If you have an old brake disc from a car lying around, do not rush to throw it away, because this is an excellent source of durable metal. In fact, the author of this homemade demonstrates how to make a high-quality garbage knife.

For the manufacture of such a knife does not need hardening, since it is simply formed from a finished piece of hardened steel and is well sharpened. The main tool for creating knives is a belt sander, as it is she who creates the profile of the knife, polishes it to a shine, removes bumps, and also grinds.

All such home-made products require special attention in the field of safety, since when working with metal and a tool for its processing, you can cut yourself, burn yourself, or receive various other injuries.

This is what happens if you do not adhere to safety rules. Not for the faint of heart!

Materials and tools for homemade:

- old car brake disc;

- belt grinding machine;

- grinder;

- materials for creating a pen (for example, a deer horn);

- epoxy (for gluing the handle);

- pins for assembling the handle;

- drill;

- paper, pencil, ruler and other accessories to create a knife template;

- polishing wheel;

- impregnation for the pen and more.

The process of making a knife:

Step one. Make a template and cut out the blade

The first step is to create or find a blade profile ready on the Internet. Then it is applied to paper and cut out. Then it remains to attach, and it is better to stick the template to the metal and cut. Here you can use various tools, most often it is a grinder.

Step Two We form a blade profile

At this point, the author creates a blade profile. Professionally, this work will be performed by a belt sander, and of course, experience is needed here.

Due to the fact that the brake discs have holes, one of them will be located on the knife in any case. But this is not a problem, it can be used for some useful purposes, moreover, it facilitates the knife. If you still decide to remove the holes, you can solder them, and then polish them well, as a result, this place will not be visible.

Step Three Handle manufacturing

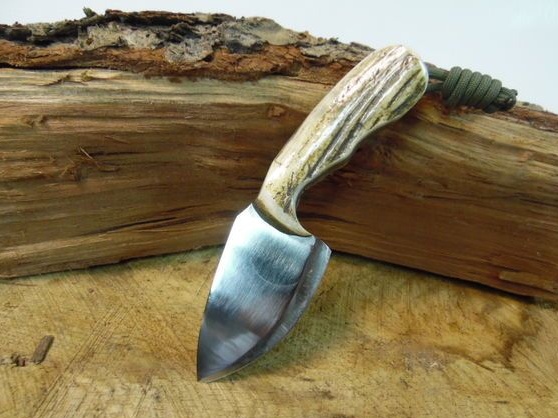

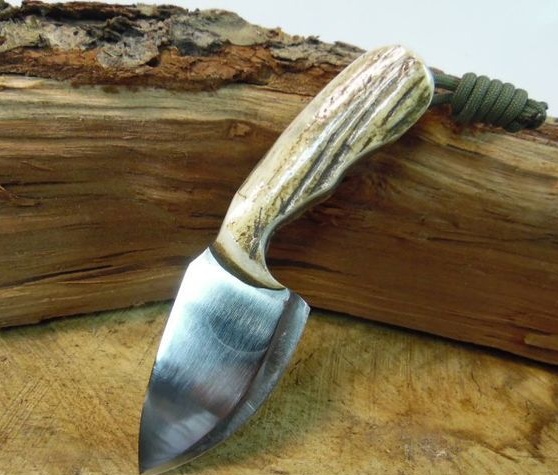

The author decided to make the handle out of a deer horn. But it can also be made from any wood you like. The workpiece must be cut to the desired size and then ground the main profile. Here again the belt sander will come to the rescue.

To attach the handle, it can be cut into two parts or just make a groove into which the back of the blade will enter. For reliable fastening, through holes are drilled in the handle and in the blade, and then pins are inserted. But it’s not so easy to drill a brake disc, in this case the handle can simply be planted on good glue, for example epoxy.

Before gluing, the components must again be tried on to each other and sanded first on the grinder.

Step Four Glue the handle

The author glues the blade to the handle using epoxy. Previously, it must be applied to the groove in the handle, and then insert the blade there. Epoxy should be so that some of it crawled out, this will provide a good connection. The handle will need to be clamped in a vice.

When the glue dries, the knife goes to the final grinding. Now you need to smooth out all the bumps, as well as align the handle and blade flush.

At the same stage, the blade can already be sharpened, gradually reducing the grain size on the grinding machine. The finest sharpening is achieved by using water stone.

Step Five Final revision of the knife

At this point, the author inserts into the pen and braids a piece of the cord. This adorns him, and such a cord can be useful in a campaign for some purpose. During further work with the knife, its blade should be sealed with masking tape or paper, so as not to cut yourself.

Now the knife is well polished with a polishing disc. In conclusion, it can be coated with oil or a special solution so that it does not rust.

That's all, now the knife is completely ready, it can be tested. If the blade profile is machined correctly and the blade is well sharpened, then the knife should calmly cut the paper.