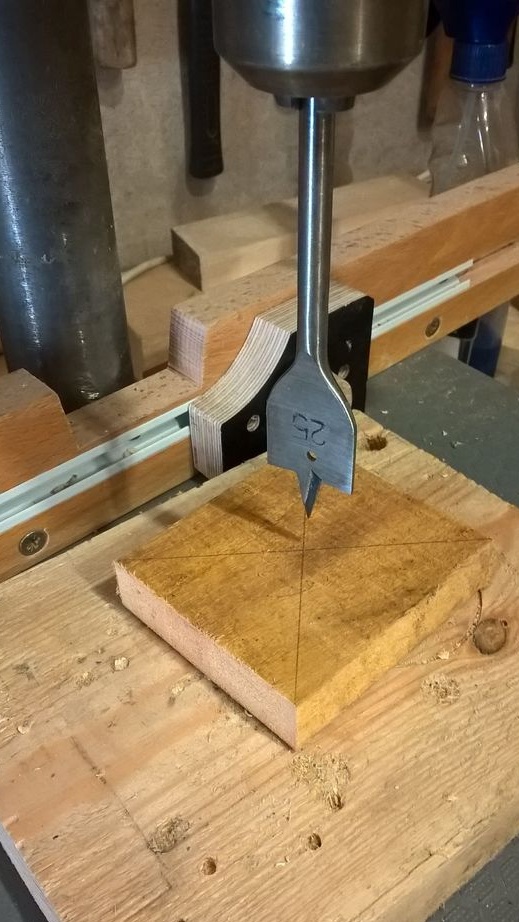

Step Three: Block

The block has the following sizes: 2.5 cm thick, 3 cm wide and 5 cm long. I cut and polished a block of the right size. I drilled a hole of 25 mm in the center of the bar. He put the block on the handle, for fixing using wood glue. At the end of the handle, from the side of the block, I drilled a through hole in the center with a 6 mm drill.

Step Four: Cutter Production

The author made a cutter from a hex key. On the short side of the key cuts off the part leaving 15 mm. Then clamps the key in a vice and sharpens the short end. Inserts a cutter into the hole in the handle.

Step Five: Bolt

The bolt has a diameter of 6 mm. In a small block, drills a hole with a diameter of 5 mm. Screws a bolt half into the hole. Apply superglue to the remaining threads. Screws the bolt to the end. It processes the bar with a rasp, giving it the desired shape.

Step Six: Groove

A pencil outlines the contour of the cutter on the end of the thickness gauge. Chisels a groove with a chisel. Now the thicknesser can be safely moved, the cutter will fit in the groove.

Seventh step: assembly and use

A hole with a diameter of 5 mm is drilled in the upper part of the block. The hole should be through between the top of the shoe and the center of the handle. Screws a bolt into the hole. The cutter is clamped with a bolt.

Reysmus is ready.

Using a thicknesser is very simple. The cutter extends to the desired length. Fixes it with a bolt. Applies a block thicknesser to the end of the workpiece. Shuffles the thicknesser by pressing the cutter to the surface of the part. A strip remains on the surface of the part.