Problem: In a heap of wires, the essence is lost.

A couple of years ago, in the capital's Mitinsky market, a group of craftsmen offered an original service - custom-made flat cables. The length, number and color of the wires did not bother them. Unlike branded products, self-made only on one front side looked “real”, and the reverse surface was solid fused. Despite this cosmetic flaw, the service was in demand. Now they are not there, either they have changed the point, or business.

My personal interest in these guys was caused by the fact that in the late 80s, the desire to make modern-looking equipment and the lack of equipment from Electrotechprom prompted me to come up with the same thing. Since then, I have no problems with any kind of cable. I think this "discovery" was made then by many. In this case, it was interesting to see how a simple way at the level of rationalization feeds several people.

This is how I know how I propose here. Technology available. It is much faster to make the right flat cable for yourself than to buy an industrial one, even in Moscow.

You can use it in commerce - the niche for manufacturing flat cables to order is still empty.

Solution: the whole is always better than the sum of its parts and costs a lot more.

Flat cables are made of flexible multi-conductor mounting wire with PVC insulation and artificial silk winding. Type of wire MGShV. The connection of wires into a single flat cable design is carried out as a result of fusion of the outer polymer shells of wires. To carry out such fusion accurately, only in the gaps between the wires, is very difficult in simple ways. An acceptable result is continuous melting of the conductors on one side. Properly made cable in this way looks very good. In this case, the molten side of the cable is uniform and smooth. Markers can indicate the purpose of the cable and other information. The proposed technology does not give melt evenness, which is indifferent for single-color wires, but with multi-colored wires, the reverse side of the cable does not look quite branded.

The essence of the technology consists in the controlled melting of the upper layer of the bundle of wires with a hot object.

The quality of the final result largely depends on how well the wires are laid on the work surface. Wires should be tight and tightly pressed to each other. The working surface should be smooth, even.

I offer several tried and tested device options.

Option 1. As the working surface, a smooth board made of wood or chipboard is used. At the ends of the board are installed flat clamps on the screws. The wires are first fixed at one end of the board, and then stretched, leveled and secured with a second clamp.

Option 2 This option is used when you need to make two identical flat cables at once. The working board here has two working surfaces. If a cable is made of identical, single-color wires, then the wire is fixed at the end of the board, for example, on a nail driven into it or a slot. Then the wire is tightened wound on a board coil to coil and is also fixed on the end.

If necessary, make a pair of cables from multi-colored conductors, each conductor on the board is fixed separately. There are many ways to fix it. The simplest, in my opinion, is to tie the ends of the conductor thrown over the board and stretched.

Option 3 As a working surface, a table of suitable length is used. The method of laying the conductors and securing them is clear from the figure.

The most important part of the process, melting, is carried out with an ordinary iron. True, ironing does not go directly, but through a thin fluoroplastic film. This element is the core of the know how of the proposed process. Ftoroplast is a very heat-resistant polymer, its melting point is 327 degrees. A thin film (microns) conducts heat well, is transparent, which allows you to visually control the results of work. The iron glides well on the smooth surface of the fluoroplastic. The film does not adhere to the material in the molten sheath of the conductors.

PTFE film is widely used in the manufacture of critical winding products, like a dielectric in microwave devices. At the moment, it is not a deficit. Where can I get the film? For Moscow, the answer is simple - on the Mitinsky market. You can try searching in Tsaritsyno.

It is best to work not with the entire surface of the iron, but with its nose. I recommend that you first create "bridges" in several parts of the cable, which simplifies further work with it, preventing the divergence of conductors that may arise from pressure with an iron.

Experience comes with practice. Act - two - three cables and everything will be all right!

Result

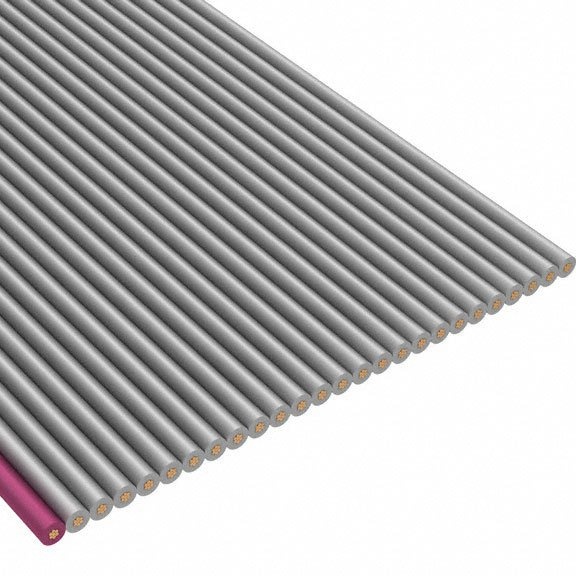

15 core cable Front side. Quality identical to industrial designs.

The blue wire gives the origin.

A characteristic view of the fused surface from the "wrong" side of the cable. The fusion line with the blue wire is clearly visible. Typical manufacturing defects associated with the melting of the plastic coating of the blue wire to the silk winding layer are noticeable.

Programmer PIC controllers with connecting cable 5 x 1 meter.

With single-color wires, surface quality is acceptable.

Debug adapter 9 x 60 cm.

Monochrome wires are used, and the initial wire is tinted with a black marker.