For this tool, the author took a round.

Turned it on a lathe

Then he drilled a hole with a displaced center (in order for the center to be displaced under one of the cams, the author put a small plate.)

The size of the nut hole is 19.

Then he cut the round.

Then he took a faceted rod, clamped it in a turning,

He took a drill and made a hole

Then I cut the thread under the bolt m 12.

The author has cooked both of these blanks.

After welding, I sharpened the rod.

Then he took a drill of a smaller size than a thread.

And drilled a hole in the first workpiece.

Closer to one edge, like this.

Then he sharpened the rod flush with the first part.

Next, cut off a piece for ease of use.

For the cutting element, the author took a tap. (But a riber or drill is also suitable.)

So he imprisoned him.

And went to the assembly.

The author is ready to check the tool to check its operability. To do this, he took a rusty bolt with a nut,

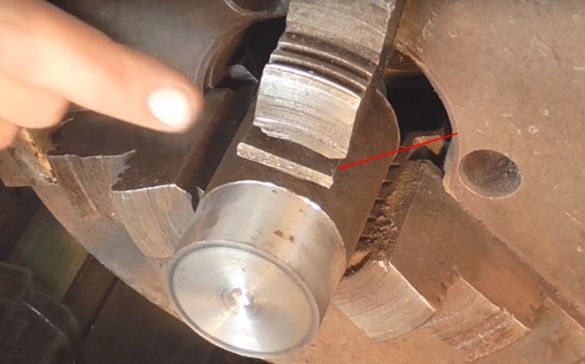

Clamped it in a vise, put a tool on it

And the key began to tighten the bolt.

Until the cutting part of the nut breaker splits the nut on a rusty bolt.

Then you can either unscrew the nut with a wrench, or do it again on the other side of the nut.

The thread on the bolt with this method practically does not suffer.

Creating a wrench in a video clip: