Ovens of different configurations came to Russia mainly from Europe, and they began to drown them in white just abroad, that is, they came up with a chimney for the removal of furnace gases, smoke, soot, soot. At the beginning of the 18-19th century, by Decree of the Tsar, our country switched to the European standard for burning stoves "on the white", and chimneys had to be made in the villages drowning the huts on the "black" people. But drown on black, continued in rare cases until the 20th century)

From the Europeans we received such designs of furnaces as "Swede" and "Dutch" from the name it is clear that the first was invented by the Swedes, and the second by the Dutch. Both are based on the principle of fuel economy and maximum heat transfer, as well as ease of laying and, of course, functionality. The Shvedka oven includes a cooking chamber with a stove for 2, an oven for baking bakery products and pies, as well as for heating the room in which it is installed.

And so, let's specifically consider what is needed for the laying of the furnace?

Materials

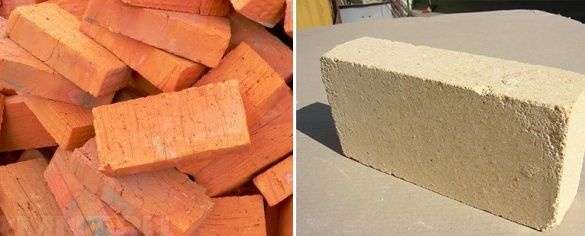

1. red ceramic brick

2. refractory brick

3. clay (or finished masonry mixture)

4. sand

5. cement

6. gravel

7. rubble stone

8. stove door

9. sheet metal oven

10. damper

11. grate

12. metal strip

Instruments

1. shovel

2. trowel

3. rule

4. capacity for solution preparation

5. plumb

6. level

7. corner

8. roulette

9. trowel

10. flashing

11. pickaxe (if the soil is rocky)

12. putty knife

Step-by-step instructions for laying the Shvedka oven with your own hands and ordering.

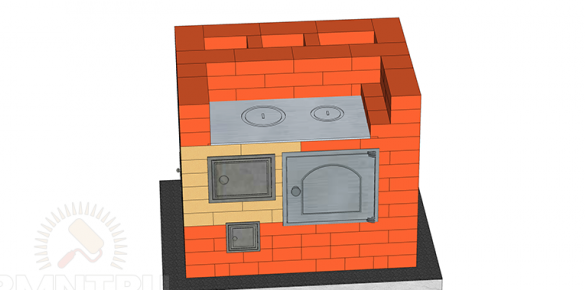

This type of furnace is very economical in terms of building material, namely, according to the author, its creation will require only 500 bricks without taking into account the pipe. On the laying of the pipe, you can also save a little by using a used red brick, the price for it is usually half less than the new one, and the thrifty owner always has a solid pile of used brick in the yard, assembled over several years by brick)

