The variety of shapes and designs of coffee tables is striking. Sometimes it seems that this is the most popular item of furniture of all times and peoples. Despite its modest dimensions and quite prosaic functions, not a single table is like another. But this is natural.

This simple piece of furniture is a wonderful simulator, not only for a novice furniture maker, but also for an eminent craftsman who, at such a modest training ground, can easily turn his most original and incredible ideas into reality.

For the manufacture of coffee tables, you can use any of the known materials, it is as plastic as the designer. It can be wood, metal, glass, and even paper and plastic.

Of course, the classic coffee table is made of natural wood. So he was born several centuries ago. Wooden tables are popular to this day, since natural wood allows you to create even the most incredible engineering projects.

The author of this master class positions his coffee table as a typical echo of bygone days and refers to it only as a rural coffee table.

In order to make a simple coffee table made of wood, you will need:

Materials:

- bars and boards made of natural wood;

- glue for woodwork;

- alcohol-based stain or protective decorative toner oil;

- furniture varnish;

- furniture screws or wood screws, nails.

Instruments:

- electric drill;

- miter saw, jigsaw or hand saw for wood;

- grinder (preferably tape);

- screwdriver;

- fine sandpaper;

- paint brushes, soft tissue without lint;

- construction tape measure;

- square;

- a pencil.

Step One: Detailing and Dimensioning

He will consider that the sketch of the product is in your hands. If you do not plan to make any structural changes to the design of this coffee table, take this ready-made idea as a basis.

You can use fresh lumber from the supermarket or take used materials. After high-quality protective and decorative processing, no one will notice the difference. The main thing is that the wood remains strong.

However, fresh lumber must be properly dried.In no case do not use raw wood for furniture production, otherwise you will encounter a number of insurmountable problems during the operation of the product.

Decide on the final dimensions of the table and on paper list all the details that you should make in the process. Indicate their exact size and quantity.

Step two: marking parts and their manufacture

The author used ready-made bars from the supermarket for work, standardized for one size. This is the easiest and most convenient way for an amateur. However, if you have the opportunity to properly process wood parts, why not just do so. Moreover, even with such small volumes of material, you can save a lot of money.

Saw a board of suitable thickness into the bars. Use a circular saw for this. In order for all parts to have exactly the same dimensions, they should be processed on a surface planer. The gage allows you to produce lumber of a certain predetermined size. For example, a bar 40 x 40 mm, which you will need in order to assemble the frame of the coffee table.

Mark the frame parts and cut the bars into pieces of the length you need. If you have a miter saw - just great. It allows you to make a neat, even cut with one touch, which does not require adjustment during the assembly process.

Also prepare worktop blanks. It consists of several boards fixed to the frame. You can use any kind of wood other than the one from which the frame of the coffee table is made. For example, oak.

Choose boards with a beautiful pattern and rich texture. The tool for the protective and decorative processing of worktop parts does not have a dense coating, so the natural texture of the wood will be clearly visible on its surface.

Saw off the worktop parts to the specified size and carefully grind. For grinding even flat surfaces it is best to purchase and always have a belt sander on hand. It allows for more uniform processing. Grind the frame details as well.

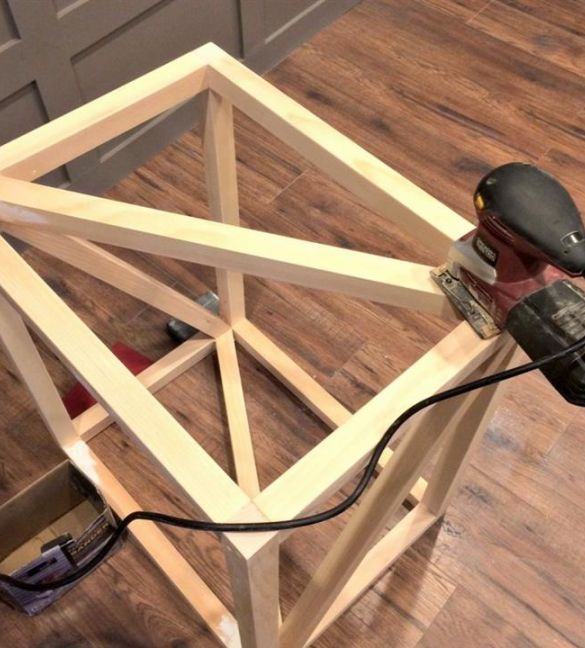

Step Three: Assembling the Coffee Table Design

Use diagonal pocket holes to secure parts with screws. Later it will not be difficult to hide them under a layer of sealant or putty, and the product without visible connections will look much more neat and professional.

Mark the joints of the frame parts and drill holes. Use glue in addition to screws. Apply a small amount of glue to the joint, press the parts against each other and screw in the screw to fix it. If you can do this operation alone you can hardly, use clamps.

Thanks to the combination of screws and glue, you do not need to wait until the glue has completely hardened and the joints will gain the necessary strength. The screws will do the job, and you can assemble the frame in one go.

The author carried out grinding after the assembly of the structure. Here, craftsmen are usually divided into two categories: some prefer a detailed machining with a grinder, and the second prefer processing a solid product. Choose the method that seems more convenient to you.

You will return to the countertop later. In the meantime, time to move on to the decorative processing of the details of the coffee table.

Fourth step: protective and decorative processing of the frame with artistic effects

The author wanted to achieve the effect of aging of the tree during processing. This would mean the presence of artistic scuffs on the frame, painted white.

But, since the tree was used light, it was not so easy to achieve visible scuffs. True, a solution was found very soon.She applied a stain to the surface of the frame, which gave it a deep dark tone, and painted a layer of white paint on top of the frame.

After the coating has dried, the author carried out selective grinding of the frame in order to identify abrasions.

Work manually using fine-grained emery paper and gently sand the coat of paint where it looks organic. The stain penetrates the layer of wood, however, too thorough grinding and can remove it, but you definitely do not need it.

In order to protect the coating from the burden of years, apply a coat of varnish. Wait for it to fully harden and stop sticking to your hands. Evenly, without much pressure, sandpaper over the entire surface and apply a second coat of varnish.

Step Five: Worktop Preparation and Final Assembly

You can also use an alcohol stain to process worktop parts. This is an inexpensive but effective tool for tinting wood.

For these purposes, protective and decorative oil is also suitable. It is much more expensive, however, it has several advantages. As a result, you will get your chosen tone with a very soft and noble shine.

In any case, the choice of material is yours. Tone the countertop and fix its individual parts on the frame. Use ordinary nails for this. Unlike screws, they will not be evident.

Varnish the countertop by analogy with the frame. An extra coat of varnish can be applied for abrasion resistance.

Your homemade coffee table made of wood is ready!