Hello everybody! I bring to your attention a "test bench" for craftsmen, electricians. This simple device will be useful not only for a beginner, but also for an experienced electrician who often has to repair faulty electrical appliances. The essence of this homemade product is to eliminate the short circuit home electrical networks when testing new electric homemade products or when repairing faulty electrical appliances. I will give a simple example. Suppose you brought a faulty vacuum cleaner, and what kind of malfunction is not yet clear. It is not possible to measure the load resistance with a simple tester, since the motor has a winding that is checked with a special device and not all masters have such. You turn on the faulty vacuum cleaner in the socket and it’s good that nothing will happen, and if there is a short circuit in your vacuum cleaner, the consequences can be very different from simply turning off the circuit breaker to the failure of your wiring and the worst fire. According to statistics, a very large number of fires comes precisely from poor wiring and faulty electrical appliances. Making this homemade product does not take much time and money, and in return is almost complete safety.

For manufacturing you will need:

Double circuit breaker 10 amp

Two outlets for outdoor installation

Dean rake

Wire no less than 1,5 sq. Mm

Electric plug

Screwdriver

Screws

Screwdriver

Nippers

Piece of plywood

Two outlets for outdoor installation

Dean rake

Wire no less than 1,5 sq. Mm

Electric plug

Screwdriver

Screws

Screwdriver

Nippers

Piece of plywood

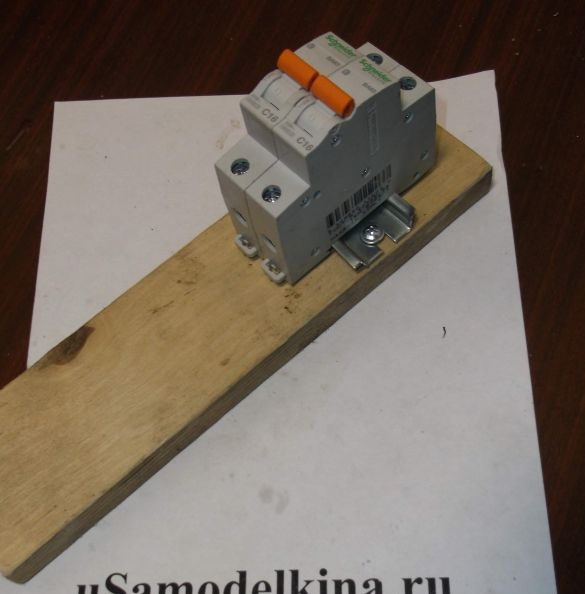

First, prepare the base on which it will be possible to fix all the details of the stand, namely two sockets, an automatic machine and a wire with a plug. You can choose any suitable material, in this case I took a piece of plywood 18 mm thick with dimensions of 25 by 6.5 centimeters.

On the prepared base we fix the din rail as in the photo. You need to step back from the top as much as you need to install the machines and secure the wire.

The circuit breaker can be installed double or two single, as in the photo, with a rated current of 6 or 10 amperes, although this is not important. In this scheme, the machine plays a secondary role - as an additional protection and as a conventional switch.

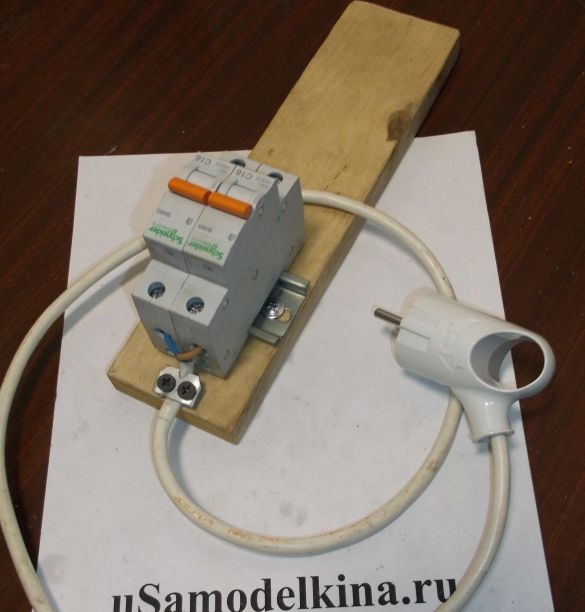

We connect an electric wire with a plug to the machine and fix it to the base using self-tapping screws and a tin bracket.