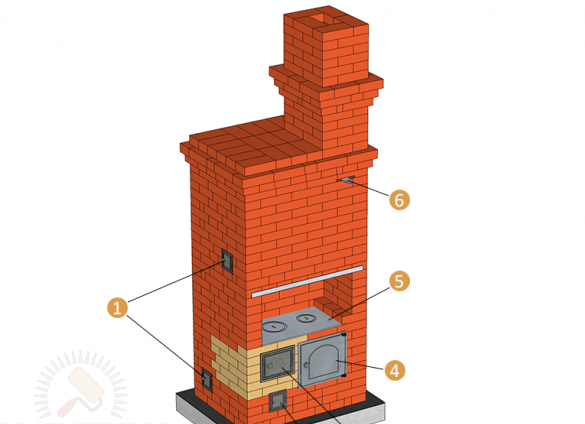

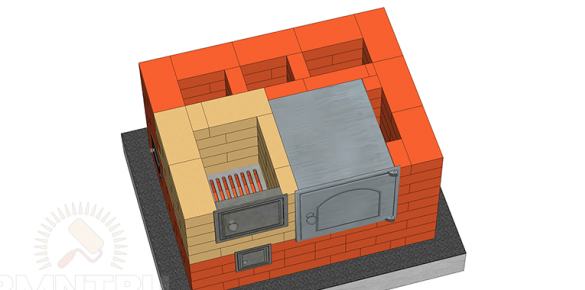

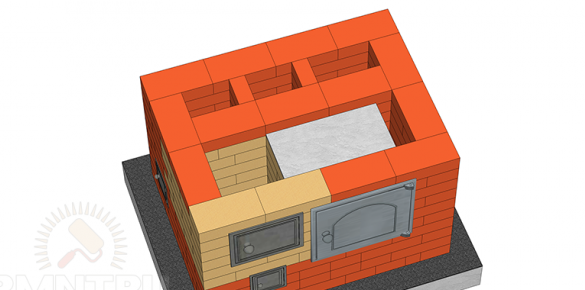

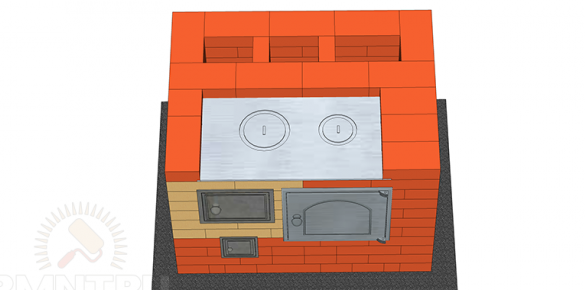

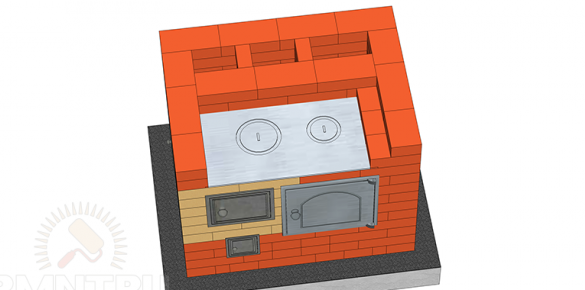

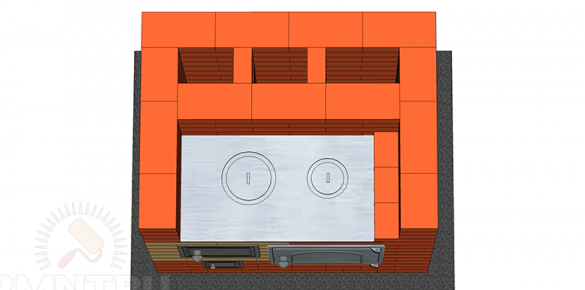

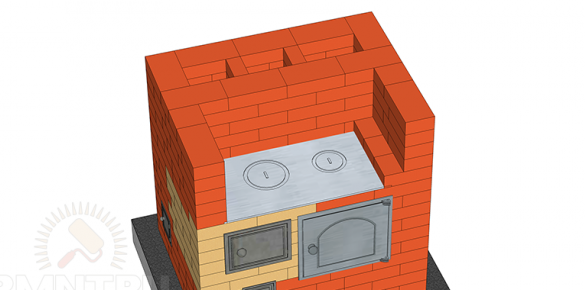

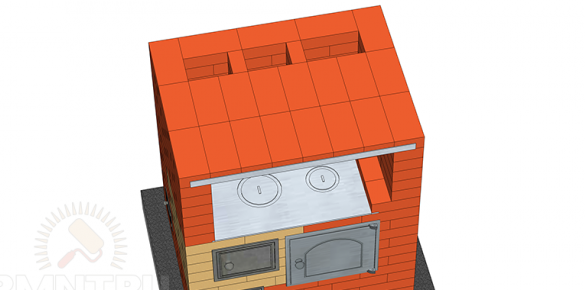

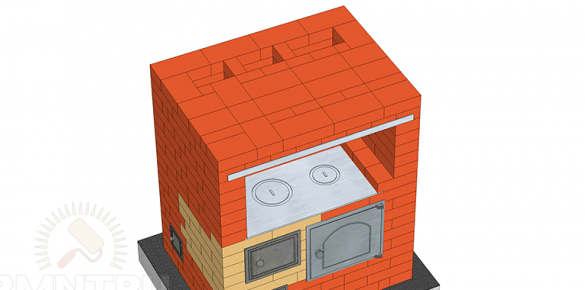

The oven includes a cooking chamber with a stove for 2 burners, as well as an oven for baking bread and pies, in general, with its small size, the oven is quite functional and carries additional utility benefits in addition to heating the room.

