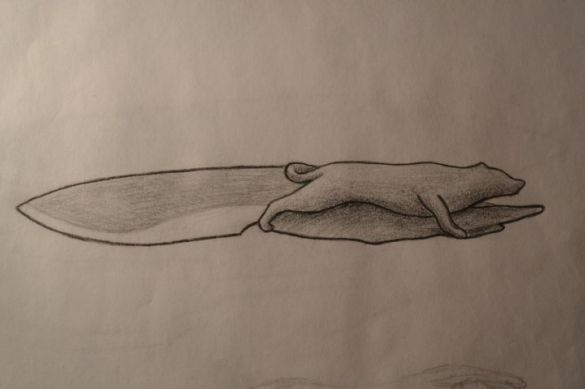

Want to learn how to make cool knives do it yourself? Then take a look at this instruction. Today we will look at how to make a penknife with our own hands. Author homemade He is not a professional in this type of activity, but, nevertheless, he got a good knife.

This knife is made without blacksmithing, the blade is simply cut out by a grinder from a piece of metal. The advantage here is that everything is done simply and it can be done even at home. Well, the lack of strength of steel can be considered a disadvantage, although here it all depends on the workpiece itself and on whether hardening was carried out.

Materials and tools for making a penknife:

- files and files of different grain sizes;

- angle grinder (grinder);

- FeCl will be needed to etch the pattern;

- drill with drills;

- sandpaper;

- a deer horn or other material for making a pen;

- tool of the joiner;

- Red tree;

- a piece of steel for the blade (if you are tempering, choose steel with a high carbon content);

- skin;

- good epoxy glue.

The process of making a knife:

Step one. We form a blade profile

The author makes the blade improvised tools, since he has neither a hearth, nor a belt sander, nor other specialized equipment. Picking up the desired piece of steel plate, he drew on it an approximate profile of the knife and then simply cut it out with a grinder, applying it to a piece of the bar.

Then the task arose to set the bevels on the blade, this is the longest and most difficult event, if you, of course, want your knife to look good. Our master worked with files, a grindstone and a grinder.

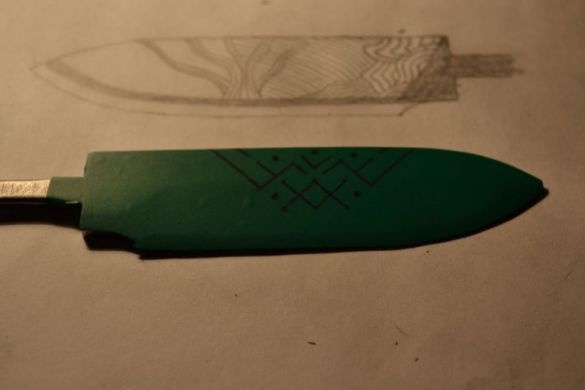

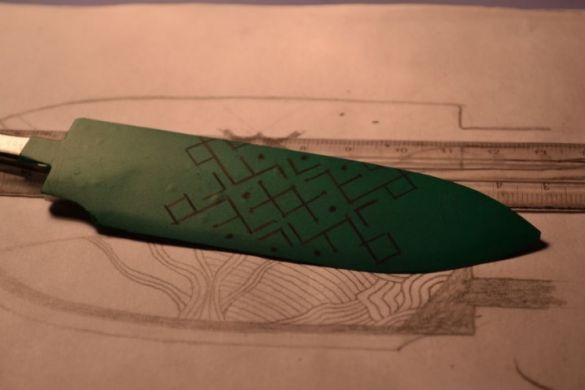

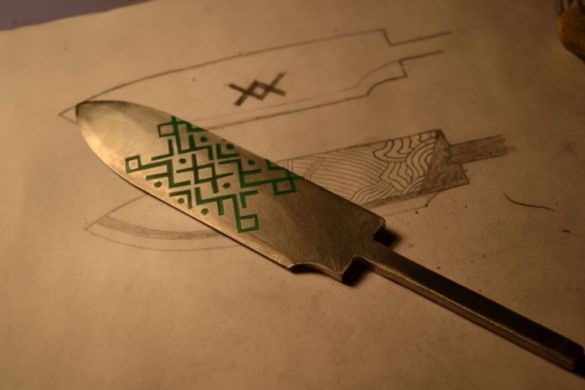

Step Two Drawing on the blade

This step of making a knife is optional, it is needed for those who decide to apply a pattern to the blade. Everything is done by etching, here the author also used a simplified etching method, using available materials.

