The one who changed the clutch or engine mounts on car with front-wheel drive or subframe, faced with a small problem. Such as hanging an engine. Someone puts the jack under the pallet, someone puts a crowbar on the wings, wrapping it with rags so as not to peel the paint. I went to the auto tool store (taking a tape measure with me). Looked, felt measured the main dimensions of the traverse.

Feet were flimsy. And so as not to remodel after the factory, I decided to do this myself device.

I drove into a hardware store, bought three and a half meters of a 40x20mm profile pipe and hardware. Everything else was at home.

NECESSARY MATERIALS;

1) Profile pipe - 20x40mm - 3.7 meters.

2) Profile pipe - 30x15mm - 0.5 meters.

3) Profile pipe - 20x20mm - 0.08 meters.

4) Four five-millimeter plates - 40x60mm.

5) Steel rod with a diameter of 10mm - 300mm.

6) Rubber (felt) sheet (the thicker the better, but in reasonable

limits) 120x120mm.

Hardware;

1) Bolt M10 L-30mm - 2pcs.

2) M10 nut - 2pcs.

3) M10 washer - 2 pcs.

4) M8 bolt - 4pcs.

5) Washer Grover F 8mm - 4pcs.

6) Nut M8 - 4pcs.

7) M12 L-70mm bolt - 2 pcs.

8) Nut M12 - 2pcs.

9) The washer increased by an internal diameter of 12 mm - 2 pieces.

10) Hairpin M16 - 0.5 meters

11) M16 connecting nut - 1 pc.

12) The washer increased by an internal diameter of 16 mm - 1 piece.

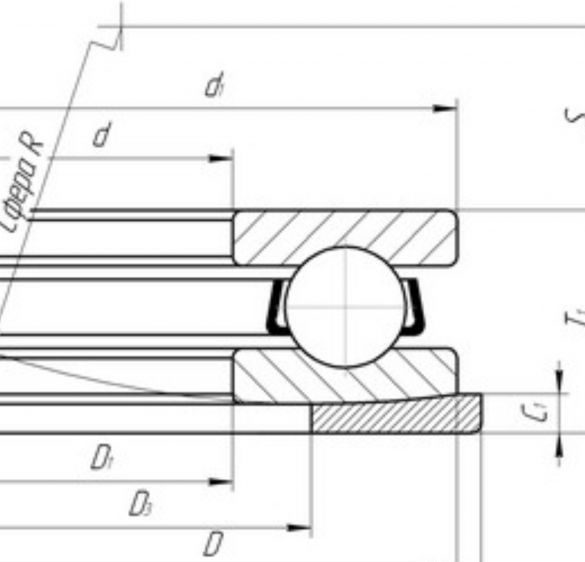

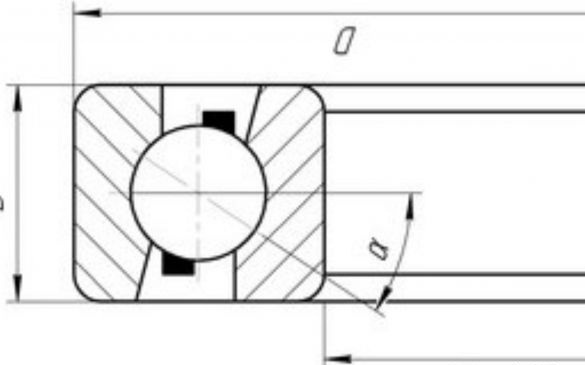

13) Thrust bearing (marking ISO 53203 + U203, GOST 18203)

or angular contact (marking ISO 7203 B, GOST 66203) - 1 pc.

TOOL;

1) MAG welding semiautomatic device.

2) Angle grinder.

3) Drill.

4) Drills with a diameter of 8, 10, 12, 16 millimeters.

5) The square is metalwork.

6) Roulette.

7) Caliper.

8) Yews.

9) Clamps.

10) Keyless pliers.

11) Kern.

MANUFACTURE

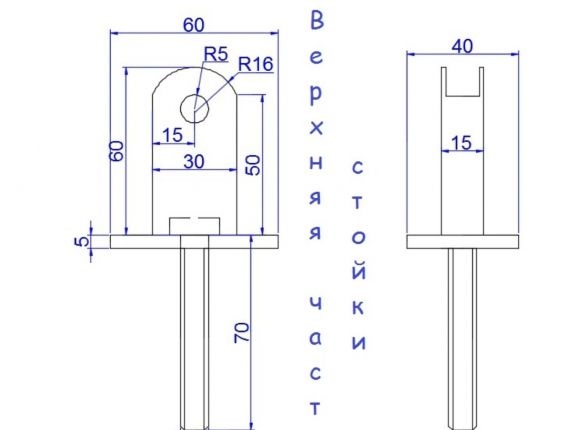

Started by drawing pictures.