The furnace itself has significant weight and pressure on the ground, so a foundation is mandatory, it is best to fill it at the stages of building a house, so that it is easier to remove the soil, if the house is already built, you will have to carefully drop a hole under the foundation and remove it in buckets land to the street.

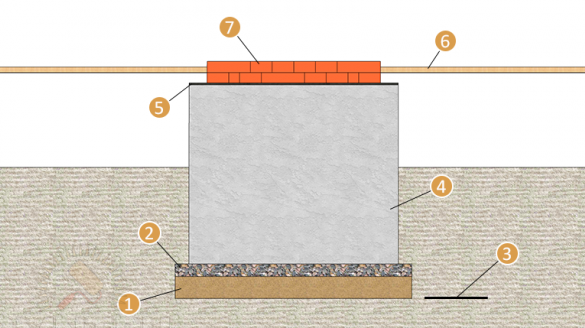

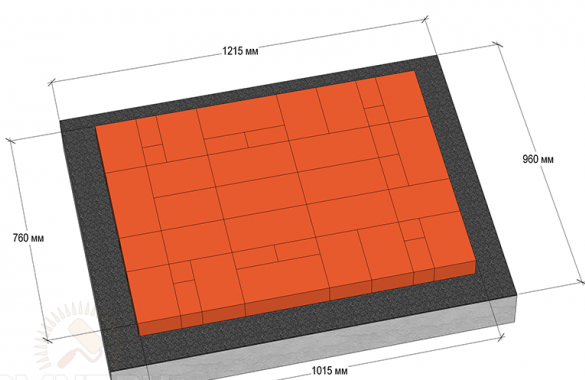

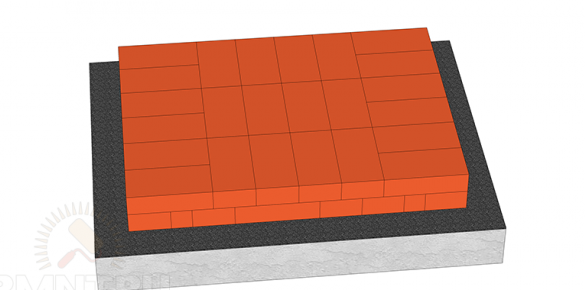

You also need to know the features of the soil on your site, the level of groundwater and whether there is a quicksand. The deepening is mainly done by 50 cm, and then the formwork is built, so that it is 5 cm lower than the floor level. The solution is prepared on the basis of cement grade not lower than M-400 and sand with a filler in the form of gravel and rubble stone. The composition is one part of cement, 2 parts of sand and 4 parts of crushed stone. All this fills the formwork to the very top and is rammed so that air bubbles come out, and the solution evenly fills all the cavities and cracks. After everything is ready, a chemical reaction and cement hardening will begin, so that this happens evenly, it is necessary to periodically wet the surface with water, so the cement will become more durable.

