In this article I want to talk about the different types of covers and hatches in aircraft models (and not only in aircraft), as well as about the methods and mechanisms for securing them.

I have used all kinds of locks repeatedly, but each one is good in its own way, and is used depending on the type and weight of the model.

Under each of the types, its pros and cons will be written so that it is more convenient to choose and compare them among themselves.

Materials:

- rubber bands for money

- bolts and nuts

- strong neodymium magnets or badge magnets

- wooden ruler

- bamboo skewers

- spring from a ballpoint pen

- threads

- self-tapping screws

- Velcro from clothing or equipment

- plastic cards

- steel wire

- other materials of which the corresponding model

Instruments:

- screwdrivers

- jigsaw

- cutter

- adhesives (PVA, epoxy)

- clothespins, clips

- scissors

- pliers

- thermal gun

- other tools with which to create a model

1. Covers on an elastic band.

:

+ Easy to manufacture

+ Cheap

+ Versatility

+ Quick opening lids

:

- Elastics lose elasticity in the cold

- Poor for copies and half-copies

The easiest and most popular way to fix the hatch on an aircraft model. Its essence is that the lid is attracted with the help of one or more elastic bands to the fuselage of the model. You can use it on any model trainer with a wingspan from half a meter to two meters.

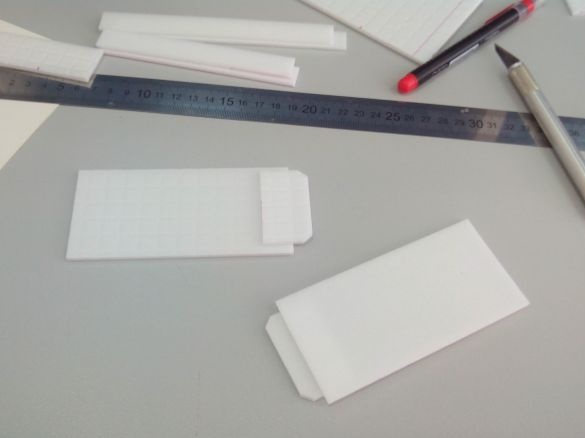

For this, it is only necessary to cut out the hatch itself in the fuselage.

Glue a bamboo skewer under it or a little to the side, having previously strengthened its gluing places with additional layers of a ceiling or other material.

In the hatch, make a small handle from a paper clip or wire so that the elastic does not come off and the lid can be easily opened.

Now we insert the cover into place and pull the elastic.

But it is worth noting that this option is more applicable in the warm season, in the cold the gum may burst, which will lead to loss of cover or even e stuffing model. Although used in snowmobiles.

And on aircraft models in the winter too.

2. Covers on bolts.

:

+ More aesthetic appearance (good for half copies)

+ Reliability

:

- In the field you will need an additional tool

- Quick opening

A less common option for attaching covers, but one of the most reliable. Well suited for small aerobatic models and large models.

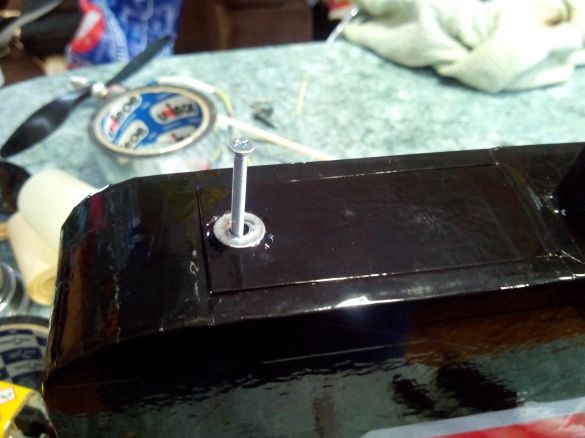

To make a cover on bolts, it is necessary to fix the cover itself pivotally (for example, on strips of adhesive tape)

Glue the nut into the fuselage on the epoxy adhesive and make a hole for the bolt in the hatch cover.

As a variation - glue the wooden lugs, and screw the lid with a small screw.

To slightly reduce the opening time of the lid, you can take a bolt with a large head or make it yourself to unscrew it without tools. Otherwise, each battery replacement will occur with a screwdriver.

