Here's an example of how you can organize your own small knife making business. The topic is quite profitable, as good knives will always be appreciated. The scope of manufacture of knives is also wide, you can make knives for hunting and fishing, for tourism, knives for wood and others are also popular.

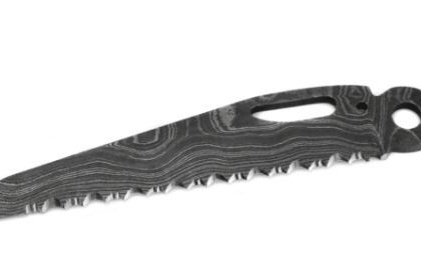

One author automated the process of making knives as much as possible, and he makes knives not simple, they are made of Damascus steel, and besides this, they are also folding. Due to the etching and non-uniformity of the metal, such steel always has its own unique pattern, so despite the serial production, your knife will always be unique.

Materials and tools for making knives

Blanks

To produce such knives, you need Damascus steel. In principle, you can buy ready-made blanks, but of course it will be more profitable to make such steel yourself. Damascus steel is a mixture of different grades of steel. In other words, you can take a pair of plates of different steel, weld the sheets, and then mix by forging. The more layers you have, the more valuable the knife will be.

As for the handles (if the knife is folding), then it is more advisable to buy them. Then, after installing the blade, the knife will be immediately ready. And you can come up with a simple pen design yourself, though the manufacturing process will be delayed.

Cutting tool

The next critical tool will be the cut-off. Of course, everything can be done with a grinder or tape cutting machines, but even this is not very effective. Today, steel is cut with a laser, a jet of water and other tools. This process is almost automated.

Grinding tool

Nevertheless, the production of knives requires some effort on the part of man. The machine will not be able to professionally grind the plane and remove the bevels of the blades. Of course, there is no limit to perfection, but such machines will be quite expensive.

To work, you will need a belt sander.It will allow to qualitatively form bevels, as well as to grind workpieces.

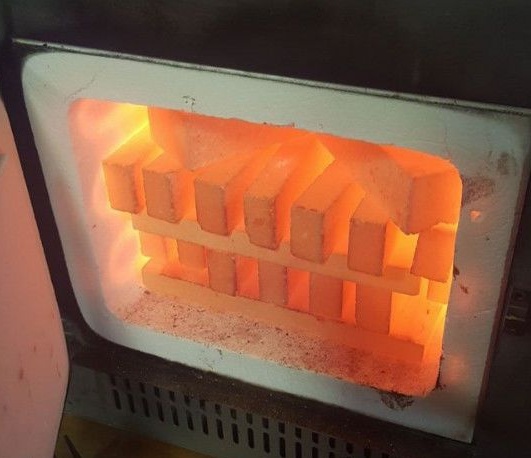

Bake

For hardening knives, you need a good oven in which you can set the temperature and preferably with a timer. This will allow you to load several blanks at once and conduct high-quality heating. Even in the furnace, a vacation is made, for this a temperature of around 200 will be neededaboutFROM.

That's all, actually, I announced the main list of tools. Of course, you will still need hammers, a bunch of different parts for making pens and other parts of a knife, a grinding machine and so on.

The process of making knives:

Step one. Cut the blanks

Having made a damask sheet, the author cuts blanks from it. For maximum ease of manufacture, you can use a water cutter here. How it works can be seen in the video below.

In extreme cases, you can cut it with a band saw for metal, it takes a little time, but it is not particularly difficult.

Step Two Workpiece grinding

Next, you will need human hands and a belt sander. Having screwed the workpiece to the bar, it must be properly sanded on both sides on the machine. You will also need to bring the workpiece to the desired thickness.

You also have to grind the metal in a circle, as after cutting with water there will be some irregularities.

At the end of the work, the author forms bevels on the blade. Here accuracy is important and as a result some experience. The bevels must be symmetrical, even and they are responsible for the future sharpness of the blade.

Step Three Metal quenching and tempering

Here, too, you will need some attention from the person. Steel must be hardened and then released. To do this, we heat the workpiece to such a temperature that the magnet is not attracted to it, and cool it in vegetable oil. In the future, it will not be necessary to set the temperature again, this is done only for the first time.

After hardening, the steel must be released in the required order, otherwise it will be brittle. To do this, you will need a stove with a timer, which is usually set for an hour. Billets are heated at a temperature of 200-210aboutC and cool down as smoothly as possible.

Step Four Carbon removal

After hardening, there will be a lot of carbon deposits on the metal, it can be cleaned manually, on a belt sander, or this process can be fully automated. For such purposes, a vibrating machine with abrasive granules will be needed. You can see in more detail what I'm talking about in the photo. With vibrations, the abrasive granules move and clean the surface of the knives, which are immersed there.

Step Five Etching

The etching process for Damascus steel is very peculiar. Acid “eats” different layers of metal, forming a pattern on the metal that is always unique. Well, everything is simple here, we pour iron chloride into a plastic container and lower the blanks for a given time.

Step Six Sharpen the blade

The next step is to sharpen the blades to a razor condition. For simplicity of this process, the author uses a Japanese water wheel. If you need to sharpen the blade with teeth, then the wheel for toothed blades comes to the rescue.

Seventh step. Quality checking

At the end, the metal of the workpieces is checked for hardness. Well hardened metal should not be taken with a file. The author has a special device that determines the hardness of the workpieces. If everything is fine, you can proceed to the final stage - installing the handle.

The manufacturing process of a handle for a folding knife is not shown, it is quite possible that the author is buying these handles already ready. In principle, you can do them yourself, but then the whole process of making knives will be very long.

After installing the handle, the knife is ready! With proper manufacture, it will be sharp for a long time and will not rust, since the acid has formed a protective patina on the metal.