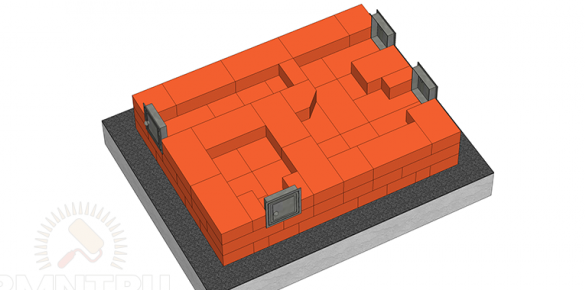

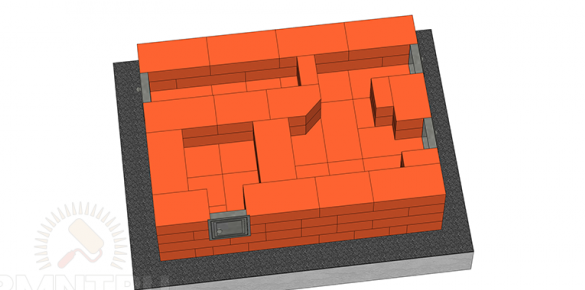

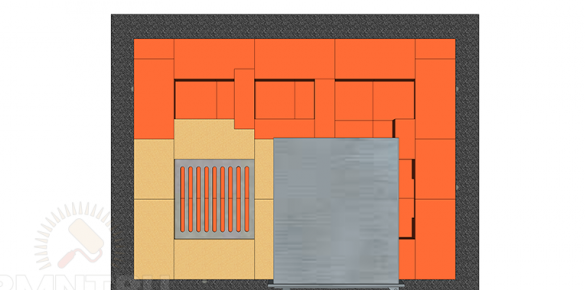

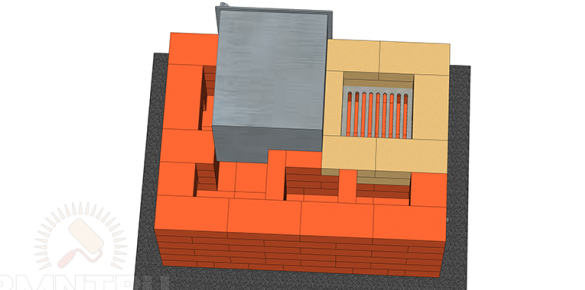

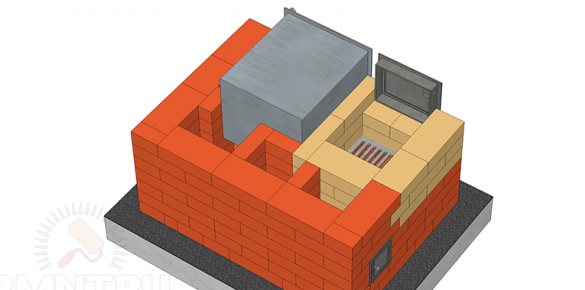

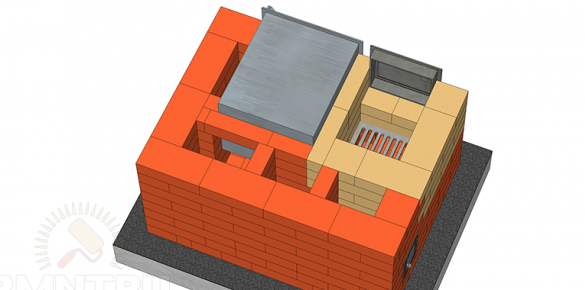

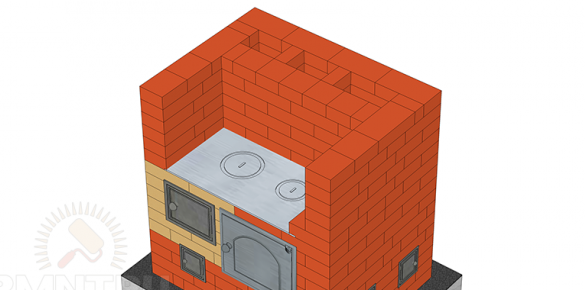

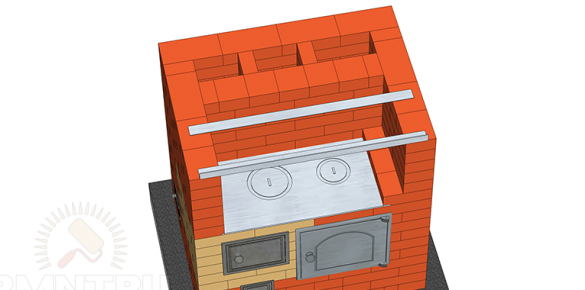

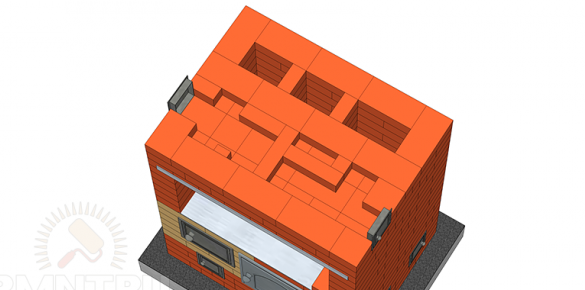

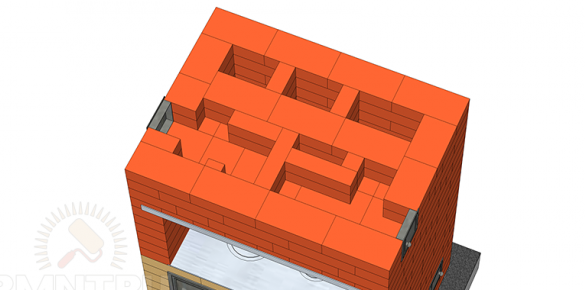

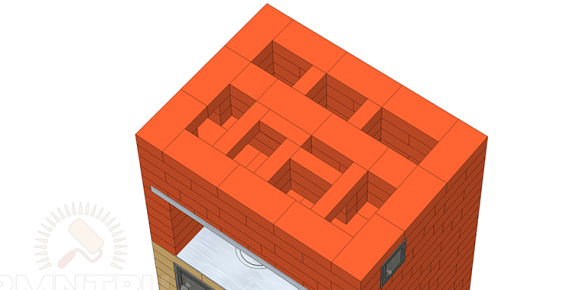

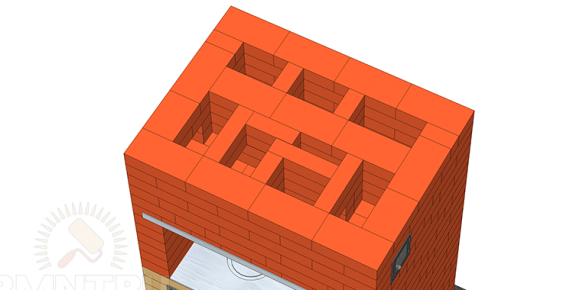

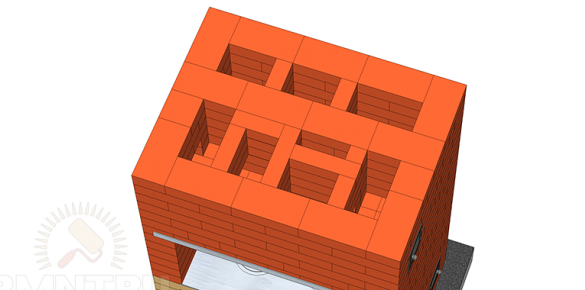

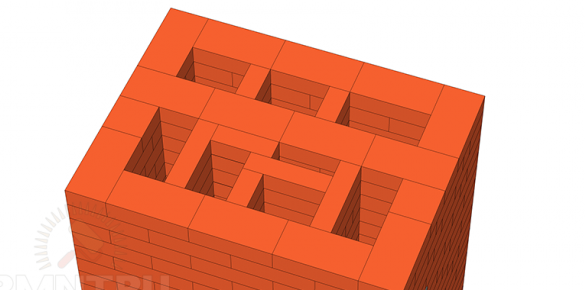

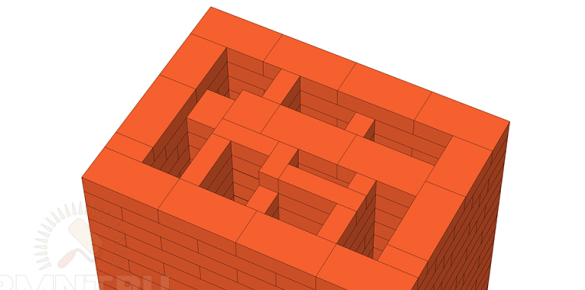

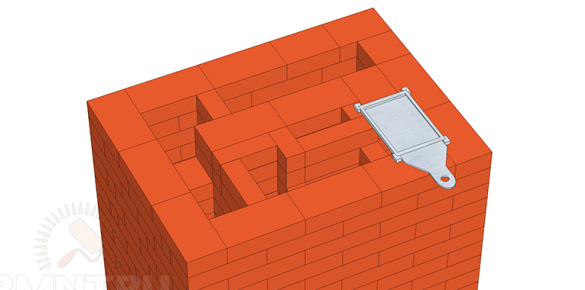

