If the apocalypse suddenly comes, and even worse, if it is the zombie apocalypse that our American brethren are afraid of, we will have to take care of two main places - this is protection and food extraction. As it’s not difficult to guess, for all these purposes we will need weapons.

Of course, everything described above is a joke and we will not collect a military crossbow, we will only make a great toy for children that will allow you to plunge into this very atmosphere of the apocalypse and feel like a hero. However, the crossbow will be interesting for adults, it will be nice to shoot from it at nature on targets.

Materials and tools for homemade:

- glue for wood;

- a couple of boards;

- washers, screws, nuts and other little things;

- spanners;

- epoxy or superglue;

- a piece of PVC pipe for the manufacture of the spring (and other accessories);

- building hair dryer;

- rope for making a bowstring;

- dremel, a tool for cutting wood;

- sandpaper;

- wooden rods for making arrows and more.

Crossbow manufacturing process:

Step one. We cut the wooden part of the crossbow

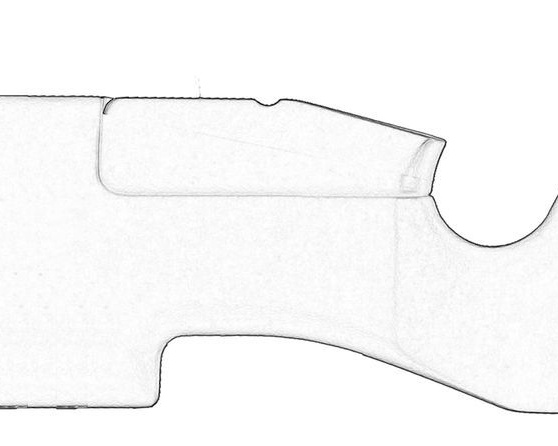

The author makes the crossbow case made of wood, which served as two boards. First you need to print a template on the printer, and then cut it with scissors. You can create a template yourself if you are strong in this type of activity.

Next, you will have to try a little to cut the blanks, which we should have two pieces, and both halves should be completely identical. If you have a jigsaw, grinder, or other similar tool, you can connect the two boards, and then immediately cut and form two workpieces. Manually, of course, this will be difficult.

Having cut a rough profile, we take a file and we remove all unnecessary. If you fit two halves to each other, they can be glued together. Epoxy glue is best suited for such purposes. Clamp the workpiece with a clamp and let the glue dry completely. Then, after a day (usually the epoxy glue dries as much) we take a file and finally fit both halves to each other. At this stage, the work of the eye can be considered completed.

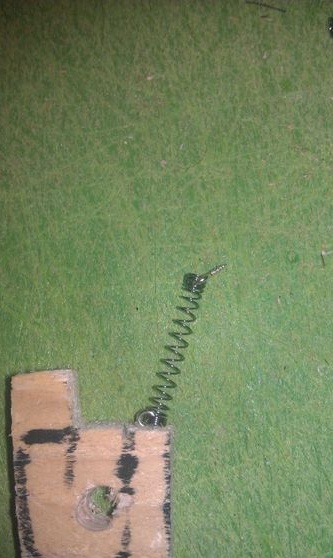

Step Two Crossbow spring manufacturing

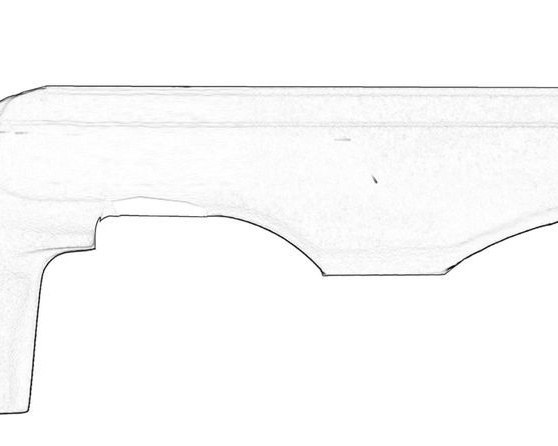

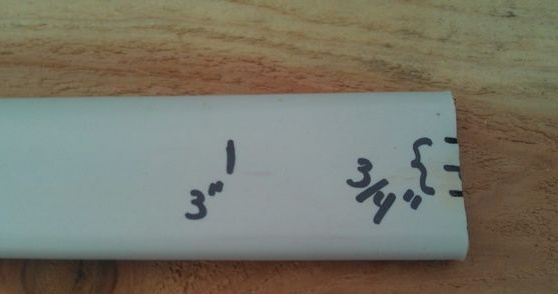

The author uses a PVC pipe as a spring. Here you can select the desired pipe diameter and length, thereby adjusting the power of the gun. The thicker the pipe and the longer it will be, the more powerful the crossbow will be.

In some such homemade products, the authors simply attach the pipe to a crossbow, in the same pipe is made flat, and then a special profile is also created.

The first step is to make the pipe flat. To do this, it can be heated with a construction hairdryer, the plastic will become soft. The heated pipe can be clamped between the boards or come up with some kind of clamping device.

