This table was specially made by the author to order and shot a detailed photo and video report so that people could repeat and do something like that if they wanted to. It should be said right away that there will be a lot of material in the form of a metal channel, and the design itself will be quite massive, but as they say "A successful goal justifies the means"

The table has 2 drawers on furniture rails and a glued wood worktop. By the way, the author provided for the fact that wood in a metal frame will be exposed to temperature extremes, and this can lead to its ship. So, he first sawed the boards into separate slats, and then turned 900glued into a single board and several boards in a large countertop. Then the table was painted red; this color is mainly used in factories for painting machines. After which the master made patination and aged the surface, it turned out very cool.

And so let's look at how the author created a table in an industrial style and what exactly did he need for this?

Materials

1. channel

2. corner

3. sheet metal 2 mm

4. bolts, nuts, washers, grovers

5. paint

6. flushing

7. stain

8. 40 mm board

9. furniture rails

Instruments

1. welding inverter (semi-automatic)

2. Bulgarian (angle grinder)

3. drill

4. drilling machine

5. magnetic corner

6. clamp

7. plasma inverter

8. polishing machine

9. boron machine

10. metal ruler

11. corner

12. roulette

13. marker

14. rags

15. stationary cutting machine

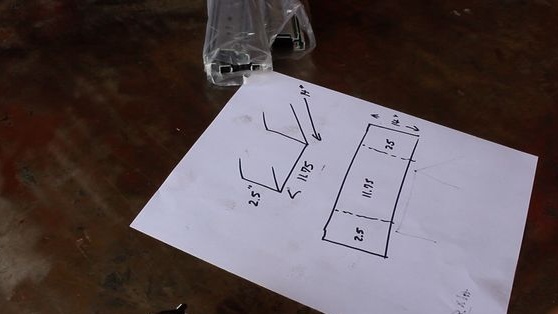

Step-by-step instructions for creating an industrial-style desktop do it yourself.

And so, first of all, let's see the video from the author, and then we will analyze everything in stages.

As you can see from the video, the work was done very painstaking and time-consuming.The master responsibly approaches his work, everything is exactly in line and observing the angles. Test work! Well done!

The author has an old truck on which he carries metal, boards and other material necessary for products.

The table is pre-wiped with acetone to degrease the surface, and then painted in red with a spray can, in total 3 cylinders were spent.

After the table was painted and dried out, Zack brought a few boards for the countertops on his truck.

The work was very painstaking, but the result is certainly worth it. Moreover, the author also sold it profitably for a good price. The industrial style is only gaining popularity, and the main demand for such furniture is naturally from wealthy people, so you can take the idea into service and use it as your own business.

A step-by-step instruction is presented to you, and it is up to you to decide whether to do it or not.

That's all, thank you all for your attention!

Come visit often and do not miss the latest in the world of homemade goods!