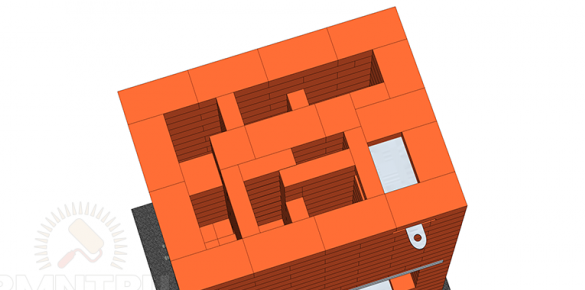

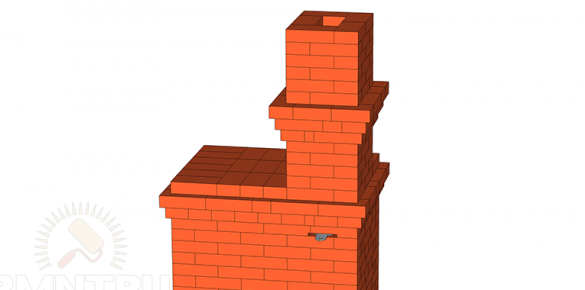

A professional tool used when laying stoves.For laying the walls of the furnace and chimney channels, the usual red ceramic brick is used, but for laying the combustion chamber it is better to take refractory, because it can withstand high temperatures and differences, unlike usual, it does not crumble and does not crack.The oven also has dampers, oven doors, a sheet metal oven (the cabinet can be welded independently), a grate, a stove, a corner. General view of the oven "Swedish".And so, first of all, a waterproofing layer in the form of roofing material is laid on the foundation, and then the first row of bricks is laid out.When laying 3 and 4 rows, an ash chamber is formed and 3 cleaning doors are installed.Further, when laying the 5th row, a furnace chamber is laid out of refractory bricks, an oven and a grate are also placed. Attention! There should not be a bond between refractory and simple brick, because they have different degrees of expansion when heated.Masonry of the sixth and ninth row performs the combustion chamber, the brick between the oven and the furnace is placed on the edge.The tenth row is a partition above the oven, and the cavity must be filled with clay-sand mortar. Next, a hob is installed.Then a cooking chamber and chimney channels are formed.