After that, you can make a spring profile. Here you also have to be smart and make a mold. We heat the pipe, place it in a mold and wait until the plastic cools down.

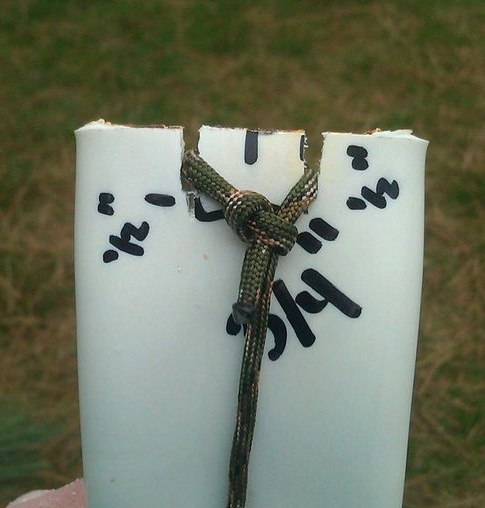

Well, now it remains to install a crossbow string. For such purposes, you will need a strong rope, the author uses a paracord. We drill holes at the ends of the spring and tie the rope as in the photo.

The spring itself must be securely fixed on the crossbow. To do this, drill a hole in it in the center and screw a good self-tapping screw, and preferably two, if there is enough space. It is also possible to additionally fix the spring with epoxy glue.

The author fastens the spring by tying it to the mounted pins.

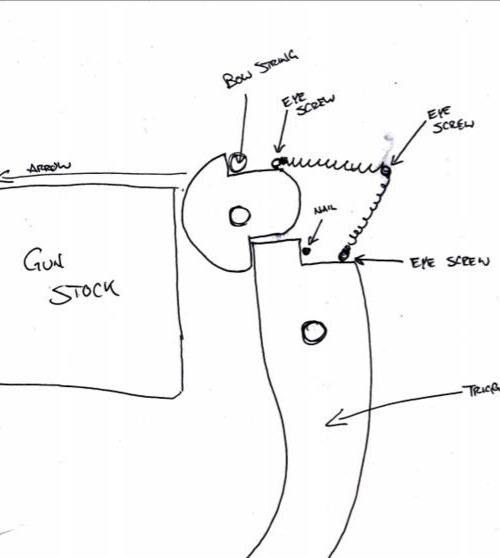

Step Three Crossbow trigger system

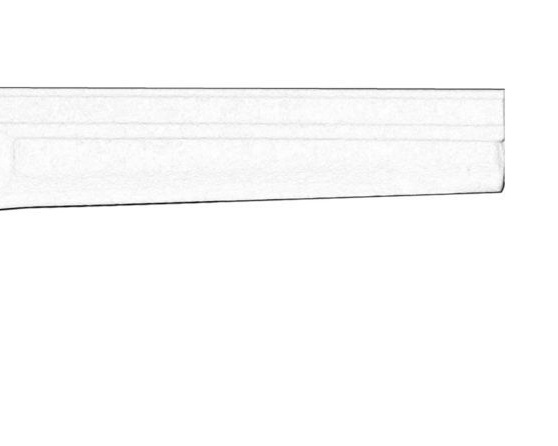

Crossbow shot by pulling the trigger. The homemade product is certainly cool, but here you have to tinker most. However, everything is perfectly visible on the diagram how everything is arranged. You will need two steel washers, they will need to grind as you see in the photo. This piece will hold the string in one piece. And the other part of it will rest on the trigger. When you pull the trigger, the part will rotate and release the string. You will also need two springs.

The author makes the trigger of wood. Then, parts of washers made earlier are attached to it at the top of the sides. To assemble the entire trigger system, the author needed two screws with nuts.

Step Four Arrow making

The author makes arrows from wooden rods, their length is about 20 cm. The arrow tip is metal, he makes from washers. We set the puck to the desired shape and install it on the rod, for this we make a cut in it and sit the tip on epoxy glue.

From the opposite part of the boom you need to make plumage for stabilization, it can be made from real bird feathers, for example, a goose, a dove, and so on.

Another feature of this homemade can be considered a system for fixing arrows. Thanks to it, you can lower the crossbow with the loaded arrow down, and the arrow will not fall out. To make such a latch, find two toothbrushes and a piece of PVC pipe. In the pipe, make one longitudinal section, and then heat with a hot air gun. Next, form parts from plastic, as seen in the photo. They need to drill two holes for mounting to a crossbow. Then cut off the tips of the toothbrushes and glue them to the brackets made. Well, now both parts need to be mounted on a crossbow so that they clamp and hold the arrow well.

Step Five Crossbow Tests

Never shoot a crossbow at animals and people, at least alive;) Despite the fact that this is a toy, it can cause serious injuries, and even kill in some circumstances. Also, do not test weapons near cars, especially expensive ones, otherwise they may kill you.

For a shot cock a spring and establish an arrow. The trigger is fired. Good luck and take care of yourself.