If you are actively storing firewood for the winter, you will need a good ax. One author decided to make an effective hatchet for himself, which splits firewood into 4 parts at once. In the end, you need to hit the log only once to cut it into pieces suitable for the firebox. True, with such an hatchet, it will probably be harder to chop pads with knots and so on, and pulling out in case of something will be problematic.

An ax is made (easily, in fact, it is assembled from two axes.

Materials and tools for homemade:

- two axes;

- grinder ();

- welding ();

- sandpaper;

- a little strength and patience.

Getting to the ax:

Step one. We prepare the blades

You will need two axes, or rather two of its metal parts, which are called blades, blades and so on. They need to be cleaned of rust, remove wooden handles and so on.

Next, take one ax and cut it lengthwise into two parts. It will take a long time to cut, because the metal is thick and the steel is durable. But do not overheat the metal at the same time, as it may temper and the steel becomes soft. True, it can be hardened. The author also cuts off the back of two halves. We carefully process the workpieces with a grinder or other methods so that there are no problems during welding. Try all the parts together so that they fit snugly. Sorry, the blank should have approximately the same shape as the author.

Step Two Welding

Now you have to weld two workpieces to the main ax. First grab the spot parts and make sure they are secured evenly. Well, then we carefully weld the parts from all sides, and wherever possible. The loads here are considerable, so everything should be held tight. When the metal cools down, beat the slag and make sure that the seams are made with high quality. If there are sinks, boil in this place yet.

Step Three Grinding Tools

After welding, the author carefully polishes the welds and the entire product as a whole. As a result, he gets a monolithic design.

Step Four Polishing

Performing this step is not necessary, it is rather a way to surprise a neighbor, however, the eye rejoices at the very same person. We take sandpaper and carefully grind the entire surface. If desired, it can be made mirror.

Step Five Completion of work

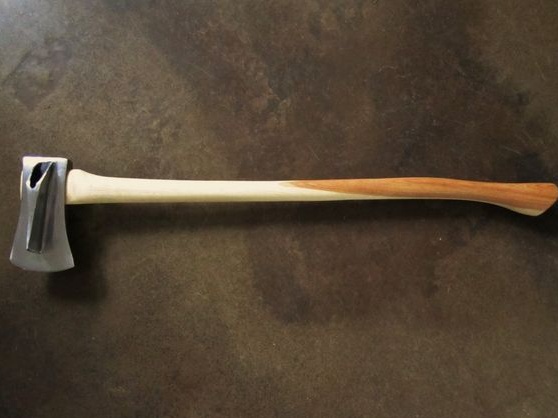

Now we just have to fix the ax well and the ax can be considered finished. You still need to soak the handle with oil or protect it in another way from moisture and dirt. The author used olive oil for such purposes, but in general it is recommended to use linseed, and preferably natural drying oil.

That's all, the ax is ready. As a test, the author pricked with his help dry pine chocks. The ax coped with this task easily, hemp split into 4 parts at once. Of course, chopping thick logs and especially from hardwood with such an ax will be much more problematic. However, if you play with the mass of the ax, then perhaps it will cope with more complex tasks.