We live in a village, in the middle zone of Russia, here, far from heating plants and gas pipelines, stove heating dominates. By firewood. The most inexpensive, by the way, is the way to bask in the winter in our latitudes. And if we take into account the fact that wood is one of the few renewable sources of energy, then the matter has some sacred significance.

Furnaces for heating residential buildings, as a rule, are made heat-consuming; they are most able to maintain a comfortable microclimate indoors in the cold season. They are made of bricks with the thickness of the outer walls, most often half the standard clay brick, this is 120mm. Such furnaces, depending on the size (thermal power), can have a mass of several hundred to several thousand kilograms. Usually, the floors of residential buildings are not designed for such a load, and stoves are built on the foundation. On his own, on the stove.

I did not forget, and thank God, to put an ornament.

Well forgot? I forgot a little - to lay the foundation.

Here are those times! And by the way, listen, what’s wrong with that!

You can immediately destroy everything and build it again.

Mikhail Shcherbakov - Caryatids

The correct buried foundation for, say, a home, has a cost reaching one third of the cost of the entire structure. An impressive, in a word, expense item. For a conventional oven, no frills, apparently no less. Especially if there is a basement under the house, or for whatever reason the floors are high above the ground.

Exempt from the mandatory foundation of the furnace, weighing less than 750kg. It can be brick wood stoves, boilers, well, all sorts of metal dystrophics. They only need to further strengthen the floor.

Trustworthy authors, as a rule, give a single foundation scheme - deepened, for a furnace with a lightweight pipe, a depth of 1 m, with a mounted brick 1.2 m, is cast from concrete with layers of stone backing. Only in “Stove Works” by Y. G. Porfiryev, an alternative layout of a foundation made of slabs and brick walls on concrete soles is given.

The attention of the venerable public is offered a similar foundation in three versions. The stoves built on them have been working regularly for more than one year, no visible damage was noticed. The saving of materials is very significant, with a slight complication of the manufacturing process. There are no shortcomings inherent in similar (columnar, pile) foundations for buildings - there are difficulties with sealing and warming of the inter-pile space. For the foundations of furnaces, neither insulation nor sealing are required.

What was used.

Instruments.

Standard trench and marking tool for earthworks. A spade was very useful, somewhat more powerful than ordinary bayonets - a bunch of them broke. Cutting machine for cutting reinforcement. Sledgehammer, nowhere without her. A concrete mixer and associated ones were also used - a trough, buckets. Trowel of course. Levels, plumb line.

Materials

Fittings in proper quantity, knitting wire. Of course, the components for the preparation of concrete. Boards for formwork, fasteners. Boards, it is advisable to use which is not a pity - after concrete work they are of little use, even if the formwork is lined with a film or roofing material from the inside.

So, foundation for furnace No. 1. House. Heating and cooking stove. The basement is assumed, that is, the floor is quite high.

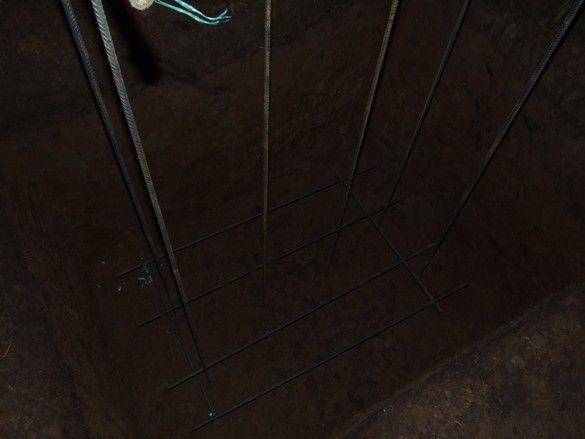

A pit of the appropriate size was dug in a previously carefully calculated place - so that the furnace pipe fell between the beam rafters and exited next to the ridge, but not on the ridge (unnecessary difficulties with the roof). Mounted reinforcement for the sole and three flat posts. The photo remained somehow dark, at night, or photographed, but you can disassemble it.

