corner 40 or 50 size.

Two pieces of 55 cm

and two 15 cm each.

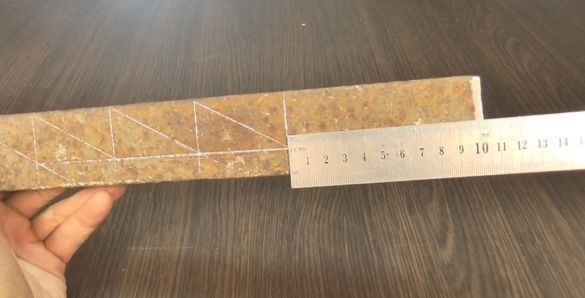

On a long corner, the author made a marking, departing from the edges by 10 cm.

and from an angle of 1.5 cm.

5 cm marked the middle.

Then he took a angle grinder and cut out according to the markup.

After cutting, he took the second long corner and attached it to the already cut, as a template

and cut out the second.

That's what he did.

Then took the short corners

and welded to them long.

Then he cut a piece of 35 cm from the spring.

Then the author made a sleeve. To do this, he took the round timber and made a hole in it under the fastening bolt.

and snapped. (the length of the sleeve should correspond to the width between the corners)

turning a small opening in the spring

The author welded the finished sleeve to the spring.

To fix the springs with corners, he made holes in the corners.

Then the author took a piece of pipe

and welded it to the spring on the other hand.

Then he sharpened the spring

Then the author collected all the details

And he began to test the instrument.

For ease of use, the author has welded the tool to a pipe, which is concreted into the ground.

Video clip on how to make a splitter: