To create this tool, the author took the following materials:

100 mm long tube with an internal diameter of 9 mm

hairpin M8

steel screw 2 pcs

and wing nut.

First of all, the author needs to flatten one edge of the tube, for this he put a round in the tube (so that the tube does not deform) but not to the end,

He clamped it in a vice and squeezed it well.

Then at one of the edges he made a groove with a round file.

Further, on a milling machine, he made longitudinal holes on both sides.

At the next stage, the author took the screws and cut off everything superfluous from them (the threaded part and the hat.)

Then he made a through hole in the tube of such a size that the cut-off screw would fit into it very tightly.

He made the same hole in the hairpin.

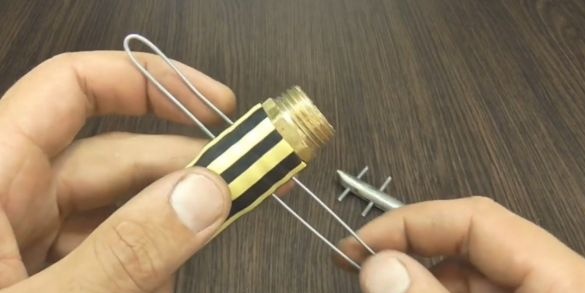

Further, the author pressed one of the cut screws into the hole on the tube

and the second in the hole on the stud, having previously put the tube on it.

I screwed a nut (wing nut) onto the second edge of the stud. This is a ready-made tool for crimping wire clamps.

According to the author, this tool works this way. You need to take the wire into two and wrap it around the junction like this.

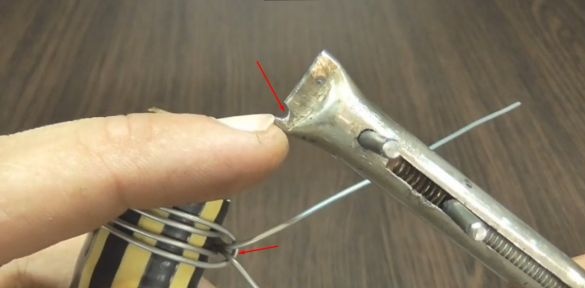

Then, the groove on the instrument must be placed in the loop of the clamp.

wrap the edges of the wire around the rods that are in the stud

Then these edges of the wire must be twisted together.

and then you need to tighten the nut

As you tighten the nut, the wire evenly tightens the hose.

it is clearly visible in the picture

After the author has crimped the clamp well, the tool bends the edges of the wire

loosens the nut and removes the tool from the loop

Bites off the excess wire.

As a result, the author gets an excellent clamp.

Also, according to the author, with this tool it is possible to compress wire clamps of different sizes without any excesses and over-presses.

Video: