This type of manufacture of rope from natural material will greatly help a person in the wild to survive, for example, to connect raft logs to each other or to tie up the huts, as well as to save comrades who have landed in a deep hole or mired in a swamp bog. In general, the situation in the campaign may be very non-standard, and sometimes just shocking the mind of the average man. Also, this rope can be used as a tourniquet to stop bleeding and tighten tires in fractures. Anything can happen ..

And to make a rope from the bark of young willow trees, branches, hazel, etc., is very simple, for which you only need a knife and a little patience)

The first step is to prepare the required number of young liquid rods and making incisions to strip strips of bark from them. Further, the obtained blanks are simply braided into a pigtail. How to weave a pigtail surely everyone knows)) And if not, then learn, it’s not for you to poke around in an iPhone))

And so, let's take a closer look at the whole process from start to finish.

Materials

1. rods of young trees (willow, branches, walnut, etc.)

Instruments

1. knife

Step-by-step instructions for weaving a rope from the bark of a tree do it yourself.

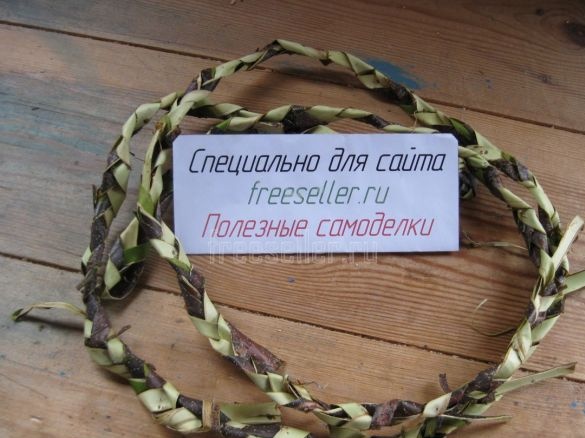

To get the rope in the field we need to get twigs and branches of young trees, the tree species can be essentially any, the main thing is that the bark is strong and easy to remove. We make the billet with a knife, but if it turns out that you don’t have a knife, we simply break the rods with our hands, and then at the splitting point we pry off the bark and peel it off.We make cuts with a knife, in this case the author made 3 cuts and as a result will receive 3 strips of tree bark.Then gently peels off the bark from the trunk.Here is a strip should work.We do the same with the rest of the rods.The number of strips depends on the desired length and thickness of the rope.After that, we begin to braid, make a crosshair and fold one end.Weave a three-end braid.As weaving, the length of the strip will end and should be increased by weaving together by connecting 15-20 cm with the previous strip.After you finish weaving the rope, then the ends should be fixed so that they do not come apart, but to do this simply, knit a knot and that's it)Here is a rope turned out.Further, the author conducted a strength test of the rope, namely, made loops along the edges of the rope and tied a weight of about 8 kg, hung it on a nail.The rope holds the load perfectly.After which the master increased the load to 20 kg.Holds, only the rope stretched slightly.Then the author decided to hang himself on a rope, having done this he straightened a nail))He continued the tests: he stood with one foot on the end of the rope and with two hands pulled the other end upwards to break, with effort the rope broke in the middle, but the loops remained intact. Thus, a rope woven even from 3 strips will be able to withstand a load of 20-30 kg, and if folded in two or three it will freely support a weight of 60-90 kg, only the source material will naturally need more, and this is a very real alternative to a factory rope.

It is possible to make it quickly in the conditions of a campaign, and you don’t need special skills and tools, as usual everything is simple, accessible and understandable. A step-by-step instruction is presented to you, remember it may come in handy!

That's all, thank you all for your attention!

Come visit often and do not miss the latest in the world of homemade goods!