Going on a trip around his native land, a relative expressed a desire to have a compact mini-stove on a trip in order to minimize dependence on circumstances. At the same time, he outlined a compact and economical device seen somewhere, called the “Bond stove”.

To this request, the Internet issued information.

The Bond stove or a turbo stove is a marching mini-supercharged stove with a fan on a small motor powered by batteries.

The design of the stove is double-walled. This helps to enrich the furnace of the furnace with air and at the same time cool the outer casing of the furnace. In this case, it is possible to achieve a more complete combustion of the fuel under the influence of an elevated temperature, due to the forced flow of oxygen into the furnace zone.

The furnace can operate both in the boost mode using a fan, and in the standard “grate” mode with natural traction and variable combustion mode. First, such a stove burns like a flame. As the fuel burns and its load settles, the role of complete afterburning of fuel from heated air and an increase in the efficiency of the stove are enhanced.

Turbine oven has its advantages.

This is light weight and volume occupied in a backpack. The fuel for this stove is chips, small twigs, cones - that can be found underfoot. Thanks to the boost, even wet wood burns well. If for ordinary cooking at the stake large firewood is needed, then the turbine stove eats up any trifle, the deficit of which should not be anywhere. At a load of 2-3 dozens of pine cones, you can cook dinner for 2-3 people, and in winter (at minus 100C) you can boil 0.5 liters of water for 20 ... 25 minutes.

From the considered material options for manufacturing the working part of the furnace, the design was selected from stainless steel mugs made in India, which are available in stores in the city under the code 555. The mugs are sold in a set of 7 pieces of different diameters (from 70 to 130 mm) or separately.

Such a design will have a longer service life, a better look and will not corrode, will be as economical as possible in terms of material costs.

The use of canned foods is marked as a one-time use.

To make this option, a mini oven will need:

- 1 mug of stainless steel with a diameter of 120 mm.

- 1 mug of stainless steel with a diameter of 100 mm.

- 1 mug of stainless steel with a diameter of 70 mm or a tin can of condensed milk (diameter 73 mm, length 75 mm).

- A motor with a supply voltage of 3 volts.

- 2 AAA pinky batteries and a box for their installation.

For the manufacture of a combustion chamber, we use a mug of a smaller diameter (100 mm). Separate the handle. In the upper part of the circle, at a distance of 20 mm from the edge, mark out evenly around the circumference and drill 16 holes with a diameter of 8 mm. First, we drill with a smaller drill, and then in size, since the stainless steel is drilled rather poorly with ordinary drills. These openings are necessary for heated air to enter the combustion zone.

Turn the mug over and uniformly in area, mark and drill in the bottom, openings for air to enter the combustion zone. In this embodiment, 13 holes with a diameter of 5 mm were made (do not pay attention to the large taper in the photo, this is an optical illusion that is created when you try to take an object close and on both sides).

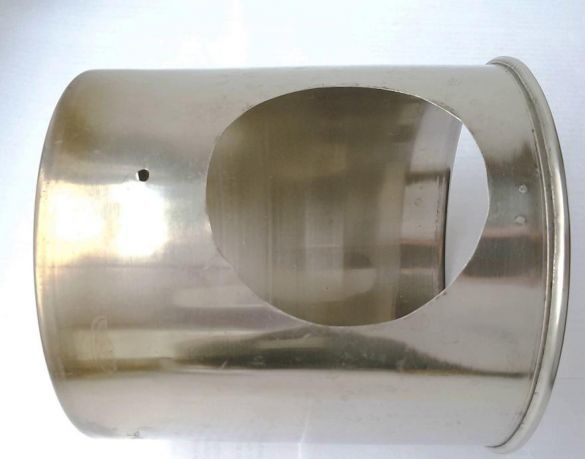

We proceed to the manufacture of the case from a larger diameter mug. Separate the handle. We need to cut a hole in the bottom of the cup-case for installing the cup-combustion chamber. Since these mugs are made by rolling, they have a slight taper. The diameter of the hole being machined in the bottom is determined by measuring the diameter of the inside of the cup under the whisk (it differs from the diameter at the bottom). It is important to cut the diameter in the bottom very carefully so that the combustion chamber sits tightly to the rim. Therefore, the marking of the diameter is best done on paper glued to the bottom.

It is easier to start the processing of the diameter by drilling, inside the diameter, a series of consecutive holes with a small drill (noticeably on the cut out part of the bottom). Then cut the hole with a jigsaw and adjust the size with a file. When fitting, we periodically check the density of the combustion chamber in the housing.