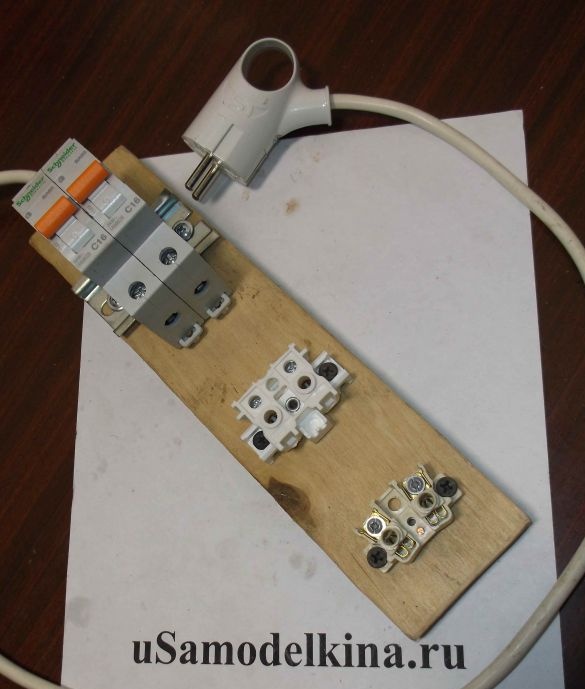

Next, we mark and attach to the base the mechanisms of the outlets.

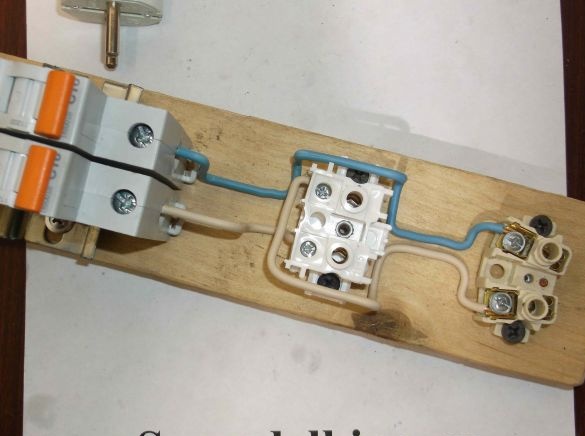

Now you need to connect the sockets to the machine, the whole secret of this homemade product lies in the connection. We will not connect in parallel as in ordinary socket blocks - in parallel, but in series. The photo shows how to connect both sockets.

The principle of operation is simple, a deliberately operational electrical appliance of greater power than the test one is connected to one outlet, and accordingly, to the second, it is faulty. Even in the event of a short circuit in a faulty electrical appliance, the second obviously working electrical appliance will simply operate according to the rated power, therefore, no electrical fault or overload will occur. I think the essence of this homemade product is understandable.

We install the housing of the outlets.

When connected, the wires are mounted at a certain distance from each other for the possibility of connecting clamp meters.

Based on the testimony of connected clamp meters, it is possible to more accurately determine the nature of damage to the tested electrical appliance.

In the previously described example of repairing a vacuum cleaner, for a working load, you can connect, for example, a load of a couple of kilowatts (I connect an iron). If the iron is cold - a breakage should be found in the vacuum cleaner, if the iron heats up, and our vacuum cleaner does not show signs of life, then the patient has a high probability of a short circuit, and if the iron heats up and the vacuum cleaner works at half power, then it’s possible no repairs needed. The main thing as a working electrical appliance is to choose one that can easily withstand your wiring.

By the same principle, new home-made products can be tested, for example, a 220-volt transformer wound around their hands.

With this homemade product, there is simply no chance to arrange a short circuit.