If you live in a country house or go to the country, you often miss a good strong knife in your life that can cut, cut everything and do not worry that the knife will be damaged. Today we look at how you can do it yourself make just such a knife.

You have ample opportunities in choosing the material and tools for making such a knife. The main blow should be made on the quality of steel, it should be as durable as possible. The best and most affordable steel is tool steel. The simplest example is an unnecessary rasp.

As for the tools, you can do with the most minimal set. It would be nice to have a belt sander, but not everyone has one. To replace him without a problem, and grinder.

Materials and tools for homemade:

- sandpaper (small and large);

- grinder ();

- belt grinding machine ();

- a source of metal for a blade;

- wood for the handle;

- hammer;

- a burner or other heat source;

- vise;

- epoxy adhesive;

- the drill () will not hurt.

The process of making a knife:

Step one. We form a blade

First of all, we make a blade. We need to form bevels depending on domestic needs. The author makes bevels on both sides of the blade, and also sharpens the tip of the knife. As a result, we get two blades. You can make one thin, it can be conveniently cut. And the second blade can be made as thick as possible so that something can be cut with a knife.

Bevels can be formed using a grinder or files. If you work with hand tools, it is advisable to "let go" of the metal so that it becomes soft. To do this, heat the workpiece and let cool in air.

If you use the file as a workpiece, you can then not heat it, just let it go in the oven, heated to a temperature of 200oC. We put the metal there for an hour and then let it cool smoothly. As a result, you will get a great durable metal for a knife.

If you decide to harden steel, heat the workpiece in coals to such a temperature that the permanent magnet ceases to be attracted to it, and then cool in oil. It will only be possible to harden a metal if it has a sufficient amount of carbon. Usually with tool steels there are no problems. After hardening, be sure to leave the metal in the oven, otherwise it will be too fragile and the knife can easily fly apart when dropped.

Step Two Make a pen

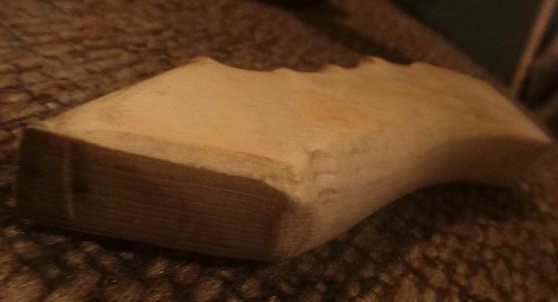

The author makes a pen in a very simple and understandable way, although this method is not very reliable. The handle is cut out of wood. Find a suitable material and cut out a handle that is convenient for you in shape. It will be convenient to do this with a jigsaw.

Having cut the rough form, we bring it to the ideal. Using rasps, sandpaper and other devices we bring the workpiece to the desired shape. It should get smooth edges and become smooth. The author makes a pen from a public pine board.

Step Three Collect a knife

Now the knife can be assembled. To do this, the author heats the shank of the blade with a burner, and then he burns a hole in the handle. Next, the tail part is lubricated with epoxy glue and installed in its place.

But this is not a very wise decision, because after heating the metal will become soft and your blade will simply bend at a certain point at the point where it joins the handle. Do not be too lazy to drill a hole in the handle and then glue the shank. However, if there is no drill at hand, you can burn it only with another metal object.

Step Four Completion

The knife is ready! Sharpen the blade properly. In the end, do not forget to protect the handle from water and dirt, because this is a knife for domestic purposes. You can use paint or varnish, but a more professional approach is to use flaxseed oil for impregnation.