The next step will be to cut a hole for boost, on the side of the mug. Its size should be 3 ... 6 mm less than the diameter of the housing for the boost module.

To ensure that the hole is neat and does not interfere with the air flow, it is necessary to mark it along the counterpart - the housing for the boost module. Therefore, in advance we will prepare a blank for this case.

make a can of condensed milk.

Cut the remaining bottom (it is useful to us for the manufacture of the fan impeller) leaving a sealed edge to strengthen the body.

Then, on the other hand, we need to make a curved neckline so that the jar fits snugly against the body of the stove, without leaving large gaps. To make such a neat cutout is quite difficult. Therefore, we pre-mark with a felt-tip pen and cut off the excess, and then gradually remove the metal with scissors, applying it to the stove “for fitting”.

Fastening the boost module to the furnace body can be done as you wish. In our version, we will drill a hole in the jar at a distance of 10 mm from the edge of the machined contour and fasten the L-shaped strip of stainless steel (from waste) with a screw.

In the bent part of the strip, we will drill a hole and modify it for installing the M4 screw with a groove (keyhole). With its help, the boost module is mounted on a pin in the furnace body.

For the exact manufacture of the pressurization hole on the side of the furnace body, mark it with the manufactured body for the pressurization module. We attach it tightly to the furnace body at a distance of 20 mm from the base and draw a felt-tip pen around the inner contour. Then, retreating into the marking contour by 1.5 ... 2 mm, mark and cut the hole according to the previously developed technology. We blunt sharp edges.

We apply the blank of the boost module housing coaxially to the manufactured hole and outline the place for installing the fastening pin on the furnace body. We drill a hole with a diameter of 4.2 mm.

In the hole, with two nuts, we fix the M4 screw, leaving a place under the head for installing the mounting plate of the boost module.

.

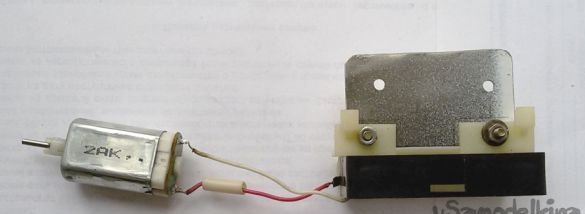

The motor for the fan is removed from the old computer drive (you can use any with a supply voltage of 3 volts, for example, from a children's toy). On the motor shaft there is a half-coupling with a groove, which we will further use to install the fan impeller.

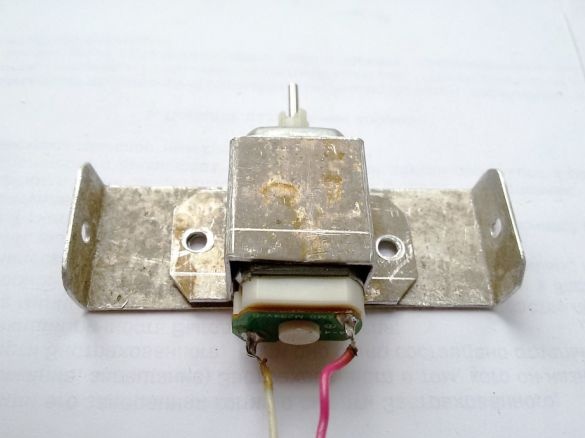

To power the motor, you need two AAA batteries (mini-finger). We select a box for them and solder it to the motor. We manufacture and fasten with screws to the box a rectangular adapter plate.

To mount the motor, cut out two strips of sheet aluminum, form, as shown in the photo, drill the mounting holes.

We make the impeller of the fan from the cut out bottom of the can. In the center of the workpiece, we drill a hole for the selected diameter of the blind rivet, insert and upset it, drill a hole in the rivet for the diameter of the motor shaft. Coaxial holes reduce the outer diameter of the workpiece by 2-3 mm relative to the diameter of the housing. We cut and bend the impeller blades.

On the reverse side, we cut off the upset part of the rivet to the size of the groove in the coupling half on the motor shaft.

We assemble all the parts of the boost module drive.

We place the assembled assembly in the housing, mark out and drill mounting holes.

We assemble the boost module.

looks like that.

In a stowed position, all elements compactly gather together.

Shipping dimensions (without stand):

- diameter - 124 mm, height - 133 mm.

- the total weight of the stove and batteries is 340 grams.

Photo from the test mini-oven.

During operation, it is important to remember that in simple combustion mode, the fan must be removed from the stove to prevent overheating of the engine.