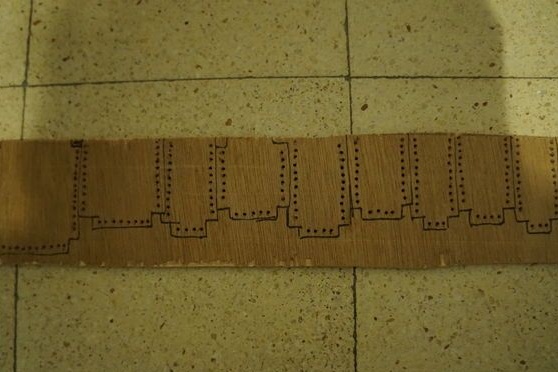

This box is made for convenient storage of the tool, as well as all kinds of useful trifles, nuts, screws, bolts, nails, rivets and much more) Inside the box is divided into separate sections, which allows you to accurately separate the types of fasteners, when doing work it is very convenient when everything lies in its own place.

Under the tool, the author made leather pockets, pre-cut blanks from genuine leather, made holes at the edges to later sew a pocket with a square blank from plywood that will be glued to carpentry glue or PVA.

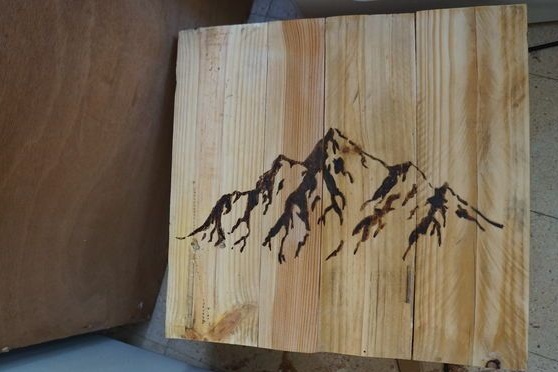

The main material for creating a tool box is a regular pallet pre-disassembled into separate boards. All the charm is that pallets are a free source of boards from which you can do anything. The body and cover are made of boards, the bottom of plywood with a glued fabric. The lid is set on furniture hinges for easy opening and closing. On its surface, the author also burned out a beautiful drawing in the form of mountains, with the help of a burner. If desired, you can cover the box with varnish or stain to give the tree a more aesthetic appearance, as well as varnished wood will last much longer. In the corners, the master made leather corners, first soaked in water and pulled the damp skin on the corners, after it had dried and acquired the necessary shape, the author cut out wavy edges and glued the elements to the box.

And so, let's look at what exactly will be needed to assemble a wooden box?

Materials

1. pallet

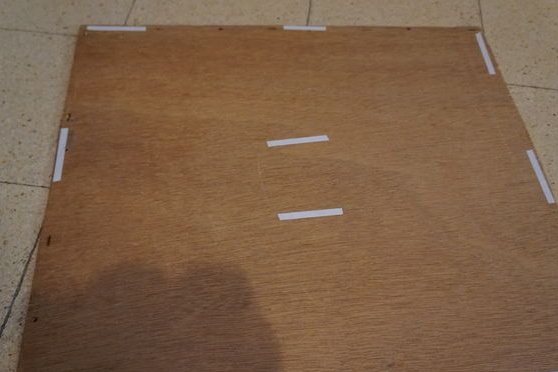

2. plywood

3. cloth

4. leather

5. wood glue or PVA

6. screws

7. riveting

Instruments

1. hacksaw

2. Planer

3. drill

4. screwdriver

5. orbital sander

6. brush

Step-by-step instructions for creating a wooden tool box from a pallet do it yourself.

Pallets are a source of free boards of different types of wood that are used by enterprising people in different areas: they build fences, make furniture, dishes, and also build cottages and household construction. In this case, the pallet was disassembled into planks in order to make a convenient and unique tool box.

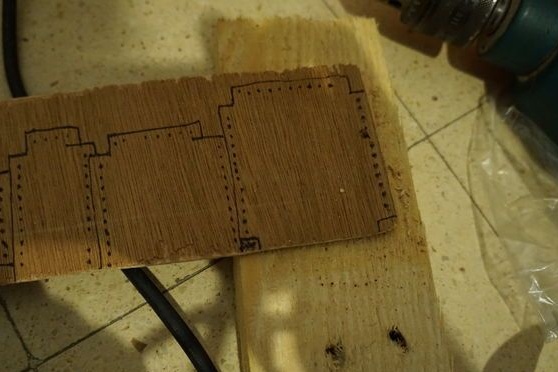

Also, the author prepared all the necessary tools: jigsaw, orbital sander, burner, etc.

That's all, thank you all for your attention!

Come visit often and do not miss the latest in the world of homemade goods!