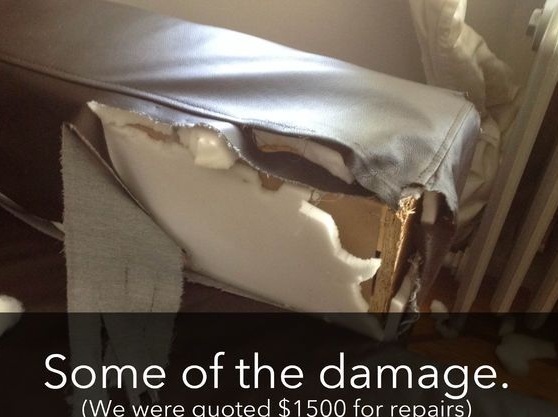

The author of this homemade there was a problem, his dog was constantly chewing on a wooden furniture in the house, in the end it was decided to make it out of metal. Metal square pipes were used as the basis for home-made work; everything is assembled fairly quickly, most importantly, correctly cut all the necessary details in accordance with the scheme.

Materials and tools for homemade:

Material List:

- plywood;

- square pipes;

- paint;

- bolts with nuts;

- screws for wood;

- steel corner.

Tool List:

- drill;

- welding with all accessories;

- Bulgarian with cutting and grinding discs;

- protective equipment (glasses, gloves, etc.)

Sofa manufacturing process:

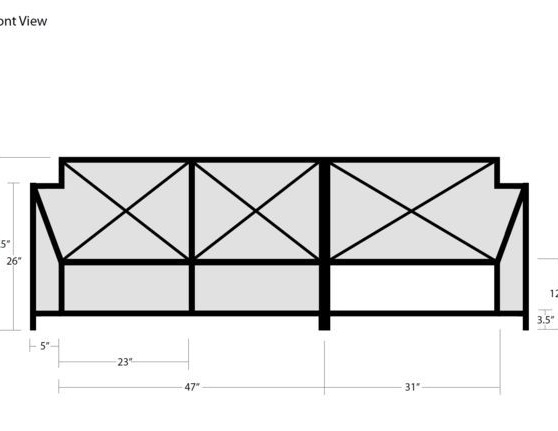

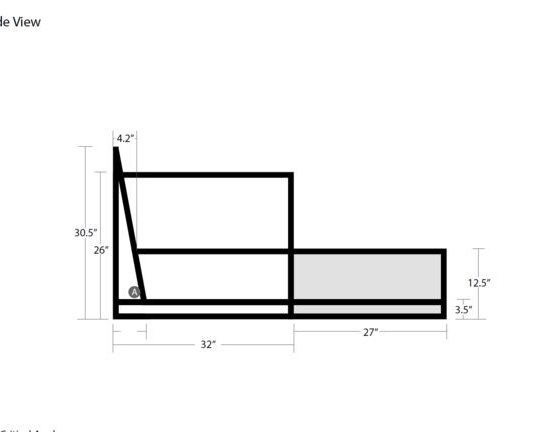

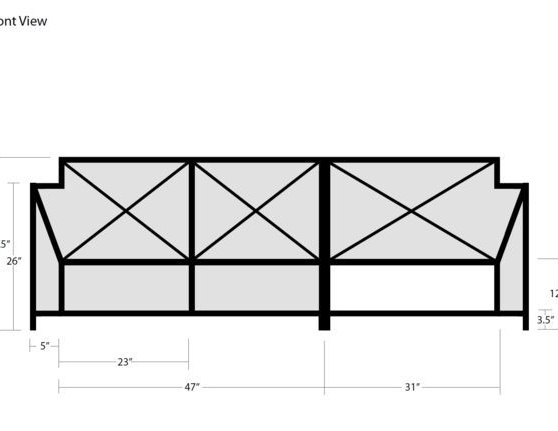

Step one. Sofa layout

First of all, you have to make a diagram of how the sofa should be, the author used the Sketchup program for these purposes. You need to proceed from the needs, as well as from the size of your sofa cushions.

