The trailer has a similar shape in the form of a drop, hence the corresponding name "Drop" due to this shape, there is a better streamlining of the oncoming flow of air and wind when driving, which accordingly increases the speed of the vehicle transporting the trailer, as well as the consequence, significantly reduces fuel consumption per 100 km . That is, the streamlined trailer has not only a more attractive appearance, but also contributes to an increase in speed and fuel economy, which will certainly affect the family budget in a positive direction)

The author himself assembled the trailer on his own from scratch, welded the frame from a professional pipe of rectangular cross section, installed a bridge, hubs and wheels R-14, you can additionally install springs, you can also change the wheels to R-16 but you also have to change the hubs with 4 studs on 6 studs and put the wheels from the SUV, depending on the terrain on which this trailer will be transported.

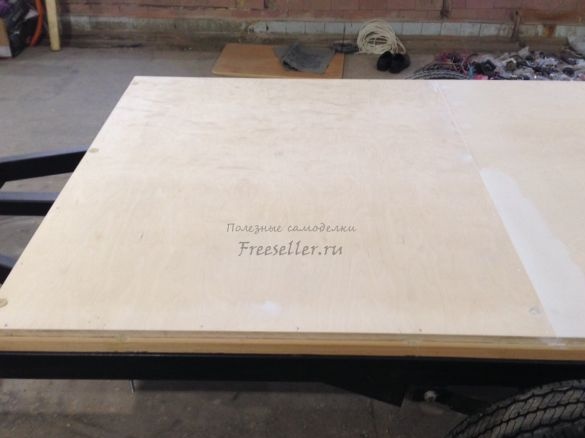

The case is assembled from a rail 30x30 and 40x40 mm, as well as birch plywood 6 mm, a door, windows, hatches are installed, linoleum is laid on the floor. There is a folding compact bed, a fan and an LED ceiling for lighting are installed on the ceiling.

So, let's look at what exactly the author needed to build a car trailer?

Materials

1. rectangular tube

2. rail 30x30 and 40x40 (larch)

3. 6 mm birch plywood

4. door, hatches, window leaves

5. aluminum sheet

6. insulation in the form of polystyrene foam and mineral wool (it is also a noise insulator)

7. R-14 wheels

8. linoleum

9. LED light

10. ceiling fan

11. wiring

12. side lights and brake light

13. bumper

14. stainless steel sills

15. wings 2 pcs

16. bolts, self-tapping screws, nuts, washers, engraver

Instruments

1. welding machine

2. drill

3. Bulgarian (angle grinder)

4. jigsaw

5. set of wrenches

6. screwdriver

7. roulette

8. clamps

9. marker

10. pliers

eleven.laser level

12. corner

The step-by-step process of assembling a car trailer drop "Teardrop" with your own hands.

The author created this trailer according to his own drawings, first of all he welded a frame from a professional pipe of rectangular cross section and installed a bridge, hubs and wheels R-14.Next, a larch rail of 30x30 mm is attached to the frame, fastening a bolt-nut and washer naturally.Birch plywood is laid on a fixed wooden platform. After that, the walls of the van are made of the same rail and birch plywood.This type of trailer has a luggage compartment.

Then the walls of the trailer on the outside are finished with sheet aluminum.A door, hatches and vents are installed.Inside the cabin, a fan is placed on the ceiling, as well as an LED lighting shade.

Also, electric brakes were installed on the trailer, which gives additional safety when driving from a steep descent and sudden braking.

That's all. Thank you all for your attention!

Come visit often and do not miss the latest in the world of homemade goods!