True, at that moment I thought that they were completely out of date, but no, not really.

I worked as an installer in the production of mattresses, in the production of mattresses with an independent spring unit, i.e. each spring is in its own separate pocket.

He twisted in his hands such a defective pocket for the spring.

Knowing the manufacturing technology of such pockets, my knowledge and education, I realized, realized that I was able to create a machine that would be able to produce one pair of the cheapest gloves per second.

It's about what, in order to create a pair of cotton gloves that we still use, it takes some time and an expensive cotton thread. Hundreds of productions in the country, strong competition, expensive exit price - a reality.

In the production of mattresses, we used reels of 285m spanbond material, it is plastic, but the fabric is sprayed randomly and therefore it is cheap and strong, it does not need to be woven, only density plays a role.

Its many types, but in fact this is one, and there are cool colors.

Having wondered, I went through the Internet, they do everything, from shoe covers to clothes and hats, there are no gloves. There are, of course, gloves, but miserable in their handling, primitive, therefore not comfortable, as an example in the photo.

The task was to create disposable gloves that are not a pity to throw out, they are cheap and correctly made anatomically, and you can buy them in packs. So, such a material fit perfectly.

Having spent a month, having studied how to sew gloves altogether, outlining my fingers in one hundred hundred rows, I finally created a pattern, a technologically correct pattern, with seams that can then be welded in exactly this way,

in general, these are subtleties.

The sample is, it must be considered, cut. The patterns turned out, carefully laid out everything, I got an approximate area and calculated that I get 6 pairs of gloves from one meter of fabric of a certain width.

In the 285m video, it weighs 9, let it be a kilogram (I didn’t remember the numbers yet), I found out the price of kg of spanbond in the supply, the wholesale price is natural, but oh well. I won’t tell you the price now, in my opinion it was around $ 1 per kg, then the dollar was worth 30 rubles, but we’ll calculate at the actual rate let 59 rubles, in general we consider: 285 meters / 9 kg = 31 meters in kilogram, 6 meters in pairs, 31 * 6 = 190pairs, i.e. in kilogram 190 pairs.

1 $ = 59r, 59r / 190pairs = 0.31r for one pair of gloves.

We don’t finish the math, but we make a machine, we need to consider productivity. We do not take in excess of indicators, such as work in two shifts and without days off, and so on and so forth, we consider the minimum time, taking into account possible downtime, refueling time, but 12 hours a day, we simply consider that the total operating time is 8 hours (with downtime ), sn at operators is usually piecework, therefore not critical.

Condition 1 pair of gloves per second. I’ll make a digression, from the experience of manufacturing mattresses I realized one simple thing, it doesn’t matter how many stages of production you will do, but if each stage takes no more than a second, then a finished product is output every second, think it over.

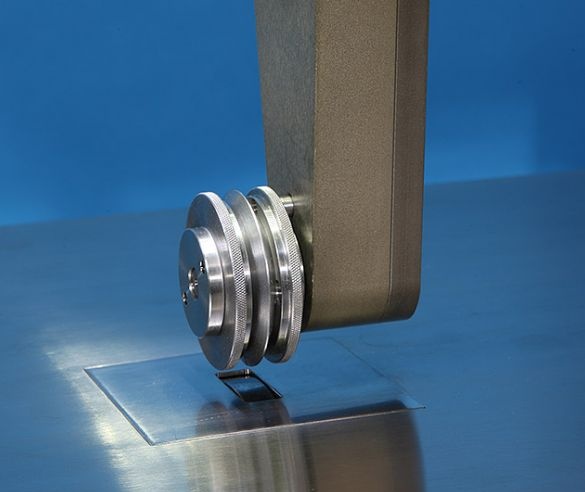

By the way, why exactly one second, is there simply an ultrasonic welding technology (USS), when a high-frequency mechanical signal enters the welding zone, the molecules of two materials are mixed and they become one, by this analogy there are high-frequency current installations, they stretch ceilings and different pvc film, plastic like. You can still thermally fasten it, but it all already lies beyond one second, because you need to take into account the time for heating, cooling.

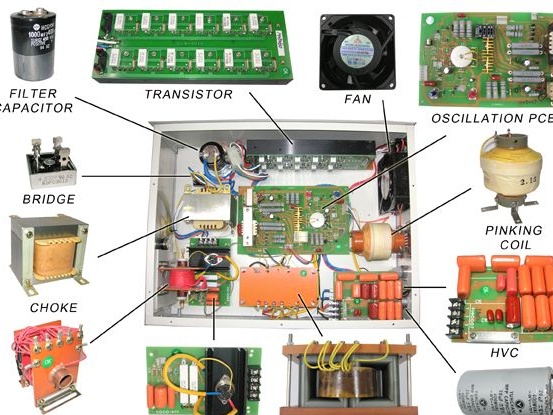

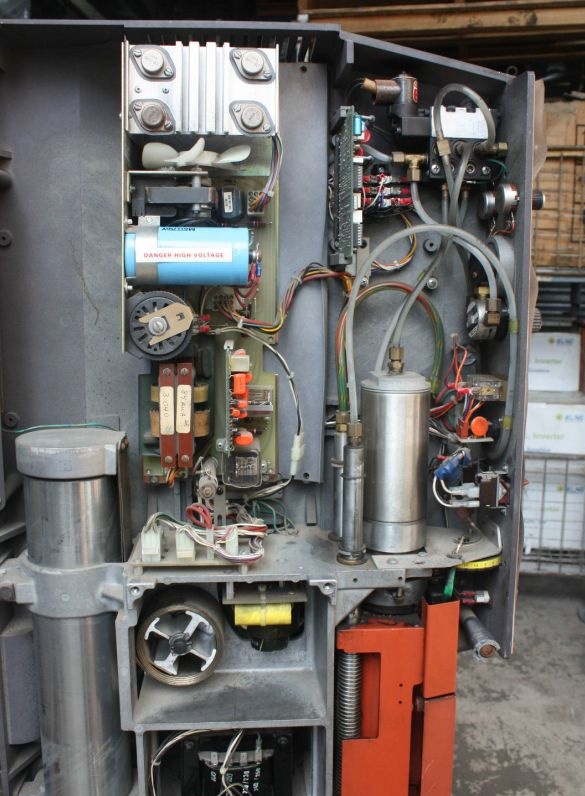

So, it was just with ultrasonic welding that I talked so closely over three years of work that I studied all the sores and types of breakdowns, repair methods, components, settings and everything else.

