For this device, the author took a piece of steel round timber. And he will use it as the basis of the device.

He then took a half-inch metal pipe.

And he began to manufacture bushings, for this he made two oblique cuts on the pipe, a kind of two teeth.

The author then trimmed these teeth.

Like this.

Then he cut off this piece.

For the second sleeve in the remainder of the pipe, he made teeth similar to the first.

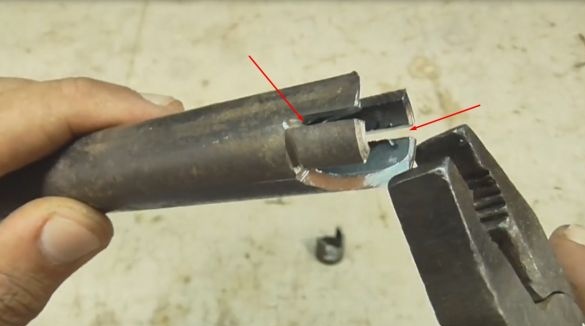

Then he put the sleeve and pipe with teeth on the shaft. (round timber)

Thus, the author can see where you still need to trim the teeth.

The teeth should not enter each other.

Then the author cut off the second sleeve, only it should be longer than the first.

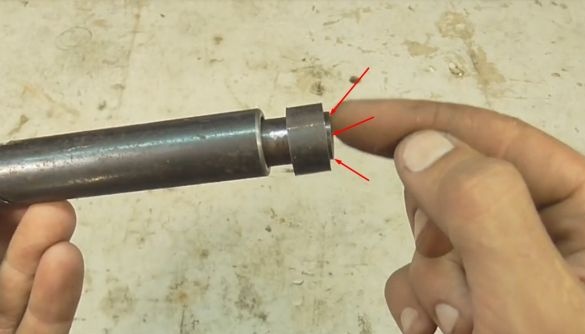

Then he stepped back a little from the edge of the shaft and welded a short sleeve to the shaft.

After welding, the author also put a long sleeve on the shaft.

Then he cut off a piece from the pipe, put on top of the sleeve on the shaft

And I welded it in such a way that a small stroke would remain at the long sleeve.

For the case of the device, the author took the pipe three quarters

I sorted it out a little

And for a prettier look, the cutter removed from her old paint and rust.

Having placed the device in the case, the author needs to weld the case to the long sleeve

To do this, he drilled twelve holes in the casing.

Then he put the case back on the device

And I welded the sleeve to the body through these holes.

Then he found a bolt of a suitable size and cut off his hat on it,

inserted into the case,

And well welded. (The author needs this to ensure that when the hammer hits the device, the edge of the case rolls more than once)

And in the end, the author has to make a square at the end of the shaft

To change different nozzles for screwdrivers or keys.

Here is a device turned out by the author.

And in the end, of course, a test from the author.