Hello. In my previous publication, I talked about manufacturing hard disk squares. Then I took apart a lot of hard drives

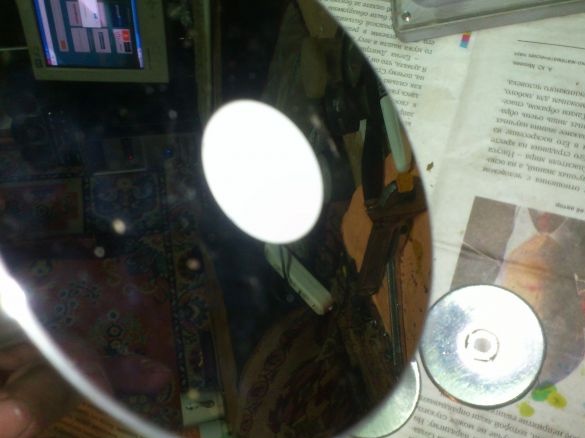

Inside, as you know, in addition to neodymium magnets, there are also carriers in the form of metal disks:

Throw out discs hand did not rise. )))). Made of polished metal, judging by the melodic ringing - quite hard. (click with a finger on the edge in a suspended state))). The metal is not black (check with a magnet), i.e., most likely, it will not give in to corrosion.

And I decided to make one of them a pizza knife.

My daughter often cooks this dish. You cannot cut it with an ordinary knife - the knife pulls the melted cheese adhering to it. Circular knives available for sale are generally not of very good quality, or quite expensive. So I decided to make a solid strong disk knife by making a cutting disk from the hard drive's hard drive. The thought seemed interesting to me ...

Looking ahead, I’ll say that I was sure that it was I who came up with such an idea! )))). And only now, by publishing an article, and clicking the "find similar" button, I saw that even on this site there is such a homemade

I don't want to say anything bad about this homemadebut it doesn’t suit me, because, for practicality, the knife should have the following properties:

1. Do not have wooden parts! (Fat + wood + water is not a good combination))))))

2. Do not have "complex shapes". (Must be easy to wash!)

3. Be strong!

4. Be sharp !!! (The edge of the disc is rounded!)

I made a knife. For this I needed:

1. Actually the hard disk itself (media).

2. Scraps of sheet "stainless steel" 1 mm thick.

3. Cutting of sheet "stainless steel", 2 mm thick (for side overlays on a disk)

4. The chromeplated "railing" metal tube.

5. A piece of hairpin M10.

6. Disposable large size syringe.

7. Stainless steel hardware. (Bolt M6 by 70. M6 self-locking nuts - 2 pcs. M6 cap nuts -2 pcs. M10 nut - 1 pc. M10 cap nut - 1 pc.

First of all, I decided to try to sharpen the disk ... (It can be ... and it would be even easier to do it at a later stage. But I wanted to “see the product face” and understand whether it should be used as a cutting element at all.

For uniform sharpening, it is necessary to sharpen it with a rotating one. I have several emery made from small motors, I decided to install a disk on one of them. Having carefully examined it and measured it, I found out that the inner hole has a diameter of 25 millimeters:

My stanchok landing "grinder" - 22.2mm. Since the speed will not be very large, I decided to make a ring of wire that compensates for the difference in diameters:

On a landing washer I put a paper pad:

O put on a wire ring disc:

I decided to sharpen the disk with the usual bar:

So, the disk is ground. Next, I began to think about how to make the hub! Do not put the disc on an axis 25mm thick!

Also, like the author of a similar homemade product, there was an idea to somehow use the hard drive engine - after all, there is already a landing! But, having examined and thought, I threw it away. I decided to just fill the inner hole with something, and make two side washers-lining of stainless steel. Looking for something suitable, my gaze came across such a disposable syringe:

He interested me in the fact that the upper platform of the piston has the diameter I need:

I decided to use it. Without hesitation, I sawed off the site with a grinder (this, of course, is from the category of “from guns on sparrows”!)))). A clerical knife would have been enough! But the grinder was at hand, and behind the knife I had to unbend))))):