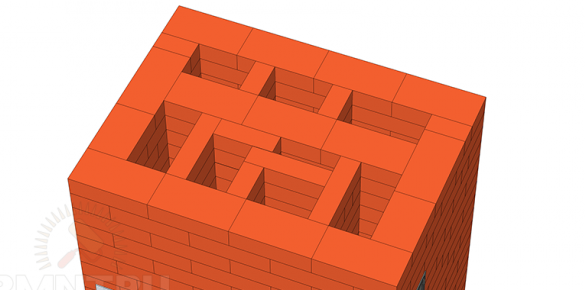

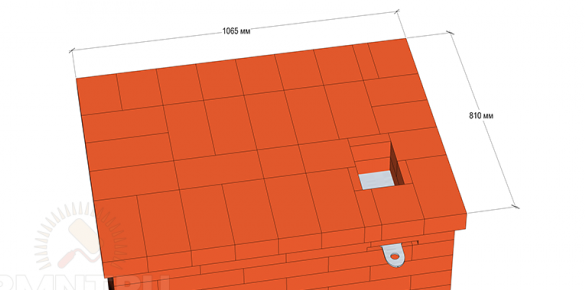

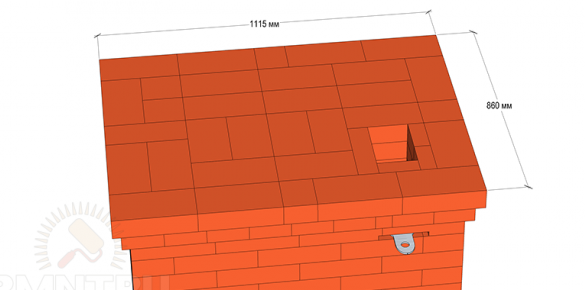

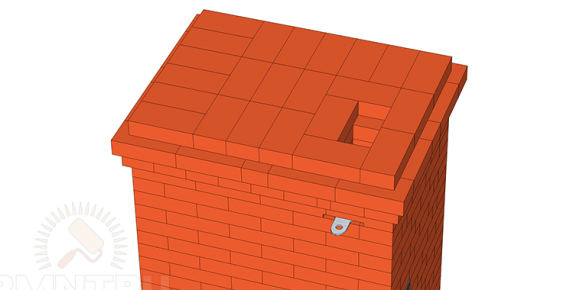

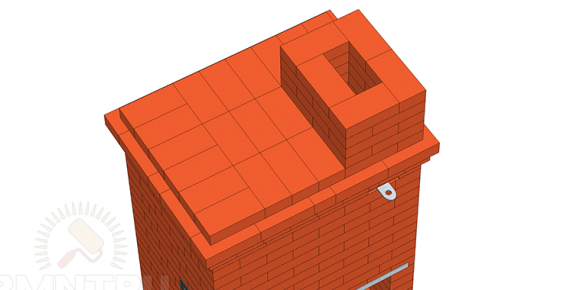

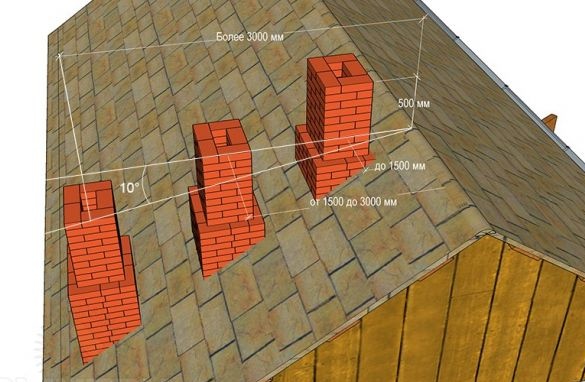

Overlapping the cooking chamber is done as follows, namely, a corner and a metal strip of 4-5 mm are laid. Then the brickwork is done again.Doors are installed to clean the channels, the gap between the door and the masonry is filled with asbestos cord.Then there is the formation and laying of chimneys.Then all the channels are closed and connected into one chimney. 5 cm extension.Next is an extension of another 5 cm to create a cornice.In the 31 row, we reduce the size of the furnace to the original.We begin to put the pipe in 5 bricks, they begin to put it when 3 rows remain to the ceiling.Under the ceiling, we are doing the expansion again.At the exit outside the attic, the pipe should be laid on the cement mortar. It is also necessary to observe the rule indicated in the photo - it is necessary that the draft is stable and the pipe is not blown out. It is also imperative to install a metal protective cap. In order to protect the pipe from precipitation and the spread of sparks.

Having such a wonderful stove in a private house, you can not worry that your electricity or gas will be turned off, your house will always be warm, light, cooked lunch and a hot kettle. In addition to all of the above, the Shvedka stove looks rather statically and will give your interior more surroundings.

This concludes the article. Thank you all for your attention!

Come visit often and do not miss the latest in the world of homemade goods!