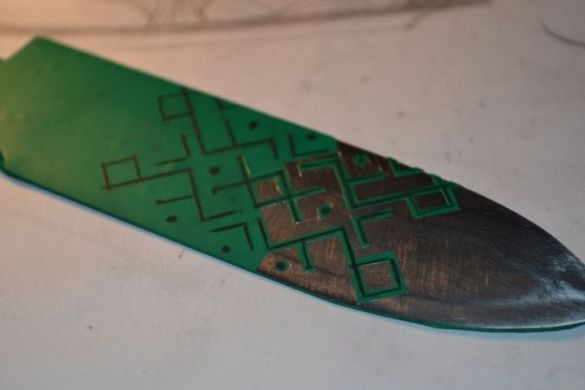

First, the blade was glued with duct tape, and then a pattern was transferred and cut onto it, as the Latvian national ornament was used. Next, the blade is covered with ordinary nail polish and the adhesive tape is removed.

After that, the blade can be covered with mordant, which is iron chloride. After keeping the metal in the reagent for the right time, the blade will then need to be washed and the varnish removed. Still etching drawings can be using electricity.

Step Three Pen making

The pen can be made of various materials, you can use wood, plastic or combinations thereof. The author here decided to use a deer horn. First, you will need to cut a piece that is suitable in shape and size, and then grind it well. If you have a drill or other similar tool, you can engrave the inscription on the handle, depict the animal and other illustrations. The author engraved the silhouette of a deer on a pen.

Under the blade in the handle you will need to drill a hole. Then he will sit on the glue.

Step Four Collect the knife

Now you can connect your hand to the blade. Here you will need an epoxy, such an adhesive is ideal for such work. Just fill it with a hole in the handle and then insert the blade there. The author also carved and installed a mahogany part in front of the handle, which connects the blade to the handle of a deer antler.

Step Five Make the scabbard

Sheath manufacturing begins with design. Everything is done on paper first, and then the desired template is cut out. As a material, you need thick thick skin. We cut out the necessary details according to the template and then punch holes. Further all this business gathers on rivets. The scabbard is also made quite simply and quickly, like the whole homemade product.

Step Six Scabbard styling

To make the sheath more stylish, you can apply a pattern to them. First, you can draw it with a pencil, and then burn it out. A wood burner or a soldering iron with a sharp sting is suitable for burning.

Seventh step. The final stage of assembly

At the end, the author attaches to the pen the rest, which is located at the end of the pen. First, a rough shape is cut out of mahogany, and then glued with epoxy glue. When the glue is completely dry, the handle can be processed. The essence of processing is grinding. It is necessary to smooth out all protruding surfaces, making the wood and horn uniform. This applies to the front and back of the handle.

After final grinding, the knife is usually coated with protective oil. You can use vegetable oils, as well as wax or a combination thereof. You can cover not only the handle, but also the blade so that it does not rust.

As you can see, the knife is assembled quickly, but the author does not temper it at all and does not pay much attention to the choice of steel. So, most likely, the cutting data of such a knife will leave much to be desired. However, this is just an example of making a knife. According to this scheme, you can choose a blank of high-carbon steel, release it and turn the blade. Well, then it can be hardened. The same knife can be considered rather a souvenir.

For hardening, it will be necessary to heat the steel to such a temperature that the magnet ceases to adhere to it, and then cool in vegetable oil. As a rule, after this the metal is still released so that it is not brittle, placing the billet for an hour in an oven with a temperature in the region of 200-210aboutC. It is important not to forget that different grades of steel are hardened at different temperatures and cooled in different substances (oil, water, etc.)