Who would have thought that something worthwhile could be created from a copper pipe and an old fractured piece of wood? However, the stool fit perfectly into the surrounding space, exactly as the author intended.

Usually such items of furniture themselves have a rather gloomy and rude appearance. However, this is precisely what allows the interior designer to create a favorable contrast against the background of light cream shades, smooth surfaces and soft textures.

The contrast method is one of the most popular techniques in the world of interior design today. In the wake of contrast, passion for steampunk trends and the use of recyclables, this small project was born.

Its author will tell us how to make such an original stool. do it yourself. For this you will need:

1. Materials:

- An old but durable board (preferably oak or maple) with a rich texture;

- metal water pipes of suitable diameter;

- copper fittings or pieces of copper;

- epoxy resin;

- furniture screws;

- a means for protecting copper as desired.

2. Tools:

- electric drill;

- a tool for cutting pipes or a grinder with a cutting disc for metal;

- coarse and fine sandpaper;

- vise;

- a screwdriver or a Phillips screwdriver.

Step One: Finding Materials

The idea of creating this original stool of the author was prompted by an old oak board, which served in antiquity as a swing. She seemed still strong, despite her pretty aged, although, frankly, very exotic appearance.

The author already had experience with copper, so the idea was born instantly.

Use hardwood boards such as oak, acacia or maple as a base for sitting. Even in extreme old age, they sometimes do not lose their strength, and this is just what you need.

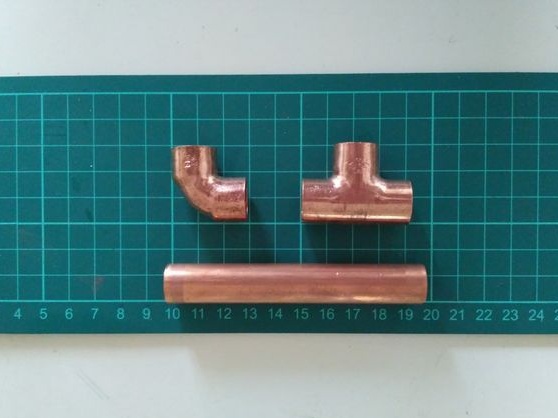

With the acquisition of pipes, everything is even simpler. The author used copper water pipes and joints - turning angles and tees.

Tubes with a thickness of 1.5-0.7 mm can be ordered on the Internet with all the necessary accessories. It is convenient to work with copper pipes of this thickness, they can be processed in a vice and cut with a conventional hand tool, including mechanical.

Step Two: Wood Preparation

Ideally, the ends of the board that you have chosen as the seat of your future stool should also look old.Therefore, try to immediately choose a board of the required size. You will not cut it.

Start by thoroughly washing the board using detergents without bleach and stain remover. Use a stiff bristle brush. Remove in this way not only dust and dirt, but also all soft, rotten wood.

Dry the board thoroughly at room temperature. Do not overdo it, because too high a temperature can lead to cracking of the tree.

Walk on the surface with sandpaper, but very, very gently. You do not need to remove the top layer of the patina, however, the surface should become smooth and pleasant to the touch. In this case, all deep cracks must be preserved in their original form.

For greater practicality in the process of further operation, the wood must be coated with a protective composition. Basically, you can use natural quick-drying oils such as linseed. Natural drying oil is great for the same purpose.

However, you can follow the advice of the author and choose an industrial composition, which in addition to oils also includes wax and some substances that prevent the formation of mold and fungi.

Such compositions have much greater reliability, prevent rotting of wood, protect it from pollution and exposure to adverse environmental factors.

Of course, this coating is designed for the use of furniture within the premises, as well as under a canopy in conditions of not too harsh climate.

Step Three: Prepare Metal Parts

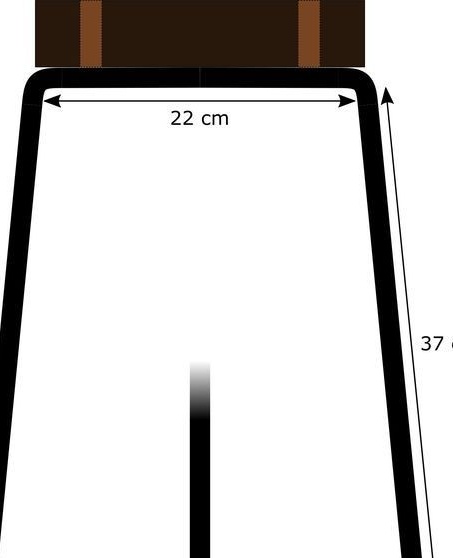

Decide on the height and width of the stool and make calculations that will tell you how much it will take for the copper tube to work.

Mark up. An ordinary pencil draws fine on copper.

To cut pipes, the author used a special mechanical tool. In order to cut the tube, it is enough to place it under the cutting disk in the place of marking as shown in the photo and press the disk against the pipe. Wrap the knife around the pipe, then press it even tighter and repeat the operation. Do this until you cut through the pipe.

You can also use a grinder and a regular metal disc. Before cutting, securely fasten the tube in a vise or, in extreme cases, use clamps.

You can purchase ready-made copper fittings such as turns and tees, or you can use metal strips to attach the tubes. However, in the second case, you will need solid experience in order for the product to acquire a neat aesthetic appearance.

Step Four: Build

The base for the seat is ready. Copper tubes are carefully measured and cut into pieces of the required length. Proceed to the manufacture of copper frame parts.

The photo shows that according to the plan, the author conceived diagonal supports for sitting. This will add to the whole structure the strength it needs.

As a rule, copper tubes are connected by soldering, but the author decided to use epoxy resin. After drying, it is a very strong and reliable material, so its choice is very justified.

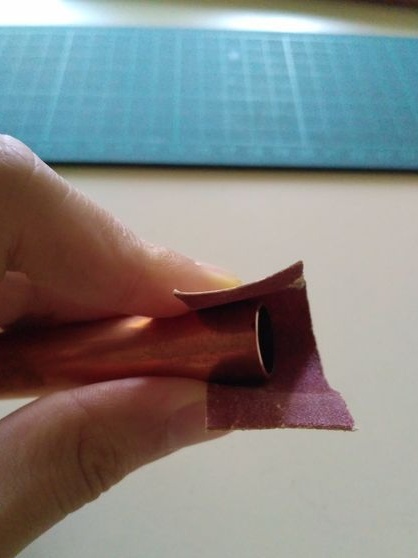

Sand the surface of the joints to add roughness. The author is sure that this way epoxy resin will fulfill its role much better. Sand the ends of the tubes as well as the inside of the joints.

Apply epoxy to the inside of the connector and insert the pipe by turning it several times in a circle. So the resin is better distributed over the surface of the connection.

The author tested the compound for strength as soon as the resin dried. Everything turned out to be very strong and reliable, beyond praise.

The diagonal supports are connected to the seat base with the flat end of the tube. To make it, use a vise. Bend the pipe gradually so that it does not break.

Drill holes in the areas where metal parts are attached to the seat.Start screwing the stool frame with the diagonal supports. Screw in screws that are suitable in length so that their tips do not protrude outward from the reverse fine side.

In the seat in the places where the screws are screwed in, the author advises to pre-drill holes so that the tree does not crack during operation.

The stool is ready! From time to time you will have to clean the copper oxide. You can also cover the metal with a protective composition that prevents its oxidation. Consult with a specialist in this regard.