It is quite possible to use pallets as the source material, having previously disassembled it into separate boards. Then they need to be round and polished, it turns out quite suitable. Pallets nowadays very often began to be used as a material for the manufacture of various of furniture, sheds, fences, even houses began to build the truth while the "country" but as they say, "Dashing trouble to the beginning" maybe someone will soon build a residential)

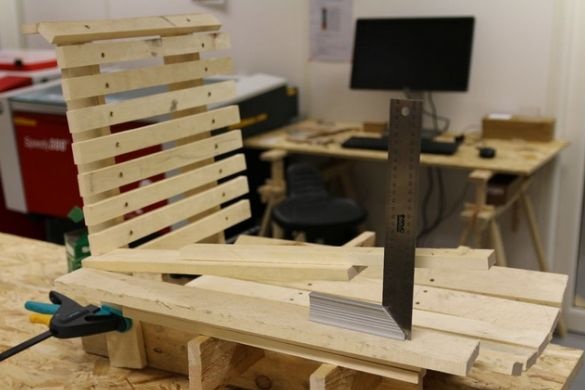

The design of the chair is very simple, all fastening is carried out using self-tapping screws. The back is a curved repeating contour of the back of a person, the seat is rounded to the beginning. The legs are crossed, fastened with 4 self-tapping screws at the crosshairs, at the base sawed at an angle.

And so, let's look at what exactly the author needed to create a chair with his own hands?

Materials

1. 25 mm board or pallet (pallet)

2. screws

Instruments

1. jigsaw

2. screwdriver

3. sandpaper

4. file

5. Planer

6. construction pencil

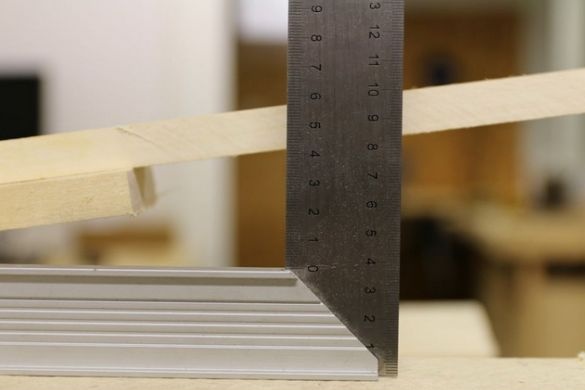

7. metal ruler

8. circular saw

Step-by-step instructions for assembling a garden chair with your own hands.

The first step is to prepare the material, namely, disassemble the pallets on the boards and dissolve them with a circular saw into the following sizes.

70x9 cm 2 pcs.

55x7 cm 4 pcs

70x7 cm 13 pcs

45x3 cm 11 pcs

The author took 2-3 pallets to do it all, you can also use the planks remaining after repair or construction. Do not throw away scraps, they are quite useful for making homemade products useful in everyday life and economy.

Also, the author prepared all the necessary tools and fixtures in advance.Note! The thickness of the self-tapping screw should be slightly larger than the diameter of the drill with which holes will be made for twisting them.

This concludes the article. Thank you very much for your attention!

Visit us often, do not miss a novelty in the world of homemade goods!