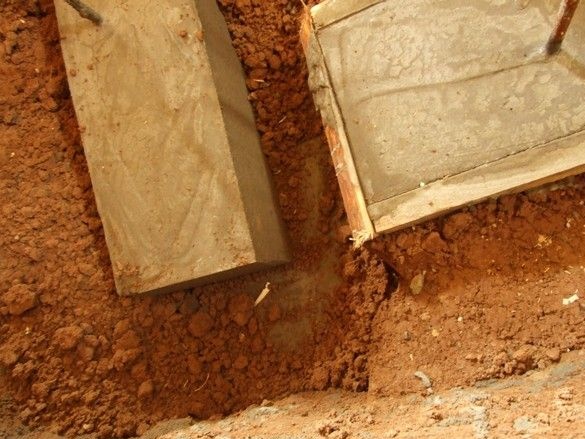

A sole plate with a thickness of just over 20 cm is cast. A few days later, the formwork was installed in place of the first column, after concreting it was moved to the place of the next and so on.

After removing the formwork, the concrete castings were not wrapped with a film - it was autumn and there was enough water in the form of constant rains.

The pit was littered with excavated soil, as it climbed. The formwork for the top plate was made and fixed.

I had to tinker, but the human mind won. Boards, boards, slivers, pieces of roofing material. Fasten all this so that after pouring it can be disassembled. Set relatively horizontally, fix the reinforcement - as much as is.

Small slots remained anyway, but with dense concrete, when it is not poured, but imposed, there were no significant losses. The stove was cast, quite expertly, with a soul. The formwork is disassembled, the edges of the slab are dulled with a brick so that they do not break off.

Later, in late autumn, we were put in a log house and on this, the construction season was over.

You can triple your skill, God be with you.

But breaking is not to build. So it is with fate.

Say a good, solid abode has come out,

But only himself can distinguish flaws builder.

If he’s principled, even in the midst of an ovation,

Even if a laudable noise is heard,

He will put his ambition away, not listening to the whine,

He walks away, looks, spits and takes a sledgehammer.

Mikhail Shcherbakov - the same Caryatids

But breaking is not to build. So it is with fate.

Say a good, solid abode has come out,

But only himself can distinguish flaws builder.

If he’s principled, even in the midst of an ovation,

Even if a laudable noise is heard,

He will put his ambition away, not listening to the whine,

He walks away, looks, spits and takes a sledgehammer.

Mikhail Shcherbakov - the same Caryatids

History deserves a preamble. Once we wintered in a house where, besides the stove, there was a fireplace. Yes, and quite beautiful, but the owners completely ignored him, they say, a lot of firewood was needed, but a little sense, on the contrary - a continuous draft. The inside of his pipe was plugged with an old quilted jacket from a draft and often heard talk about the need for him, a fireplace dismantling. Before making the foundation described above, looking for a suitable stove design for the house, remembering that ill-fated fireplace, all decorative excesses were rejected. Strictly in essence - heating and cooking, with an oven and all.After that, in the winter, I managed to get to visit our village houses, in the house where there was also a fireplace, a simple brick cube attached to the Russian stove, but how many praises the hosts sang for him ... In a word, I had to redo the foundation for a stove with a fireplace. Yes, yes, for a mad dog ... youthful enthusiasm, enthusiasm was still available.

With the help of magic crowbar and the mentioned sledgehammer, the top plate was, hmm ... dismantled, let's say. With the words, “I gave birth to you, I and you ...” I had to sweat.

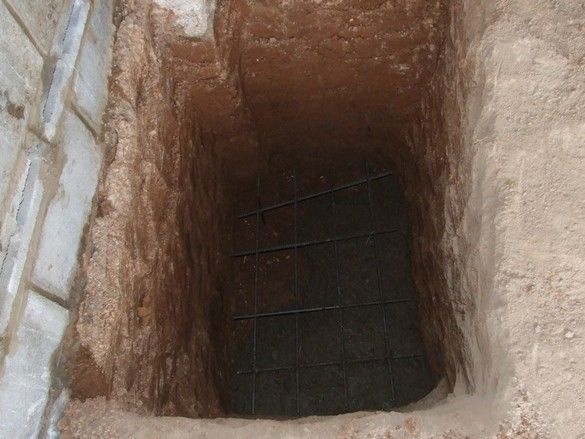

The foundation for the new furnace was recounted (a new pipe, between the beams, near the ridge), a hole of a new configuration was again broken to the bottom of the sole of the old foundation. It was in this, something from archeology.

An additional sole and smaller soles are poured. The task of the latter is to distribute the weight over a large area.

Four more similar columns were cast, their placement was somewhat not optimal, but there was nowhere to go.