FRAME

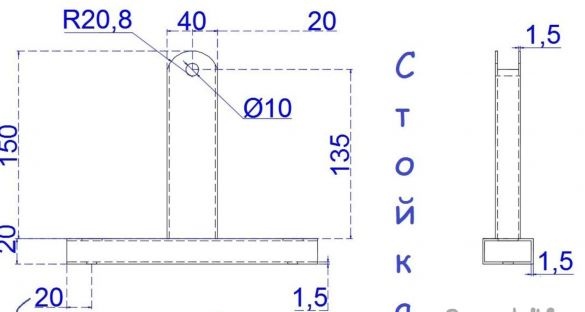

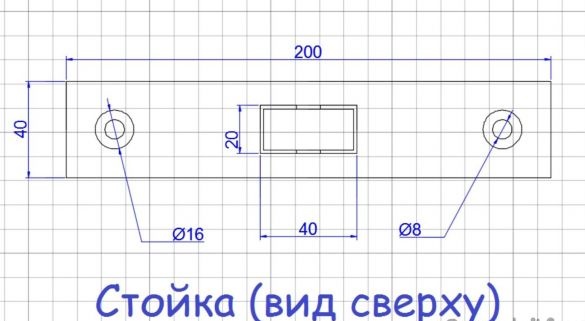

Then he stripped all the necessary metal to a shine (a semiautomatic device does not like dirty iron!). From the profile pipe 20x40mm, the grinder cut two parts of one and a half meters, two parts of 150 millimeters (I had a missing half-meter piece of the same pipe). Marked, drilled, on the blanks of the racks rounded edges. I cut two pieces of 40mm from a 20x20mm pipe.

Having clamped a long pipe in yews, I marked out places for welding amplifiers on it (in increments of 500 mm). Using a square, I set two segments (20x20mm) and fixed them with ticks.

Welded amplifiers.

Observing parallelism and aligning the beginning, I fixed the second pipe on the first with clamps. At the ends of the pipes, to align the gap, put the legs (highlighted in red). Welded amplifiers to the second pipe.

Five-millimeter 40x60mm plates were welded to the ends of the frame.

The frame is ready.

LEGS

The remaining two plates are centered

And drilled

He tightened the connecting nuts onto the coupling bolts (M12), clamped them in a yew and cut off the excess with a grinder.

Having inserted the bolts into the holes of the plates, I fixed them with the same nuts and welded them to the plates.

Processed the seams. The short part of the leg (15x30mm) should be freely put on the seam.

After fitting, I welded the plates to the hinge.

He marked the base of the legs and drilled through with an eight-millimeter drill,

And drilled on one side with a sixteen-millimeter drill.

Then I cut it.

I found in the bins a rubber lining from some industrial equipment. Which I cut into four parts and screwed to the legs.

Here are the legs.

They must be hinged, as the flanging of the wings of the car (gutter, mounting bracket) do not go parallel to the ground but with a slope. The hook should be located perpendicular to the surface so that it is not bent by the weight of the engine.

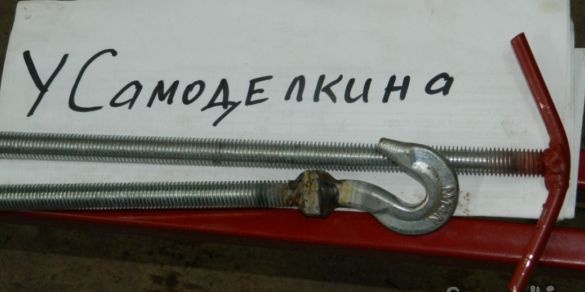

Hook made from M16 studs. Just by welding a ten-millimeter bent rod to the end. The second of the lanyard hook replacing the torn thread.

The nut with handles rests on an angular contact bearing to facilitate chain tensioning.

Ready-made universal crosshead

The M16 construction stud is enough for any motor (no heavier than 500 kg). Since it only supports the engine while the car is working on removing the gearbox, replacing the engine mounts, replacing or extracting the side members and the like. Another engine is used to remove the engine. For example a crane, hoist or winch.