3. Covers on magnets.

:

+ Aesthetics (suitable for copy models)

+ Quick opening lids

+ Reliability

:

- Rarer materials

- Purchase of neodymium magnets

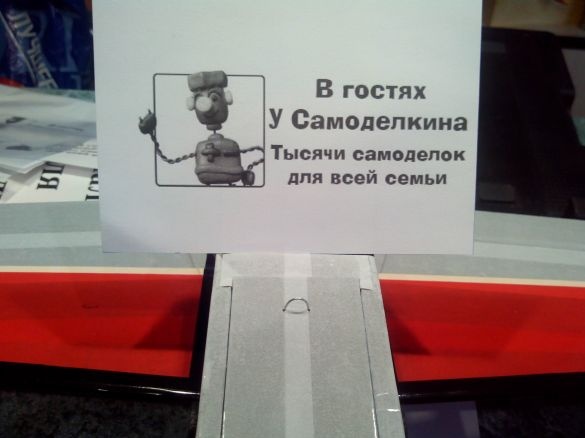

With the development of online commerce and commerce in general, this method of attaching covers is becoming one of the most popular. Because the model with such a cover fastener looks better, and the speed and convenience of closing the lid is the highest.

For the manufacture you will need strong neodymium magnets or magnets from name tags.

Depending on the strength of the magnet and the need, you can glue a small plate of metal in the fuselage, and a magnet in the lid, or glue both the lid and the magnet in the fuselage to hold the lid better.

For bonding, you need to use five-minute epoxy glue or cyacrine (relevant for wooden models).

In terms of ordering neodymium magnets via the Internet, there are also comments. It is not recommended to order these magnets together with the electronics in one package, so as not to damage this very electronics.

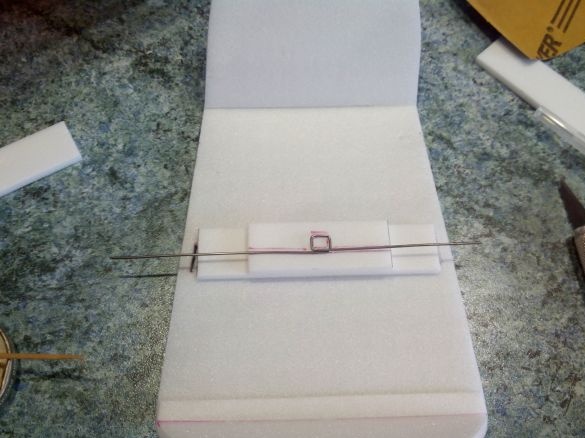

4. Covers on latches.

:

+ Simple materials

+ Reliability

+ Durability

:

- More production time

- May spoil the appearance of the model

This type of lock is one of the longest to manufacture (unless of course you buy a ready-made latch in a specialized store).

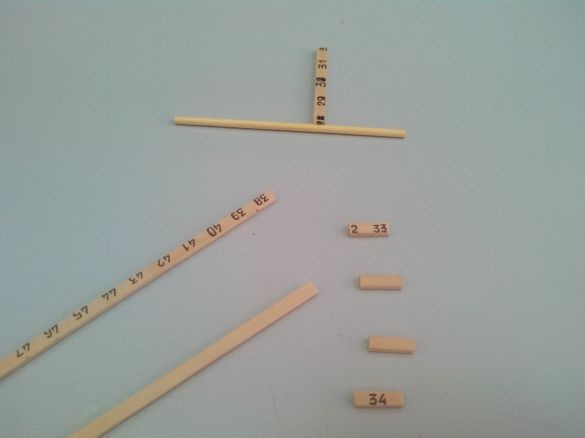

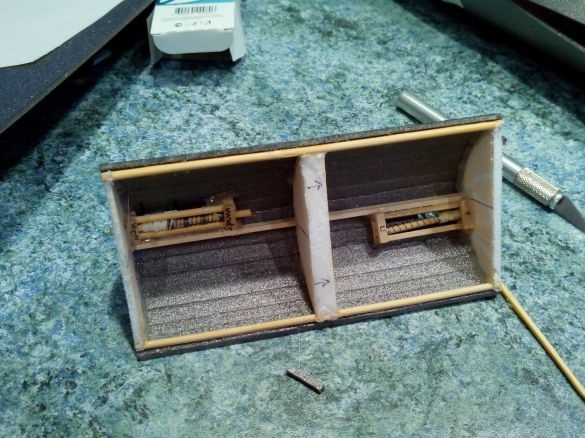

For its manufacture, we need thin slats or a piece of a wooden ruler, from which the frame of the latch is glued.

Then, from the bamboo skewer and thin rack, the latch itself is glued.

All parts are best glued with PVA glue. The junction of the rail and bamboo should be reinforced with glue.