Buried everything back, and again, healthy, formwork for the top plate. Even more complicated than before, but as Leah Akhidzhakova said, in the movie "Office Romance" - there is nothing impossible ... for a person with intelligence.

Here's a story, it was the very first foundation for the very first furnace. Kuznetsov, according to the classification adopted "from them" - OVIK_ZK_13_rec Heating and cooking, rear fireplace. The pipe is still metal. Yes, and the fireplace in the house is just wonderful.

The foundation for the bath stove.

It just so happened that our sauna stove was also supposed to be brick, not metal, but honestly made of brick, flue gases through a heater, all things. So, too - take it out, but lay the foundation. On the posts, of course.

Pit, fittings, sole casting. Sauna stove significantly less home, foundation, respectively, more miniature. Yes, the foundations of stoves are not connected with the foundation of the building.

By this time, at my disposal there were ready-made concrete blocks, 200x400x90mm in size. Presented as blocks for interior walls. It was decided to use them. The absence of the need to fence complex formwork made it possible to somewhat complicate the configuration of the “columns”, for stability they were laid out by a certain contour - a rectangle, slightly less than the perimeter of the upper and lower slabs.

"Columns". Laid out and buried. Shovel for scale to gauge depth. However, what is there to evaluate - five rows, 20 cm each, roughly speaking - 1 meter, plus the thickness of the sole. Here, unlike the house, there is no basement, and there is no need for strongly protruding columns, which greatly facilitates the installation of formwork for the top plate.

Inside, soil was also piled up, formwork was installed, a slab was cast.

The photo of the stove itself, alas, has not been preserved, this is waterproofing and the first row of the stove, well, as the classics said, by the power of your imagination ...

Yes, the stove has been operating for about a third year. The pipe is also metal. I hope temporarily.

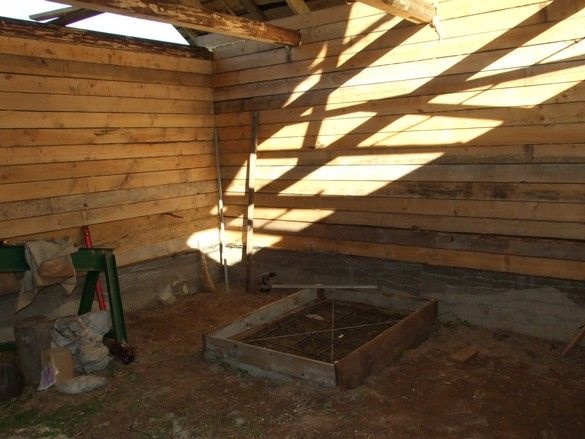

The foundation for the furnace in the workshop.

Well, there’s everything on the knurled surface - a foundation pit, fittings, outflow of the sole. In one breath.

Fortunately, there are still a few concrete bricks, which greatly simplifies the construction of "columns" and allows you not to mess with complex formwork.

The area is quite large - there will be a heating shield and some kind of experimental stove for it, in comparison with ordinary ones, several large dimensions.

The supports are finished, littered with soil, almost reaching the top, two layers of foam are laid on top. The usual balls.

The entire space under the top plate is lined with polystyrene flush with the supports. Polyfoam is needed to neutralize possible swelling of the soil during freezing.

The formwork this time, without any fancy, is put directly on the ground - not concrete work, but just some kind of holiday.

It is concreted in several steps. The perimeter inside the box and the cross from the cord is the level of the top of the plate.

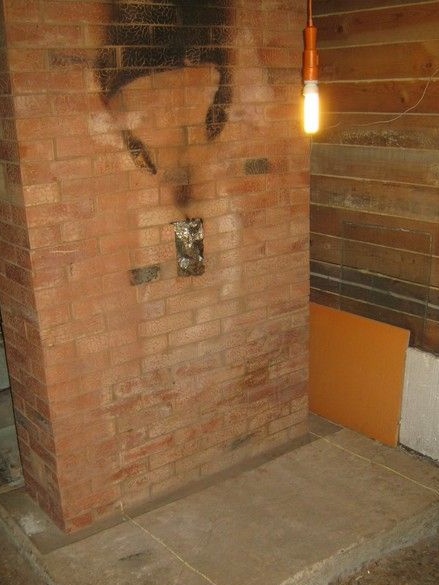

Top plate, already with a heating shield. Marked for the stove.

A bit unfinished slab - a couple more rows of lining, and wash it properly. Then I brag.