For work with soft blanks, such as wood, plastic, the Master made a vice. The main advantage of such a vice is wooden sponges that will not damage the product, and a large clamping area of the part. To make a vise, the master used the following

Tools and materials:

- Plywood 355.6 mm X 355.6 mm X 19.05 mm - 2 pcs;

- Board 355.6 mm X 47.62 mm X 19.05 mm - 2 pcs;

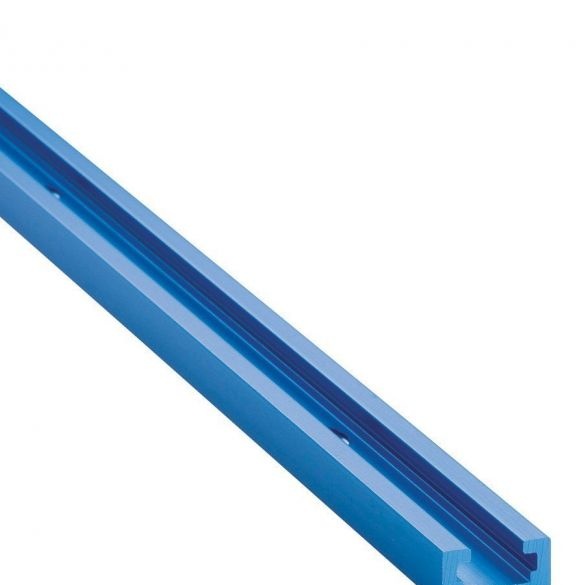

- Guide rail-2 pcs;

-T-bolts -4 pcs;

- Handles round with a carving - 4 pieces;

-Pins long - 2 pcs;

- Curly pens with thread -2 pcs;

- Threaded inserts - 2 pcs;

- Screws - 8 pcs;

-Glue;

-Varnish;

-Roulette;

-Pencil;

- mallet;

-Drilling machine;

- Clips, clamps;

-Milling machine;

-A circular saw;

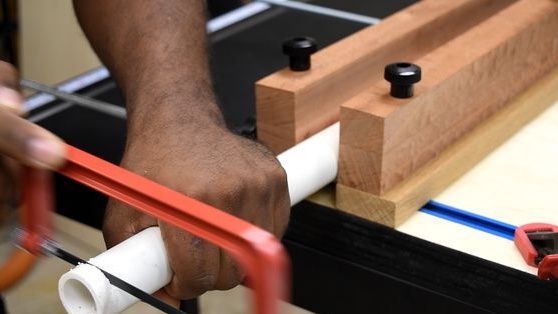

-Saw for metal;

-Sander;

-A screwdriver;

Step One: The Table

The author made a table out of plywood. I cut two plywood blanks (dimensions are indicated in “materials and tools”) and glued them together. Dumbbell master used as a load.

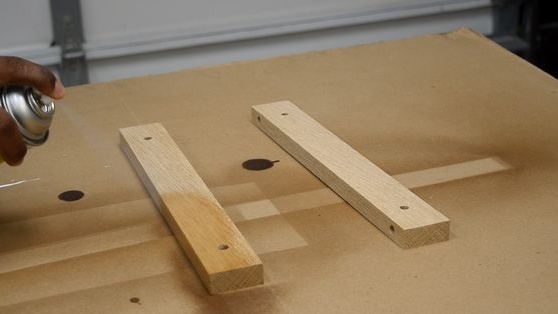

Step Two: Making Sponges

Sponge master made of solid larch. Cut off two blanks. Sponges, on the table, are placed flat. On top of the jaws, it makes a through hole on both sides, under the T-bolts of the guides. Further, in one workpiece from the side, it makes a through hole on each side, under the hairpin. In another workpiece, makes a hole for the threaded insert, not through and through. The holes on both workpieces must be aligned.

Step Three: Guides

The table makes full-length selections. The axial distance between the samples should correspond to the axial distance between the two opposite holes of the jaws.

Fourth step: grinding, varnishing, assembly

Grinds the table and sponges.

Varnishes.

Cuts guides along the length of the table. Sets the guides in the groove and fastens.

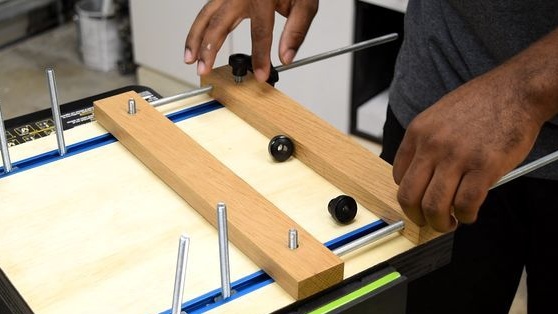

Installs in the guide T-bolts. Installs sponges on the bolts and tightens the handles on top.

Installs threaded inserts, pre-screwing them onto the studs. For durability fixes inserts with glue. The second end of the stud passes into the hole of the second jaw. Screws the handles.

If necessary, you can replace the T-bolts with long ones and install additional jaws.

Examples of use of a vice.

The whole process of making a vice can be seen in the video.