Step Two Cutting workpieces

Having decided on the size of the sofa, we cut according to the drawing all the necessary blanks. For cutting metal pipes, you can use a circular saw with a disc for metal. In extreme cases, you can work with an ordinary grinder. Try to keep the corners smooth, grind the notches immediately with a grinder. In order not to get confused later, immediately sign all the components with a marker.

Step Three Weld the frame

At this step, the author welds all the details into a single design. In this case, the main thing is not to rush, accuracy is very important here. Use a ruler, clamps, preferably magnetic locks to securely fix parts before welding. When heated, the metal is deformed. So first you need to weld pointwise and only making sure that everything is smooth, weld completely.

When welding, in addition to the mask, be sure to wear long-sleeved clothing and pants, as you can get ultraviolet burns.

Step Four Grinding joints

To make the design look like a whole, you need to grind the welds.For such purposes, a grinder with a grinding disc is suitable. Work slowly, take care of your eyes and ears. Do not overwork, take breaks. This work is long and tiring, but it is within the power of man.

If the seams do not turn out homogeneous, all defects can always be hidden with putty, the main thing is that everything is tight.

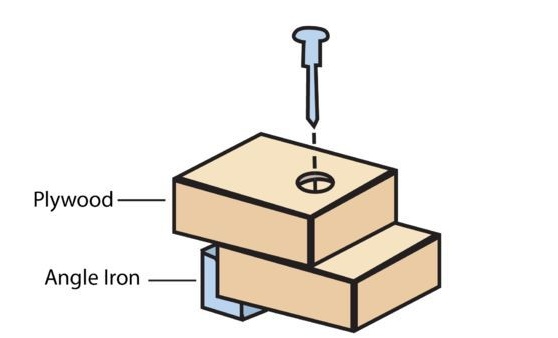

Step Five Weld brackets

To attach plywood to the sofa, you need to install brackets. The author makes them from a steel corner, welding to predetermined places. Seams after welding will also need to be sanded with a grinder. In the same step, drill holes for the screws that will hold the plywood.

In addition, drill holes for the legs of the sofa. The author makes the legs out of bolts with a nut. This makes it possible to adjust the sofa so that it does not stagger. This is a topical issue for a home where the curve is gender.

Step Six Plywood preparation

You have to cut out all the necessary blanks from plywood. Next, we thoroughly grind the parts so that they are smooth and the edges have no burrs. The plywood is attached to the sofa so that it is inside the steel corner. As a result, the pet can no longer damage the tree.

After machining the blanks, take a paint or stain and paint the plywood. In the end, the author covers it with a layer of varnish. As a result, the furniture looks stylish and is not ashamed to put it at home.

Seventh step. Paint the metal frame

Now you can paint the frame, for such purposes you need paint on metal. It is better to first coat the metal with soil. First, carefully sand the surface of the entire frame in order to clean off rust and other contaminants from it. Finally, wipe the frame with a rag dipped in acetone to remove any grease from the surface.

What color to paint the frame, you decide. The author decided to paint it black first, but he did not like this option. As a result, it was repainted in dark brown. It is convenient to paint with cans.

Step Eight. Putting up a sofa

To assemble the sofa, you need to fix the plywood, and put pillows on it. To fix the plywood, we take the screws on the tree and screw them into the holes drilled in the corner. At the same stage, we insert the screws with nuts into their places, which allow you to adjust the sofa for stability.

In the end, you only have to install pillows from the old sofa. That's all, the homemade product is ready. The sofa turned out to be strong and, most importantly, pets cannot handle. Of course, it is not very suitable for a residential building, however, it can be trimmed. But put such furniture in the garage, workshop or in the country is very good.

With ready-made drawings and the availability of materials, everything is assembled quickly, although the author took a whole year to assemble it from scratch.