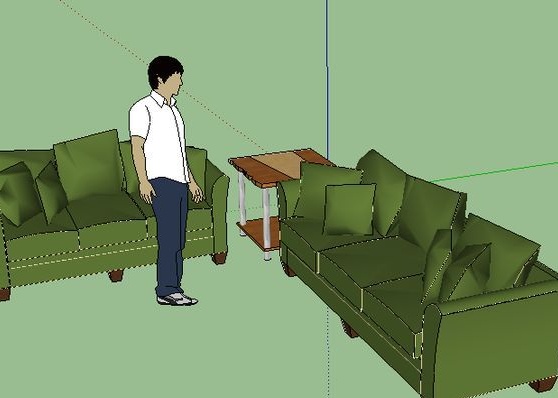

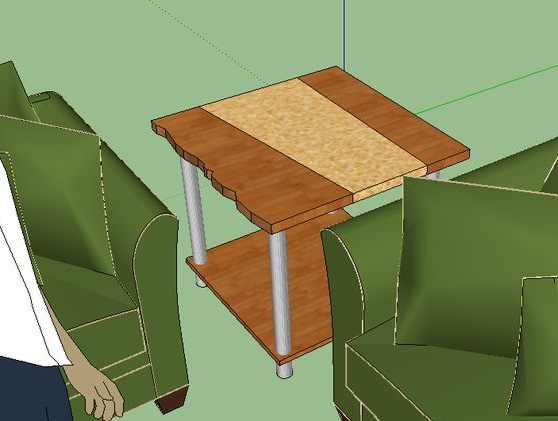

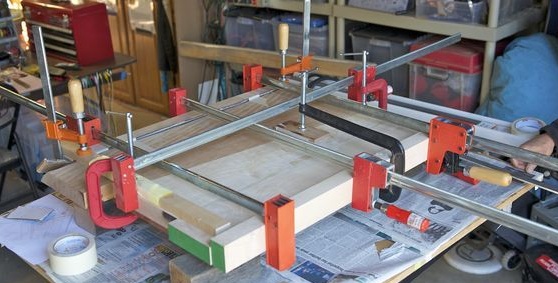

This table was made by the author purely for himself, in his house where there was already similar furniture. Tables and chairs made of natural wood look very beautiful and fit into any interior. At first, the master completed the design project on the computer and made 3D modeldrawing with printed dimensions. Maple and cherry wood combined into a single tabletop was used as the starting material. Initially, a square frame was assembled with longitudinal grooves for installing crackers, by the way, thanks to them, the tree does not crack and does not warp when the humidity or temperature increase or decrease.

The author made racks of threaded rods, and on top of them he put on tubes with stainless steel spraying. At the bottom of the table I placed a small shelf where you can put various objects. The wood is finally coated with several layers of varnish to emphasize the nobleness and texture of the wood pattern.

And so, let's look at what the author specifically needed to make the table.

Materials

1. wood board 40 mm (maple and cherry)

2. threaded rods

3. nut, washer

4. varnish

5. sprayed metal tubes

6. crackers

7. screws

Instruments

1. circular cutting saw

2. circular stationary saw

3. hacksaw

4. clamp

5. vise

6. hacksaw

7. wrenches

8. drill

9. screwdriver

10. ruler

11. roulette

12. pencil

13. brush

14. sandpaper

15. file

Step-by-step instructions for creating a table made of natural wood do it yourself.

First of all, the author made a 3D model of the future table on the computer with the drawing of all the necessary sizes, this allows you to perfectly prepare for the upcoming work.

Step-by-step instructions are provided for you, so we take and do it. Go for it friends!

That's all, thank you all for your attention!

Come visit often and do not miss the latest in the world of homemade goods!