Then we put the spring from the handle on the latch, insert it into the frame and glue the rest.

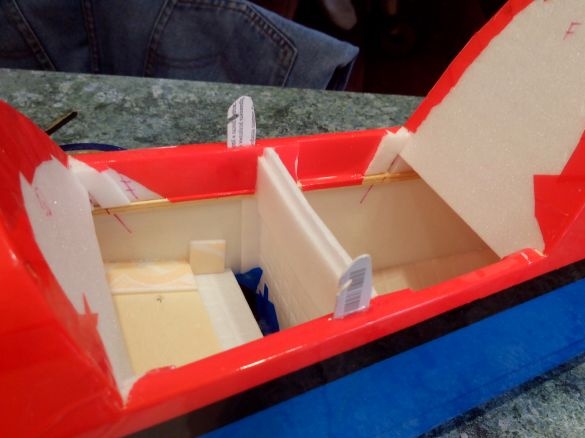

We paste the finished latch into the manhole cover with hot-melt adhesive, making a pre-cut under the handle.

Option with two latches without a hatch hinge.

If necessary, we make holes for the latch in the walls of the hatch and reinforce the hole with a wire clip.

A couple more options for covers with a latch.

The convenience of such latches is undoubted: they are easy to make from improvised materials, they are light and fit well on many models. In addition, if the model accidentally breaks, such a latch is easy to rearrange to another model. But sometimes they can spoil the look of the model.

5. Covers on "flypapers".

:

+ Good appearance

+ Quick opening lids

:

- Not always there are "Velcro"

- Not every glue can withstand the load.

- Not applicable in every model

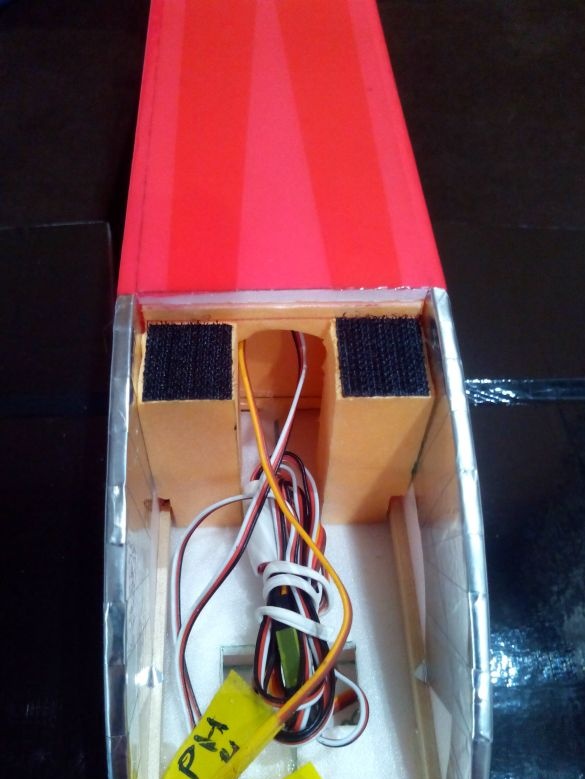

In boxes with USB modems, for example, there are little-used Velcro fasteners that can be glued to the lid and inside the fuselage.

It is better to glue it on epoxy glue or with super-glue so that with multiple openings of the hatch, do not tear off the “Velcro” itself.

This mounting method is rare for the most part, not even because of the rarity of the Velcro itself, but because of the impossibility of gluing the second half of the Velcro into the fuselage - there’s no need for anything.

Of all my models, there is only one that attaches the cover to Velcro, as there was a place in the fuselage for gluing two foam-plastic blocks to which the second halves of the Velcro are glued

6. Covers on hooks.

:

+ Good appearance

+ Quick opening lids

:

- Not applicable in every model

- Long production time

This type of mount is popular on large balsa models. In small models it is rarely used.

Hooks can be made of plastic or thin plywood.

We paste the hooks into the fuselage on epoxy glue.

Glue a piece of steel wire or a thin carbon fiber rod to the lid.

In the lantern we make slots for the ends of the wire.

When closing the lid, the wire should cling to hooks on both sides.

This method is well suited for large models that are done slowly, for a long time and in the presence of certain tools and materials. Of course, you can make a lid on the hooks and on a simple trainer or aerobatic meter-long model, but such models usually do not last long, especially if they are models of a beginner aircraft modeller.

There is another option when the hooks are located in the lid itself, and the wire holder in the fuselage, but the essence does not change from this.