Another homemade from AlexGyver, a four-blade boomerang from improvised means. Almost anyone can make such a boomerang, the materials used in homemade products are available to everyone. This boomerang starts working immediately after assembly, if you follow all the recommendations and instructions, and minor improvements that will be discussed will help improve its performance.

So, for the manufacture of a four-blade boomerang, the author used the following materials:

- Two slats, length 30 cm, width 4 cm, thickness about 7 mm.

- PVA glue on wood or liquid nails

- Auxiliary tools - file, hacksaw, knife and sandpaper

Boomerang Making

First you need to prepare the material, for this you need to cut the slats of the right size and process them well with sandpaper. The author recommends not using too dry a tree, as the heavier it is, the better the boomerang will fly.

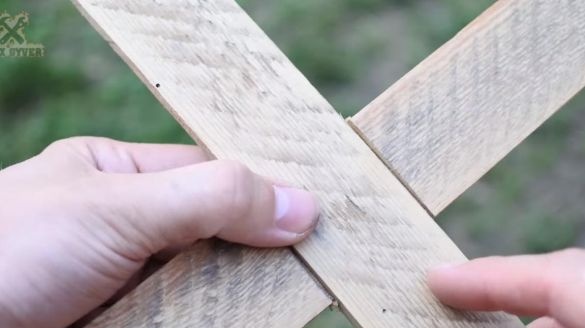

After preparing the material, you need to mark the workpiece. They will be fastened to each other cross to cross, with which they need to be fixed in one plane, for this it is necessary to make grooves in the center of the rails so that one goes into another. We mark the slats as shown in the photo below, the sizes are arbitrary, the marking from the end must be equal to half the thickness of the slats.

The next step is to make cuts with a hacksaw for metal in the marking places, cuts must be done on the front side of the rail to the middle, this must be done with two blanks.

Next, with a knife, carefully remove the middle part, clean the remaining chips with the same knife.

After all the manipulations, both planks should ideally fit into each other, forming a solid and smooth surface. Using a file, you can adjust the grooves for maximum joint accuracy.

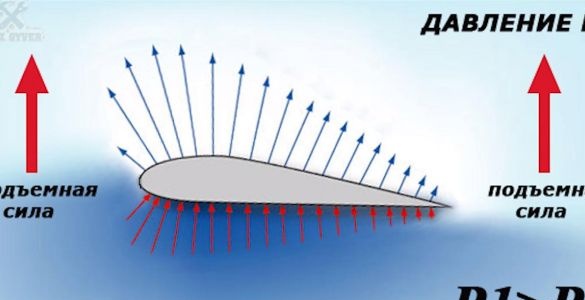

The next shalom you need to give each blade the shape of a wing, in order for the design to work. The diagram is shown in the figures below.

To do this, use a pencil to shade from the middle of each blade in a circle, according to this marking, you will need to use a knife to make oblique sections. What should turn out, see the photo below.

Using a rough file, we process the places of cuts, removing all irregularities and dimples.

After rough processing we take sandpaper and clean all the edges of the boomerang until the entire surface is smooth and even. It is also necessary to round off all the edges.

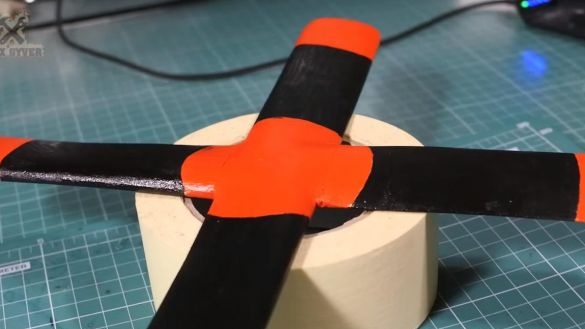

Next, we take PVA glue or liquid nails, apply it to both parts of the groove, smear it and glue it together. In order for the two halves to stick together perfectly, it is necessary to clamp the gluing place using a clamp or press. Leave it to dry according to the instructions, you can even a little more, that would be for sure.

After gluing the surfaces, it is necessary to remove the glue that has come out with sandpaper and finally process the finished boomerang, giving it a beautiful look.

In principle, the boomerang is ready and you can experience it. After the tests, the author thought that the boomerang is not gaining waxing enough, and this affects the accuracy of the return flight. To fix this problem, the author decided to weight the boomerang. To do this, he drilled a hole at the edges of each blade and put fishing lead loads in these holes.

All irregularities at the holes, it is also necessary to clean with sandpaper and pour liquid nails. After the nails have dried, you need to polish the excess with sandpaper.

After a little refinement, the boomerang rotation frequency increased and it began to fly more quickly and more accurately. In order to protect the surface of the boomerang from any pests and the adverse effects of the environment, you can paint it with paints and thereby give it a beautiful look. And after applying the paint, the boomerang will become even heavier, which will favorably affect its characteristics.

That's all, the boomerang is ready for operation. If everything is done correctly, then such boomerangs work in 95% of cases. Watch homemade video at the end of the article.