After that I drilled a hole with a diameter of 6 mm in the center. (Fortunately, after cutting the piston, a crosshair remained on the mug, which accurately indicates the center.):

Now you need to make the side washers overlays. Since, as I said, my knife must be resistant to corrosion, I decided to make them out of stainless steel. I found a suitable piece in my scrap metal, I drew two circles of a suitable diameter and cut them out with a grinder:

Putting them together, I drilled a hole in the center with a 6 mm drill. (When working with stainless steel, you need to use cobalt drills, and drill at low speeds, cooling the drill)

After that, I pulled them off with an M6 bolt and a nut:

Now you can clamp the bolt into the drill chuck, and rotating the workpieces, give them a perfectly round shape on the emery:

Then, more subtly, on a diamond cup:

And remove the burrs and strip on the emery-petal circle:

Lining ready. You can assemble our "hub":

(It is precisely at this stage that it is easier to sharpen the disk! You can simply clamp it into a drill, as I clamped the washers, and grind it, bringing it to emery, for example.)

Now we will do the mounting of the disk. Having rummaged in scrap metal, I found another piece of stainless steel, this time thinner - about one millimeter (I don’t know what it was, he got to me with a cut piece)))):

Having marked it, I cut a strip from it, 20 mm wide:

And he bent the U-shaped bracket out of it, drilling holes in it under it for the axis:

This will be the disk holder. Now you need to make a defense. I cut out another strip, making two such slits in it:

Putting them together, I drilled a hole with a diameter of 10 mm at the intersection. (Unfortunately, I forgot to photograph this process. But then everything will become clear.

After that, with the help of a grinder and an emery-petal wheel, I rounded all the corners on the parts and removed all the burrs.

And he polished it all on a felt polishing wheel using GOI paste:

I decided to make the handle out of the trimmed chrome railing tube:

I cut off a suitable piece from it ... I can’t say the exact length .... I was guided by the concept of "so that it was normal!"

But the chrome tube is just the decor! The bearing function will be performed by the M10 pin located inside. I cut a piece of hairpin 10 millimeters longer than the length of the tube:

For assembly, I bought stainless steel hardware in a hardware store.

After all, in the kitchen, all tools are exposed to moisture, acids and alkalis (detergents). In addition, it is not always possible to wipe dry - there are also inaccessible places. Therefore, all metal parts, as far as possible, should be made of stainless steel.In my design, the exception is only the carrying pin of the handle - it is ordinary, galvanized. But it is inside, and I carefully decorated the only unprotected end face from the spray can with silver enamel in several layers.

So, let's start assembling ... The handle from the bottom will be attached to the structure with the M 10 nut. To reduce the clearance between the guard and the disc, I decided to make the nut lower. To do this, I screwed the nut onto the hairpin a few turns, carefully locked it in with the second nut, and cut off the protruding part:

All! We collect. Bottom - trimmed nut, cap will be on top:

I assembled the axial assembly as follows: I used a stainless M6 bolt as an axis, from which I cut the hat:

the disc linings squeezed by self-locking nuts. I chose this type of nuts not because of their inherent ability to turn away tightly (although this doesn’t hurt)), but because their outer side has a round profile, not a faceted one. Indeed, in my design, the disk will rotate along with the axis, and it will be the nuts that will rub against the bracket. (I didn’t want to use the washers, so as not to create an extra "hard to clean" place)

inserting the axis into the holes in the bracket, I fixed it on both sides with cap nuts.

The clamping force was adjusted by the length of the axis - the cap nuts rest against the end of the axis with caps, and even a very strong tightening of the nuts will not interfere with the easy rotation of the axis. In order to prevent the nuts from unscrewing spontaneously, you can, in addition to tightening, use thread sealant, or a drop of glue:

That's all, actually! A circular knife is ready to cut pizza)))

Using a similar technology, you can make a multi-disc knife for cutting dough (manufacturing home noodles). Since I disassembled many Winchesters, I still have many disks ... (In some, after all, there are two of them) ... Maybe I’ll do it later, after asking my women if they need it and whether it will be in demand ...

... For now, I won’t be interested ... And then, they’ll suddenly say "Needed !!! Do it !!"