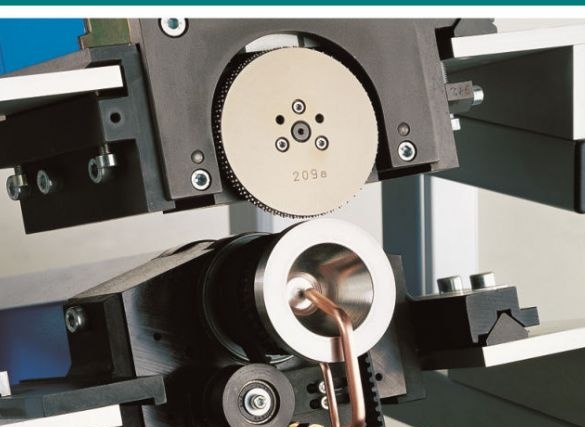

Those. there are two combs, an ultrasonic signal emitter, a high-frequency current comes from the unit, the piezoelectric conductor receiving this current expands for a fraction of an instant and contracts, the comb amplifies this mechanical signal, and the welding itself occurs, for dummies it’s like this, the welding time using technology is about 0, 35sec total, the frequency is approximately 20000Hz (once per second)

So, let's continue the math, at the hour of 3600 seconds, take an eight-hour day (although we work 12), 3600 * 8 = 28800 pairs per shift. In a month, approximately 22 working days (although if there are shifts, then it is possible without intermittent production) * 28800 = 633600 pairs per month from one machine.

Costs: (we do not consider electricity yet, but this is not a little important factor, like sn)

633600 * 0.31р = 196.416rub goes to materials.

Depends on greed of course, but especially new production and in general production is a gain from 300 to 1000% and more probably happens.

We take 1000% - I would take so much, i.e. 0.31 * 10 = 3.10r per pair. I think I could find a sale for that price, I don’t know.

633600 * 3.10 = 1.964.160rub could be obtained, even if the costs of email. energy, materials and spare parts go out in the region of 500tr, profit in the region of 1.5mln rubles per month from one machine alone is obtained !!

When I counted the first time, I thought it seems and could not really sleep)) Okay, and if there are 10 such machines ???

Cool, life was a success and I understand that I really can create such a machine, I really can, it’s very difficult, but possible.

He began to diligently search for materials on welding technology, the possibility of acquisitions, what is on the market, how can all this be applied.

On Ebey I found high-quality European welding systems, boosters, combs, and much more, but not enough information. It is necessary to calculate the power and the combs, and the price, and the possibility of using them on the machine and everything else, time flew for half a year, sat at night, read a lot, the brain just boiled in every sense of the word.

So I found something at a reasonable price, it’s clear that how it was made and what it consists of, you can buy a sample for testing and testing the technology, although in the first sight, everything in general looks like what I worked with before and what I saw.

I began to think about the design of the machine, the task was to make welding of certain seams in some specific planes. The glove conveyed the requirements for such a machine in the best way possible, we must also take into account that everyone's hands are different, they will have to implement sizes.One complication loomed here, since they buy gloves for one at all and do not fool with it, in general, it’s a nuisance, spanbond does not stretch like that, but there are colors! you can make each size out of five or how many of them there (you also needed to understand) to make a certain color and that’s all, you would gradually get used to it and know what is needed already.

By the way, I note that the gloves were so comfortable, that I was able to lift the needle from the table, you see, this is not an unimportant factor, for anatomical gloves that you can easily throw away and in which you can do a lot, the pluses were that they breathe , it’s not latex, of the minuses, it’s plastic, they don’t protect a drop from sparks and very hot over 140g Celsius, but you can order different impregnations, oil or water-repellent when buying rolls with spanbond.

The design seemed like this

They gave a lot to think about, machines for the production of diapers and shoe covers, it turned out they had many moments, but it was not scary, in principle, it was interesting.

By that time I had already replaced my work, but I continued to think and dream, to think where to get the money and all that.

I got acquainted with the system of tenders and public procurements, took part even in these processes. And so, I understood the tragedy of the current situation at government procurement.

Gloves are bought in huge batches only at state orders and other auctions in the auction system, who is cheaper.

The thing is so dreary, waiting for their bidding and we are not talking about millions of couples, the amounts are good of course, but my idea has failed without a clue, you can certainly sell to wholesale stores and all that, but it's not millions of couples, it all became very complicated all of a sudden.

After talking with local manufacturers of gloves, I realized how difficult it was, it would be possible to live, but to earn serious money, it was not that time, not the investments in production, but in the market and sales, certification and everything else would have to be wetted. I realized that this is not my level and I don’t know where to get such acquaintances, who would be able and interested in all this. I left it, a few years passed, I realized that I won’t pull it later, so I decided to share it, just know that there was such a guy who was ambitious, but he didn’t succeed, he will succeed in others, I’ll break through in other directions, and such gloves will still be everywhere, I'm sure of it.

Regards Den_sibirskiy. Good luck, guys))!!