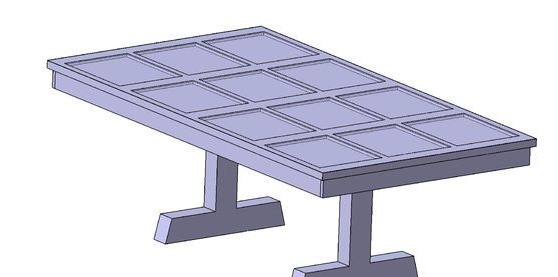

Not so long ago, the author made repairs in his garage and changed the wooden gates to brand new aluminum ones, but I didn’t really want to take out the soundly made doors to the landfill, because the wood was still good and the plywood was special “marine” So the idea came to the master to make a new one a dinner table so that a large and friendly family would gather at it.

Again, a great benefit, turn garbage into sound furniturebut I didn’t really want to buy a new table and spend money.

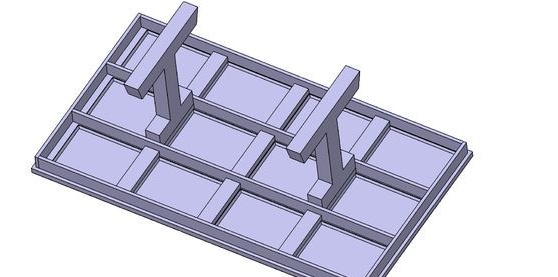

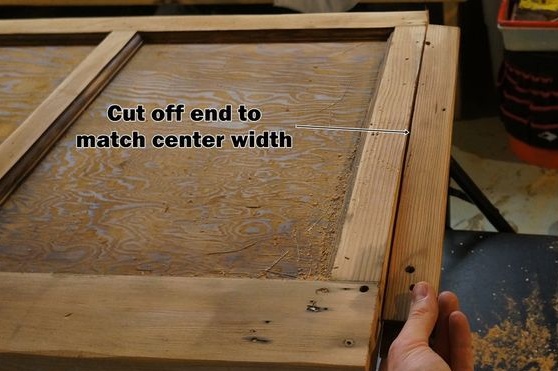

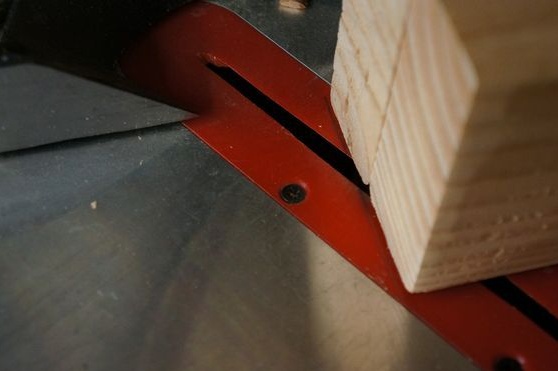

The garage door was in good condition and covered with several layers of white paint, which had to be removed beforehand. Vorotina was transferred to the workshop and laid on a workbench, after which work began on the removal of the old paint coating, it is best to do this with an orbital grinding machine. After the paint is removed, it is necessary to make the base of the table from a thick board or timber. The master made the legs of the table as prefabricated from the board, it turned out very well.

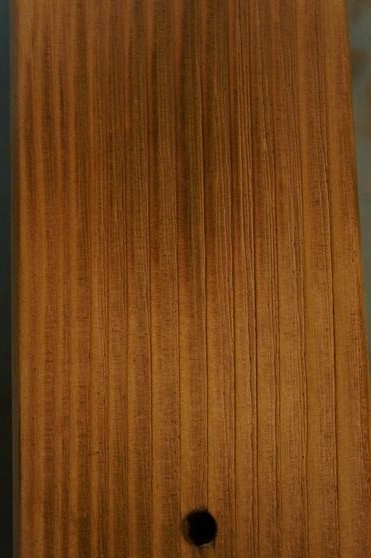

The tabletop should be carefully sanded and coated with epoxy resin, for example, the author took about 6 liters of resin to the entire area of the table, as well as a hardener 10% of the total. Epoxy resin as a material is not quite cheap, but if the rest of the materials were free, then the complex is quite normal. When pouring the resin, you need to be extremely careful and attentive, because the dust or fly that gets into it can freeze and ruin everything. To expel air bubbles from the resin, it is necessary to heat it with a gas burner.

Let's look at what exactly is needed to make a dining table?

Materials

1. garage door (wooden)

2. epoxy resin

3. hardener

4. board 30-40 mm

5. screws

6. stain

Instruments

1. orbital sander

2. drill

3. screwdriver

4. hacksaw

5. brush

6. ruler

7. pencil

8. chisel

9. hammer

Step-by-step instructions for creating a dining table from a garage door do it yourself.

The first thing to do is prepare the door.

Then the surface of the table is covered with epoxy resin with the addition of hardener 10% of the total.

The only thing on the countertop coating was spent a lot of epoxy about 6 liters + hardener. But the result, of course, turned out to be simply incomparable and arouses respect.

As you can see, if you want, you can do everything yourself.

Step-by-step instructions are provided for you, so we take and do it. Go for it friends!

That's all, thank you all for your attention!

Come visit often and do not miss the latest in the world of homemade goods!