Having your own suburban area, you should organize a place for rest on it, a terrace, a gazebo and, accordingly, make a garden furniture. Often simple home there is no way to put furniture on the street, because it will quickly become worthless, that is, it will get wet cracked, etc.

In this case, the seat and back of the chair will be typesetting, there will be a distance between the plates, which will allow raindrops to pass through the cracks and not linger on the surface. Such a chair will last a long time and will harmoniously fit into the interior of the gazebo.

And so, let's look at what exactly is needed to assemble a typesetting chair?

Materials

1. board 25-30 mm (pallet 2-3 pcs)

2. threaded rod M-10, 3 pcs

3. nut M-10, 6 pcs

4. washer 6 pcs

5. wood glue

6. wood varnish

Instruments

1. hacksaw

2. drill

3. mini grinder

4. hammer

5. brush

6. sandpaper

7. clamp

8. grinding machine

9. ruler

10. pencil

A step-by-step process for making a wood typesetting chair do it yourself.

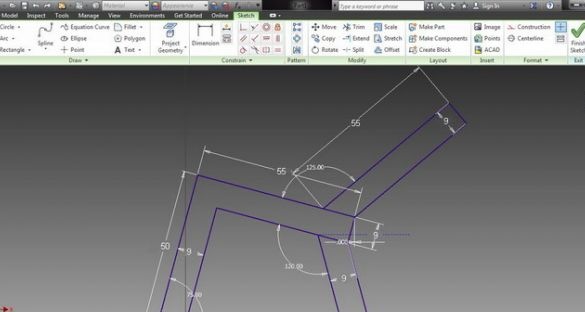

And so, first of all, it is necessary to prepare the material: for the back 17 boards 55 cm long, for the front legs 8 boards 50 cm each, the rear legs 8 pcs 40 cm each, for sitting 18 boards 55 cm each.Previously, the author made a drawing with all sizes and angles of inclination of the back, legs and seats (you can download a picture for study)Further, the master, according to a given drawing, begins to glue the legs of the chair front and rear.Then in each board it is necessary to drill holes of 2 pieces from each end.Between each board there will be a square pad from the same board. Holes are drilled exactly in the middle. For convenience, fasten with a clamp.And so with each square, due to them, the distance between the planks will be formed.First you should try on all the details.As you understand, the holes in each workpiece must match.Then, threaded rods are inserted into the drilled holes, on one side we immediately wind the nut and washer.

You have a good example, so take and do. Go for it friends!

This concludes the article. Thank you all for your attention!

Come visit often and do not miss the latest in the world of homemade goods!