Today, pallets are a universal material that is used in construction, manufacturing of furniture, fences and many more where else, but about the creation of utensils from a pallet, few have probably heard))

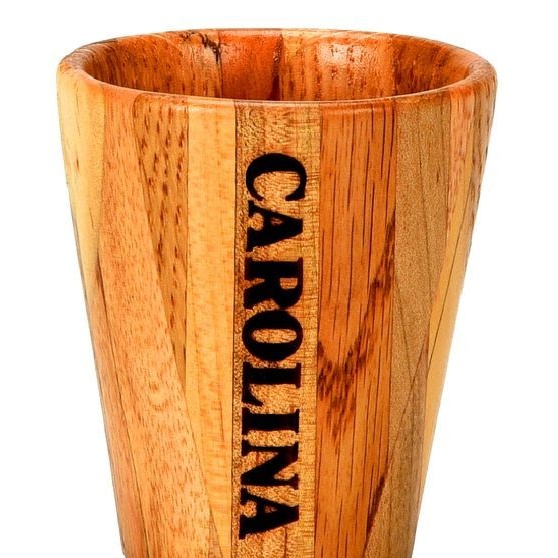

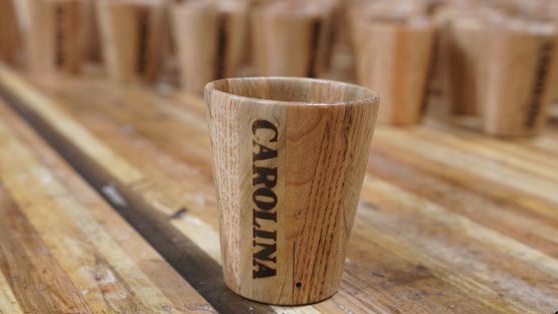

Glasses of this wood are completely safe and you can drink water and other drinks from them, they are coated with varnish and a special waterproof composition.

To make a wooden cup from a pallet, it is necessary to get these very pallets (of different types of wood). The author picked up several dozen flights near a shoe store, shoes were brought to them. Dismantled them on the boards in the same place on the spot and loaded them into the car interior.

Having brought the material home, he immediately began to process it, first he passed it through the thickness gage and cut it off, then cut off the uneven edges. Further, the workpieces are glued together and pulled together with clamps, remain in this position for 24 hours. After that, the screed is removed and the blanks are rounded on a circular saw, then cut into the length of the glass. Wooden ingots are machined on a wood lathe and the cup itself is already turned directly. It is varnished and a special waterproof composition.

And so, let's look at how the author made wooden cups from pallets.

Materials

1. pallets (preferably different types of wood)

2. wood glue

3. varnish

Instruments

1. Thicknesser

2. circular cutting saw

3. circular saw

4. clamp

5. drilling machine

6. wood lathe

7. device for disassembling pallets

8. nail puller

9. sandpaper

10. ruler

11. pencil

12. gas burner

13. metal mark

14. roller

15. incisors

Step-by-step instructions for making wooden cups from pallets do it yourself.

The author came up with an excellent idea for turning waste into expensive handicrafts that are in good demand and the master only manages to take orders for those who want to get the treasured wooden cup from the pallet)

The work was carried out very serious and painstaking, but the author filmed everything in great detail and in the smallest details on a video that is really nice to watch, as they say, "You can endlessly look at three things, how fire burns, how water flows and how a person works." with you and see)

As mentioned above, at first the author found a lot of pallets near the shoe store, where he was given them completely free of charge, and he gladly dismantled several dozen pallets right on the spot with a special device for parser analysis.

Step-by-step instructions are provided for you, so go for it friends!

That's all, thank you all for your attention!

Come visit often and do not miss the latest in the world of homemade goods!